In the competitive landscape of 2025, the global composite market has shifted. Whether you are manufacturing wind turbine blades, automotive components, or FRP (Fiber Reinforced Polymer) pipes, the reliability of your fiberglass roving supplier is no longer just a procurement detail—it is a strategic cornerstone.

As production speeds increase and quality tolerances tighten, simply buying the “cheapest” roving can lead to catastrophic failures, high scrap rates, and damaged machinery. To secure your supply chain, here are the seven critical factors you must evaluate when auditing a potential partner.

1. Chemical Sizing and Resin Compatibility

The “sizing” (the chemical coating on the glass fiber) is the most critical technical aspect of fiberglass roving. It acts as a chemical bridge between the inorganic glass and the organic resin.

The Risk: Using a roving with a sizing optimized for Polyester in an Epoxy resin system will result in poor “wet-out” and weak interlaminar shear strength.

The Evaluation: Does the supplier offer specialized sizings for your specific process (e.g., Silane-based for thermoplastics vs. starch-based for specific textile uses)? Ask for compatibility matrices and resin absorption test results.

2. Consistency of Tex and Filament Diameter

In high-speed processes like pultrusion or filament winding, consistency is king. If the Tex (linear density) fluctuates significantly, your final product’s glass-to-resin ratio will vary, leading to structural weak spots.

Fuzz and Breakage: Low-quality suppliers often have “fuzzy” roving—broken filaments that accumulate in your guides and tensioners. This causes frequent downtime and weakens the reinforcement.

Audit Tip: Request the supplier’s CPK (Process Capability Index) data for Tex consistency over a 12-month period.

3. Production Capacity and Scalability

A supplier that is great for a 5-ton order might fail you on a 500-ton contract. In the current global climate, supply chain resilience is paramount.

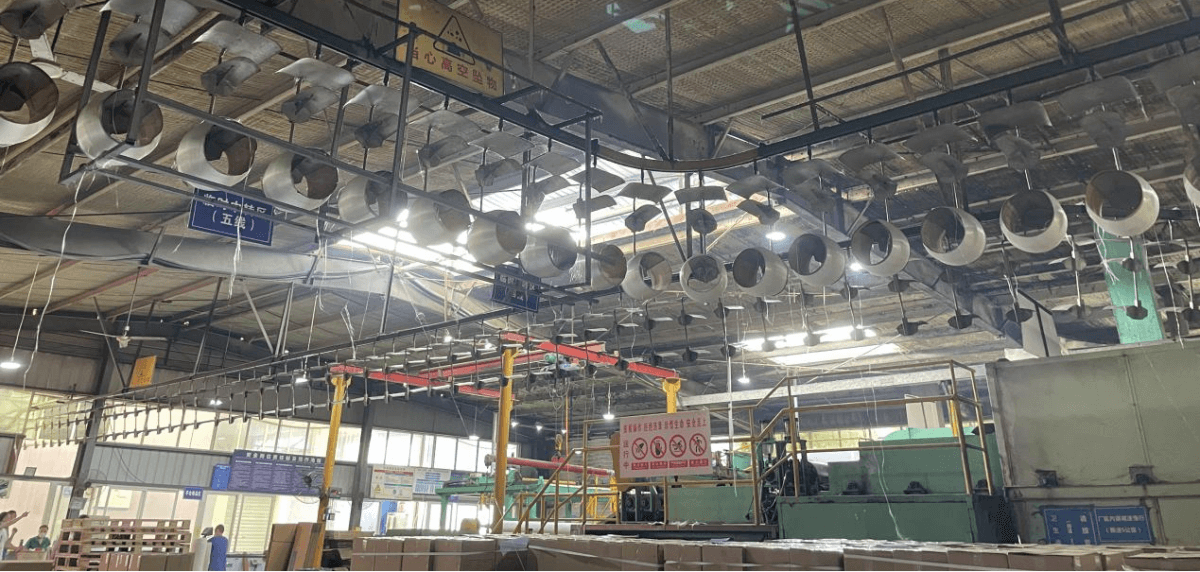

Volume: Does the manufacturer have multiple furnaces? If one furnace goes down for maintenance, can they shift production to another line without delaying your shipment?

Lead Times: A reliable partner should provide clear, data-backed lead times and have a logistics network capable of navigating international shipping disruptions.

Comparative Analysis: What Separates a Strategic Partner?

To help your procurement team make a faster decision, use the table below to differentiate between a high-tier strategic partner and a basic commodity vendor.

Supplier Evaluation Matrix

|

Evaluation Factor |

Tier 1: Strategic Partner |

Tier 2: Commodity Vendor |

|

Technical Support |

On-site engineers and custom sizing development. |

Email-only support; “off-the-shelf” products only. |

|

Quality Control |

Real-time monitoring with ISO 9001 & UL certifications. |

Batch testing only; inconsistent documentation. |

|

R&D Capability |

Active development of High-Modulus (HM) fibers. |

Sells standard E-glass only. |

|

Packaging |

UV-stabilized shrink wrap; moisture-barrier pallets. |

Basic plastic wrap; prone to moisture ingress. |

|

ESG Compliance |

Transparent carbon footprint and waste recycling. |

No environmental reporting. |

|

Logistics |

Integrated tracking and multi-port shipping options. |

Ex-works (EXW) only; limited shipping support. |

4. Rigorous Quality Control and Traceability

In industries like aerospace or infrastructure, traceability is non-negotiable. Every bobbin of glass fiber roving should be traceable back to the specific furnace, the raw material batch, and the shift during which it was produced.

Certifications: Ensure they hold ISO 9001:2015, and if you are in the marine or wind sector, look for DNV-GL or Lloyd’s Register certifications.

Testing Labs: A top-tier supplier will have an in-house lab to test tensile strength, moisture content, and ignition loss (LOI) before any pallet leaves the warehouse.

5. Advanced Packaging and Moisture Protection

Fiberglass is highly sensitive to the environment before it is processed. If a bobbin absorbs moisture during sea transit, the sizing chemistry can degrade, leading to poor bonding.

The Standard: Look for suppliers who use vertical palletization with individual bobbin protection, heavy-duty shrink wrapping, and desiccant packs.

Storage Advice: Evaluate if the supplier provides clear guidelines on storage temperatures and humidity to ensure the 6–12 month shelf life of the fiberglass roving is maintained.

6. ESG and Environmental Sustainability

As global regulations like the EU’s Carbon Border Adjustment Mechanism (CBAM) take effect, the “green” credentials of your supplier will impact your bottom line.

Energy Efficiency: Does the manufacturer use oxygen-fuel combustion in their furnaces to reduce CO2?

Waste Management: High-tier suppliers recycle their glass waste into other construction materials, helping you meet your own corporate sustainability goals.

7. R&D and Customization Capabilities

The composites industry is moving toward “specialization.” Whether it’s alkali-resistant (AR) glass for concrete or high-tensile roving for pressure vessels, you need a supplier that can innovate.

The Customization Test: Ask the supplier: “Can you adjust the filament diameter from 13μm to 17μm for our specific pultrusion die?” A true manufacturer will engage in a technical discussion; a trader will tell you they only have one size.

Conclusion: The “Hidden Cost” of Cheap Roving

When choosing a fiberglass roving supplier, the invoice price is only 20% of the story. The remaining 80% is found in production efficiency, product longevity, and technical support. By auditing your potential partners against these seven factors, you ensure that your manufacturing line remains uninterrupted and your products remain world-class.

At CQDJ, we pride ourselves on being more than just a manufacturer. We are a technical partner dedicated to the science of reinforcement. Our facilities are optimized for high-volume, high-consistency production with a focus on sustainable manufacturing.

Post time: Dec-30-2025