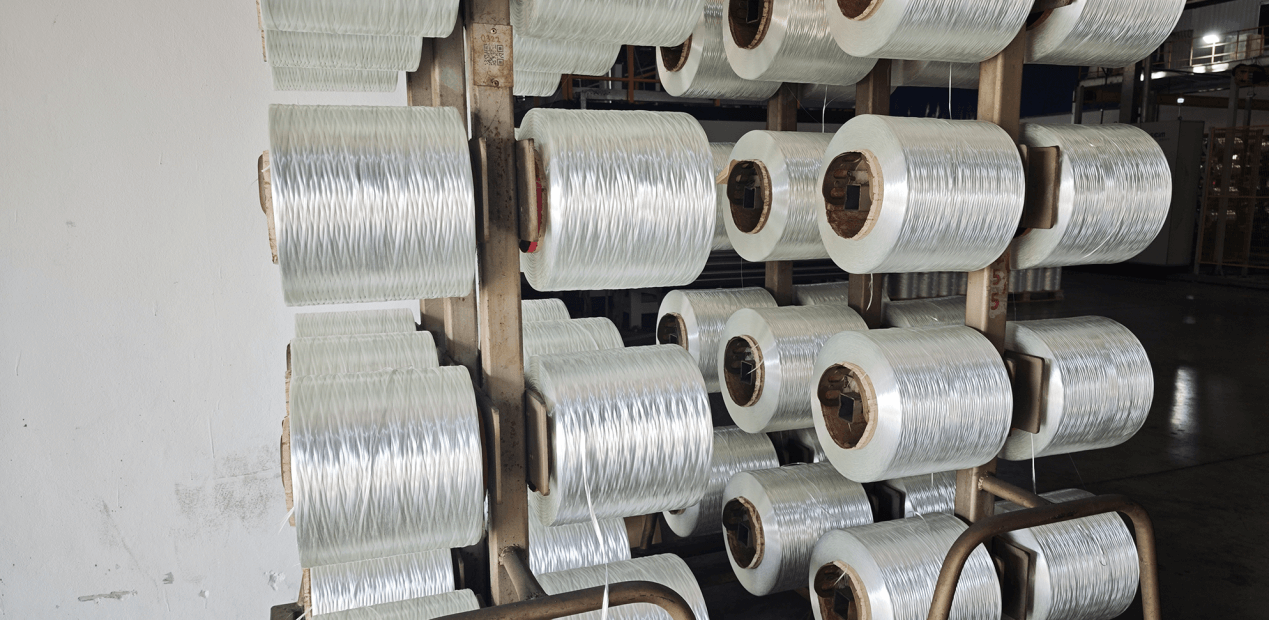

In the rapidly evolving landscape of the global automotive industry, the race toward electric mobility (EV) and fuel efficiency has fundamentally shifted the focus from engine performance to material science. At the heart of this transformation lies the concept of Automotive Lightweighting. While advanced alloys and carbon fiber often steal the headlines, fiberglass roving has emerged as the unsung hero, providing a cost-effective, high-performance solution for manufacturing next-generation vehicle components.

The Strategic Shift: Why Fiberglass Roving?

The automotive sector is currently facing a dual challenge: reducing carbon emissions for internal combustion engine (ICE) vehicles and extending the battery range for Electric Vehicles (EVs). Weight reduction is the most effective lever to pull for both. Industry data suggests that a 10% reduction in vehicle weight can lead to a 6–8% improvement in fuel economy or a significant increase in EV mileage.

Fiberglass roving, particularly direct roving and assembled roving, offers a unique set of properties that make it indispensable for modern Tier-1 suppliers:

Exceptional Strength-to-Weight Ratio: Despite being significantly lighter than steel or aluminum, components reinforced with glass fiber roving can withstand immense mechanical stress.

Corrosion Resistance: Unlike metals, fiberglass does not rust, extending the lifespan of chassis and underbody components.

Design Flexibility: The use of roving in processes like pultrusion and SMC (Sheet Molding Compound) allows for complex geometries that are impossible to achieve with traditional metal stamping.

Key Applications in Next-Gen Vehicles

The versatility of fiberglass roving is best demonstrated through its diverse applications in modern vehicle architecture.

1. EV Battery Enclosures

As the heaviest component in an electric vehicle, the battery pack requires a housing that is not only lightweight but also fire-retardant and electromagnetically shielded. Fiberglass roving, when combined with specialized thermoset resins, creates a composite enclosure that protects the battery cells while contributing to the overall structural rigidity of the car.

2. Leaf Springs and Suspension Systems

Traditional steel leaf springs are heavy and prone to fatigue. By utilizing high-modulus fiberglass roving in a pultrusion process, manufacturers can produce composite leaf springs that are up to 75% lighter than their steel counterparts, offering better dampening properties and a smoother ride.

3. Underbody Shields and Structural Brackets

The underbody of a vehicle is exposed to harsh road debris and moisture. Fiberglass-reinforced thermoplastics (CFRTP) using long fiber roving provide superior impact resistance, protecting the vehicle’s “vital organs” without adding the bulk of heavy metal shielding.

The Role of Advanced Roving Technology: E-Glass vs. High-Modulus Glass

To meet the stringent demands of the automotive industry, not all fiberglass roving is created equal. The choice of fiber determines the end-performance of the part.

E-Glass Roving: The industry standard, offering excellent electrical insulation and mechanical properties at a competitive price point. It remains the go-to for standard interior and exterior panels.

High-Modulus (HM) Roving: For structural components that require extreme stiffness, such as roof pillars or door frames, HM roving provides a modulus that bridges the gap between traditional glass fiber and expensive carbon fiber.

At [CQDJ], we specialize in producing fiberglass roving with advanced sizing systems—the chemical coating applied to the fibers. Our proprietary sizing ensures a perfect bond between the fiber and the resin matrix (whether it be Epoxy, Polyester, or Polypropylene), which is critical for preventing delamination and ensuring long-term durability in high-vibration automotive environments.

Sustainability: The Circular Economy of Glass Fiber

A common misconception is that composites are not eco-friendly. However, the move toward thermoplastic roving (TP) is changing the narrative. Unlike thermosets, thermoplastic-impregnated roving can be melted and reshaped, opening the door for the recycling of automotive parts at the end of the vehicle’s life cycle. Furthermore, the energy required to produce fiberglass roving is significantly lower than that of aluminum or carbon fiber, reducing the “embedded carbon” of the vehicle from day one.

SEO Insights for Procurement Managers

When sourcing fiberglass roving for automotive applications, it is no longer enough to look at “price per ton.” Procurement teams are now focusing on:

1.Tensile Strength (MPa): Ensuring the fiber can handle the load.

2.Compatibility: Does the roving work with specific resin systems (PA6, PP, or Epoxy)?

3.Consistency: Does the roving offer uniform tension and minimal fuzz, preventing downtime in automated production lines?

Conclusion

The future of the automotive industry is lighter, stronger, and more sustainable. As we move deeper into the decade, the integration of fiberglass roving into structural and functional vehicle parts will only accelerate. By replacing heavy metals with high-performance composites, manufacturers are not just building cars; they are engineering the future of mobility.

How We Can Help

As a leading manufacturer of high-performance fiberglass roving, [CQDJ] provides tailored solutions for the automotive supply chain. Our products are engineered to optimize pultrusion, SMC, and LFT (Long Fiber Thermoplastic) processes.

Post time: Dec-19-2025