Introduction

Fiberglass roving is a key reinforcement material in composites, but choosing between direct roving and assembled roving can significantly impact performance, cost, and manufacturing efficiency. This in-depth comparison explores their differences, advantages, and best applications to help you make the right choice.

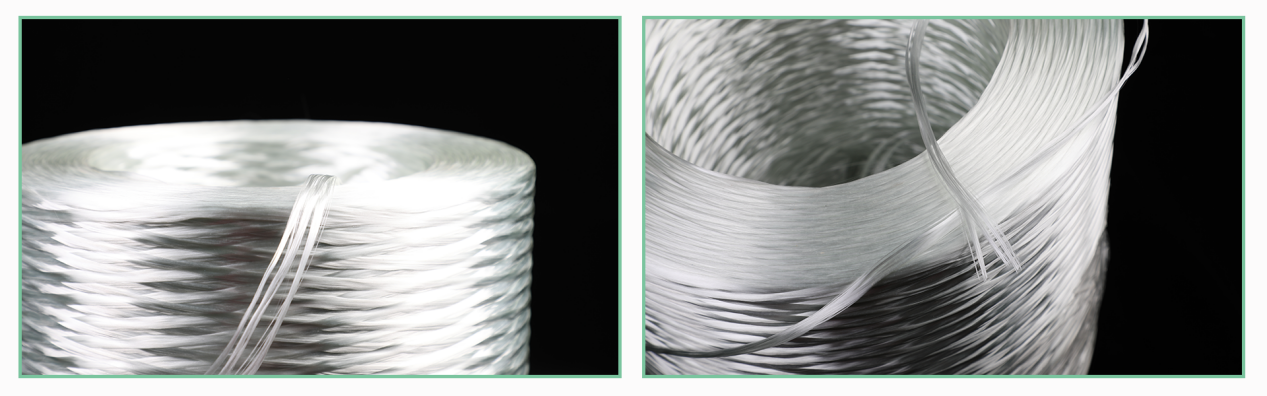

What Is Fiberglass Direct Roving?

Fiberglass direct roving is manufactured by drawing continuous glass filaments directly from a furnace, then bundling them into strands without twisting. These rovings are wound onto bobbins, ensuring uniform thickness and high tensile strength.

Key Features:

✔ High strength-to-weight ratio

✔ Excellent resin compatibility (quick wet-out)

✔ Consistent filament alignment (better mechanical properties)

✔ Ideal for automated processes (pultrusion, filament winding)

What Is Fiberglass Assembled Roving?

Assembled roving is made by gathering multiple smaller strands (often twisted) into a larger bundle. This process can introduce slight variations in thickness but improves handling in certain applications.

Key Features:

✔ Better drapeability (useful for hand lay-up)

✔ Reduced fuzz generation (cleaner handling)

✔ More flexible for complex molds

✔ Often cheaper for manual processes

Direct Roving vs. Assembled Roving: Key Differences

| Factor | Direct Roving | Assembled Roving |

| Manufacturing | Filaments drawn directly | Multiple strands bundled |

| Strength | Higher tensile strength | Slightly lower due to twists |

| Resin Wet-Out | Faster absorption | Slower (twists hinder resin) |

| Cost | Slightly higher | More economical for some uses |

| Best For | Pultrusion, filament winding | Hand lay-up, spray-up |

Which One Should You Choose?

When to Use Fiberglass Direct Roving

✅ High-performance composites (wind turbine blades, aerospace)

✅ Automated production (pultrusion, RTM, filament winding)

✅ Applications needing maximum strength & stiffness

When to Use Assembled Roving

✅ Manual processes (hand lay-up, spray-up)

✅ Complex molds requiring flexibility

✅ Cost-sensitive projects

Industry Applications Compared

1. Automotive Industry

Direct roving: Structural parts (leaf springs, bumper beams)

Assembled roving: Interior panels, non-structural components

2. Construction & Infrastructure

Direct roving: Rebar, bridge reinforcements

Assembled roving: Decorative panels, lightweight facades

3. Marine & Aerospace

Direct roving: Hulls, aircraft components (high strength needed)

Assembled roving: Smaller boat parts, interior linings

Expert Opinions & Market Trends

According to John Smith, Composites Engineer at Owens Corning:

“Direct roving dominates automated manufacturing due to its consistency, while assembled roving remains popular in manual processes where flexibility is key.”

Market Data:

The global fiberglass roving market is projected to grow at 6.2% CAGR (2024-2030).

Direct roving demand is rising due to increased automation in wind energy and automotive sectors.

Conclusion: Which One Wins?

There’s no universal “better” option—it depends on your project’s needs:

For high strength & automation → Direct roving

For manual work & cost savings → Assembled roving

By understanding these differences, manufacturers can optimize performance, reduce waste, and improve ROI in composite production.

Post time: Jul-10-2025