Introduction

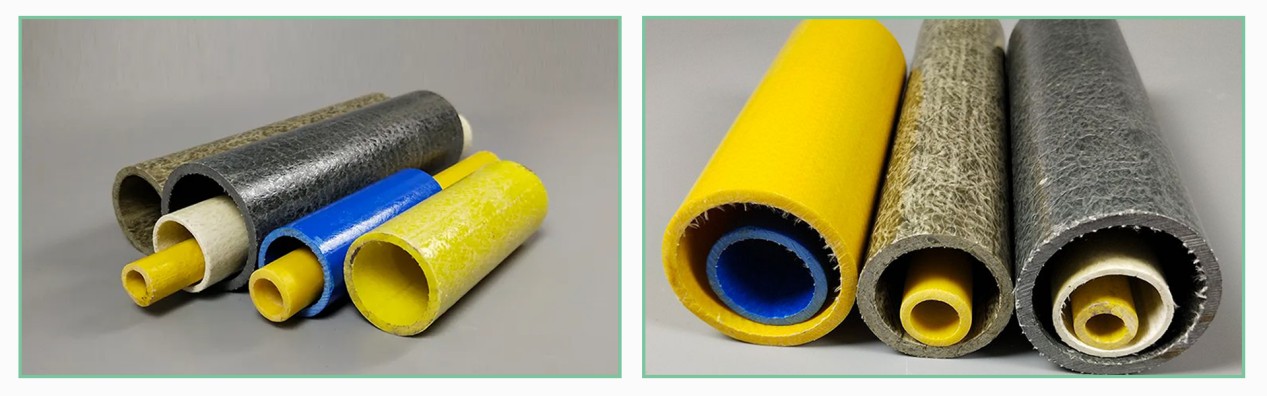

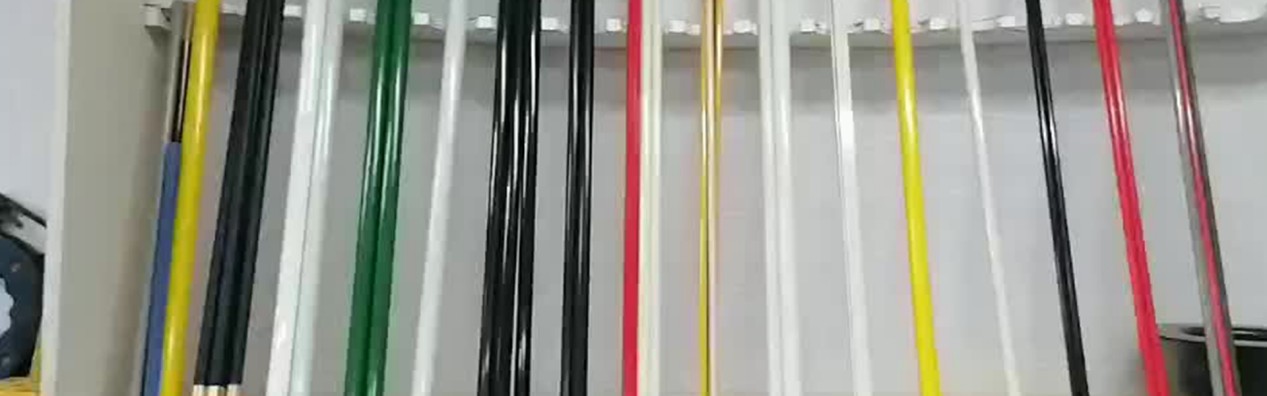

Fiberglass tubes are widely used in industries such as marine, construction, aerospace, and chemical processing due to their lightweight, corrosion resistance, and high strength-to-weight ratio. However, like any material, proper maintenance and care are essential to maximize their lifespan and performance.

This guide covers best practices for maintaining fiberglass tubes, including cleaning, inspection, repair methods, and storage tips, ensuring they remain durable for years to come.

1. Regular Cleaning and Debris Removal

Why Cleaning Matters

Dirt, chemicals, and salt deposits can accumulate on fiberglass tubes, leading to:

Surface degradation

Reduced structural integrity

Potential chemical reactions

Cleaning Methods

For General Dirt & Dust

Use mild soap and water with a soft brush or cloth.

Avoid abrasive cleaners that can scratch the surface.

For Saltwater Exposure (Marine Applications)

Rinse with fresh water after exposure to prevent salt buildup.

Use a vinegar-water solution (50/50) to remove salt deposits.

For Chemical Contamination

Use isopropyl alcohol or specialized fiberglass cleaners.

Always check chemical compatibility before application.

Pro Tip: Avoid high-pressure washing, as it can damage the resin coating.

2.Routine Inspection for Damage

What to Look For

Regular inspections help detect early signs of wear, including:

✔ Cracks or fractures – Especially near joints and stress points.

✔ Delamination – Separation of fiberglass layers.

✔ UV Damage – Fading or brittleness from sun exposure.

✔ Chemical Erosion – Discoloration or softening.

Inspection Frequency

Industrial Use: Every 3–6 months.

Marine & Outdoor Use: Every 1–3 months.

High-Stress Applications (Aerospace, Automotive): Before and after each use.

3. Repairing Minor Damage

Small Cracks & Chips

Sand the area lightly with 120-grit sandpaper.

Clean with acetone to remove dust and oils.

Apply fiberglass repair resin and let it cure.

Sand smooth and repaint if necessary.

Delamination Repair

Drill small holes around the affected area to prevent spreading.

Inject epoxy resin into the gaps.

Clamp and cure for 24 hours.

For Major Damage: Consult a professional fiberglass repair service.

4. Protecting Against UV Degradation

Why UV Protection is Critical

Prolonged sun exposure can cause:

Yellowing or fading

Surface brittleness

Reduced structural strength

Solutions for UV Resistance

✓ Gel Coat or UV-Resistant Paint – Apply a protective layer.

✓ Store Indoors or Use Covers – When not in use.

✓ Add UV Inhibitors – Some fiberglass tubes come with built-in UV protection.

5. Proper Storage Practices

Ideal Storage Conditions

Keep in a dry, cool place (avoid extreme temperature changes).

Store horizontally on racks to prevent warping.

Avoid stacking heavy objects on top.

For Long-Term Storage

Wrap tubes in breathable fabric (not plastic, which traps moisture).

Use silica gel packs to prevent humidity damage.

6. Avoiding Common Mistakes That Shorten Lifespan

✕ Using Harsh Chemicals – Can weaken resin bonds.

✕ Ignoring Small Cracks – Leads to bigger structural failures.

✕ Improper Handling – Dropping or bending beyond design limits.

7. When to Replace Fiberglass Tubes

Even with proper maintenance, fiberglass tubes may need replacement if:

⚠ Deep cracks or fractures compromise structural integrity.

⚠ Severe delamination cannot be repaired.

⚠ Excessive UV or chemical damage weakens the material.

Conclusion: Maximizing Your Fiberglass Tube Investment

By following these maintenance and care tips, you can:

✔ Extend the lifespan of fiberglass tubes by years.

✔ Reduce repair and replacement costs.

✔ Ensure optimal performance in demanding environments.

For high-quality, durable fiberglass tubes, explore Chongqing Dujiang Composites Co., Ltd.’s range of products—engineered for longevity and reliability.

Post time: May-22-2025