In the vast landscape of advanced materials, few are as versatile, robust, and yet as understated as fiberglass tape. This unassuming product, essentially a woven fabric of fine glass fibers, is a critical component in some of the most demanding applications on the planet—from holding together skyscrapers and spacecraft to ensuring your smartphone’s circuitry stays protected. While it may lack the glamour of carbon fiber or the buzzword status of graphene, fiberglass tape is an engineering powerhouse, offering an unparalleled combination of strength, flexibility, and resistance to the elements.

This article delves deep into the world of fiberglass tape, exploring its manufacturing, its key properties, and its transformative applications across diverse industries. We will uncover why this material has become the unseen backbone of modern innovation and what future developments are on the horizon.

What Exactly is Fiberglass Tape?

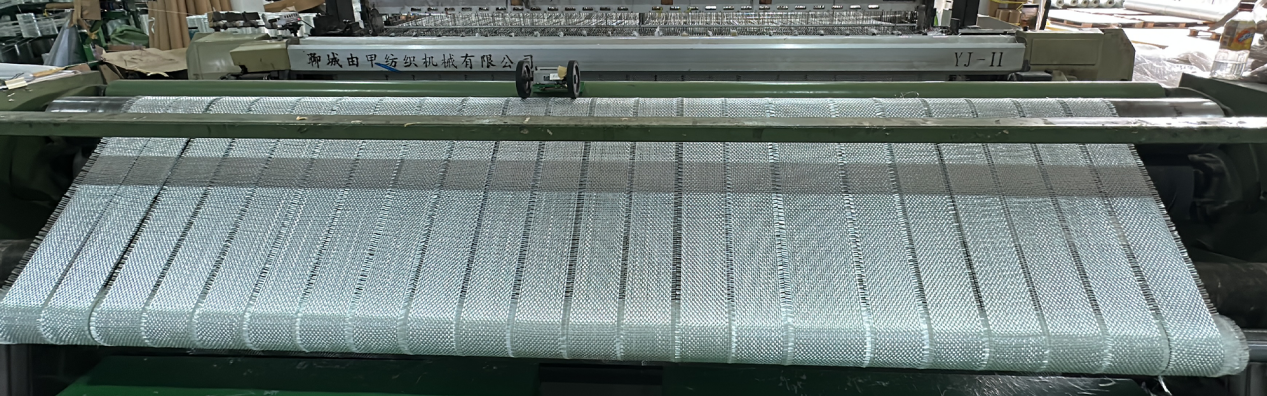

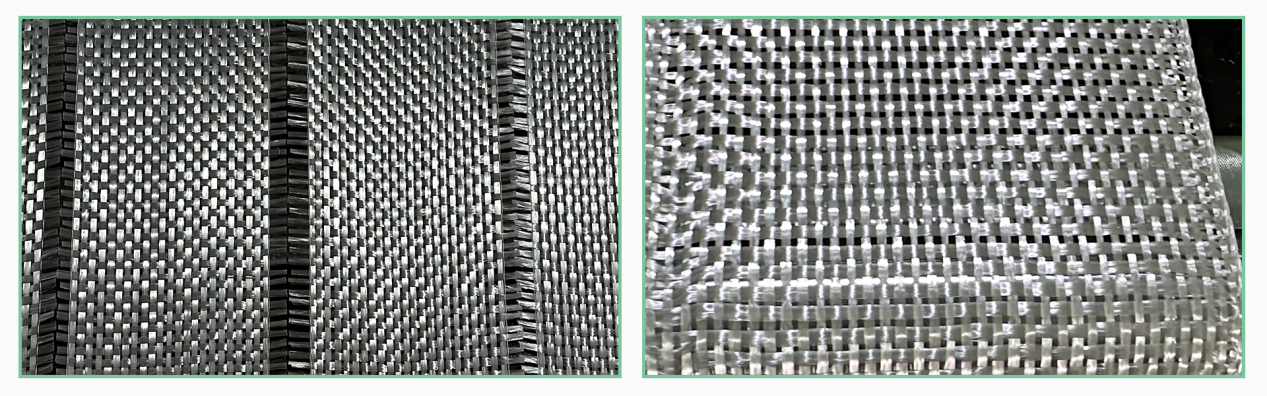

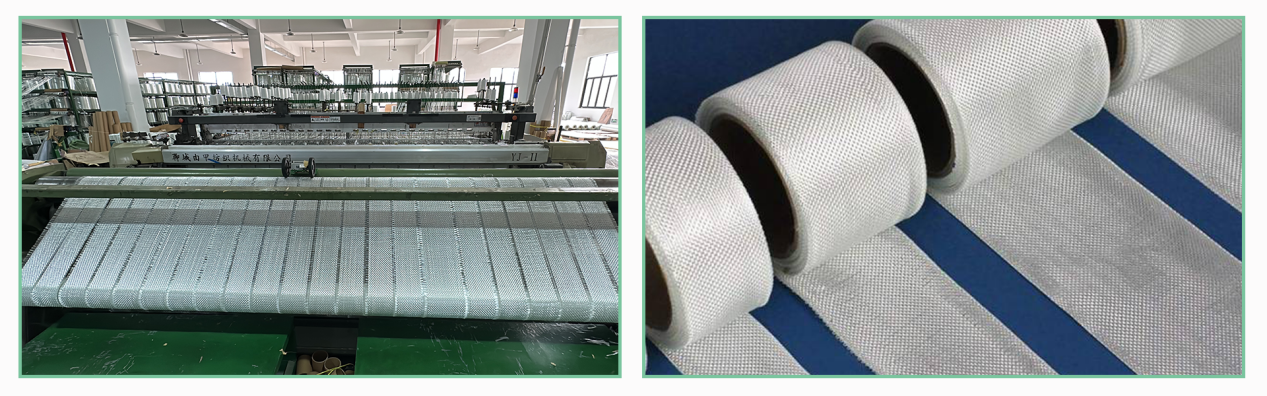

At its core, fiberglass tape is a material made from woven glass filaments. The process begins with the production of the glass fibers themselves. Raw materials like silica sand, limestone, and soda ash are melted at extremely high temperatures and then extruded through ultra-fine bushings to create filaments thinner than a human hair. These filaments are then spun into yarns, which are subsequently woven on industrial looms into a tape format of various widths.

The tape itself can be supplied in different forms:

● Plain Weave: The most common, offering a good balance of stability and flexibility.

● Unidirectional: Where the majority of fibers run in one direction (the warp), providing extreme tensile strength along the tape’s length.

● Saturated or Pre-impregnated (“Pre-preg”): Coated with a resin (like epoxy or polyurethane) that is later cured under heat and pressure.

● Pressure-Sensitive: Backed with a strong adhesive for instant stick applications, commonly used in drywall and insulation.

It is this versatility in form that allows fiberglass tape to serve such a wide array of functions.

Key Properties: Why Fiberglass Tape is an Engineer’s Dream

The popularity of fiberglass tape stems from a unique set of physical and chemical properties that make it superior to many alternative materials like steel, aluminum, or organic fabrics.

Exceptional Tensile Strength: Pound for pound, covering material is considerably stronger than steel. This high strength-to-weight quantitative relation is its most prized attribute, letting reinforcement while not adding substantial weight.

Dimensional Stability: Fiberglass tape does not stretch, shrink, or warp under varying temperature and humidity conditions. This stability is crucial for applications requiring long-run exactitude.

High Heat Resistance: As a mineral-based material, it is inherently non-flammable and can withstand continuous high-temperature exposure without degrading, making it ideal for thermal insulation and fire protection systems.

Chemical Resistance: It is highly resistant to most acids, alkalis, and solvents, preventing corrosion and degradation in harsh chemical environments.

Electrical Insulation: Fiberglass is an excellent electrical insulator, a property that is paramount in the electronics and electrical utility industries.

Moisture and Mold Resistance: Unlike organic materials, it does not absorb water or support mold growth, ensuring longevity and structural integrity in damp conditions.

Transformative Applications Across Industries

1. Construction and Building: The Cornerstone of Modern Structures

In the construction industry, fiberglass tape is indispensable. Its primary use is in reinforcing drywall seams and corners. Fiberglass mesh tape, combined with joint compound, creates a strong, monolithic surface that is far less likely to crack over time than paper tape, especially as a building settles. Its mold resistance is a critical benefit in areas prone to moisture.

Beyond drywall, it is used in:

● Stucco and EIFS Reinforcements: Embedded in exterior plaster systems to prevent cracking.

● Foundation and Concrete Crack Repair: High-tensile tapes are used to stabilize and seal cracks.

● Pipe Wrapping: For insulation and corrosion protection on pipes.

● Roofing and Waterproofing Membranes: Reinforcing asphalt-based or synthetic roofing materials to enhance tear resistance.

2. Composite Manufacturing: Building Stronger, Lighter Products

The world of composites is where fiberglass tape truly shines. It is a fundamental reinforcement material used in conjunction with resins to create incredibly strong and lightweight composite parts.

● Aerospace and Aviation: From the interiors of commercial airliners to the structural components of unmanned aerial vehicles (UAVs), fiberglass tape is used to create parts that must be incredibly light yet able to withstand immense stress and vibration. Its use in ducting, radomes, and fairings is widespread.

● Marine Industry: Boat hulls, decks, and other components are often built using fiberglass tape and cloth. Its resistance to brine corrosion makes it so much superior to metal for several marine applications.

● Automotive and Transportation: The push for lighter, more fuel-efficient vehicles has led to increased use of composite materials. Fiberglass tape reinforces body panels, interior components, and even high-pressure tanks for natural gas vehicles.

● Wind Energy: The huge blades of wind turbines square measure primarily made from covering material composites. Unidirectional fiberglass tape is laid up in specific patterns to handle the enormous bending and torsional loads experienced by the blades.

3. Electronics and Electrical Engineering: Ensuring Safety and Reliability

The electrical properties of covering material tape create it a default alternative for safety and insulation.

● PCB (Printed Circuit Board) Manufacturing: The substrate of most PCBs is made from woven fiberglass cloth impregnated with an epoxy resin (FR-4). This provides a rigid, stable, and insulating foundation for electronic circuits.

● Motor and Transformer Insulation: It is used to wrap and insulate copper windings in electric motors, generators, and transformers, protecting against short circuits and high temperatures.

● Cable Harnessing and Splicing: In the telecommunications and power utility sectors, fiberglass tape is used to bundle and protect cables and for splicing high-voltage lines, thanks to its dielectric strength.

4. Specialty and Emerging Applications

The utility of fiberglass tape continues to expand into new frontiers.

● Thermal Protection: Satellites and spacecraft use specialized high-temperature fiberglass tapes as part of their thermal protection systems.

● Personal Protective Equipment (PPE): It is used in the manufacturing of heat-resistant gloves and clothing for welders and firefighters.

● 3D Printing: The additive manufacturing industry is increasingly using continuous fiber reinforcement (CFR). Here, fiberglass tape or filament is fed into a 3D printer alongside plastic, resulting in parts with strength comparable to aluminum.

The Future of Fiberglass Tape: Innovation and Sustainability

The future of fiberglass tape is not stagnant. Research and development are focused on enhancing its properties and addressing environmental concerns.

● Hybrid Tapes: Combining fiberglass with other fibers like carbon or aramid to create tapes with tailored properties for specific high-performance needs.

● Eco-Friendly Sizings and Resins: Development of bio-based and less environmentally impactful coatings and resins for the tape.

● Recycling: As composite usage grows, so does the challenge of end-of-life waste. Significant research is being dedicated to developing efficient methods to recycle fiberglass composites.

● Smart Tapes: Integration of sensor fibers into the weave to create “smart” tapes that can monitor strain, temperature, or damage in real-time within a structure—a concept with huge potential for aerospace and infrastructure.

Conclusion: An Indispensable Material for a Advanced World

Fiberglass tape is a quintessential example of a enabling technology—one that works behind the scenes to make greater innovations possible. Its unique blend of strength, stability, and resistance has cemented its role as a critical material in shaping our modern built environment, from the homes we live in to the vehicles we travel in and the devices we communicate with.

As industries continue to push the boundaries of performance, efficiency, and sustainability, the humble fiberglass tape will undoubtedly continue to evolve, remaining an indispensable and revolutionary force in engineering and manufacturing for decades to come. It is the unseen backbone, and its importance cannot be overstated.

Post time: Sep-29-2025