Introduction

Fiberglass mesh is a crucial material in construction, particularly for reinforcing walls, preventing cracks, and improving durability. However, with various types and qualities available in the market, selecting the right fiberglass mesh can be challenging. This guide provides expert insights on how to choose the best quality fiberglass mesh, ensuring long-lasting performance for your projects.

1. Understanding Fiberglass Mesh: Key Features

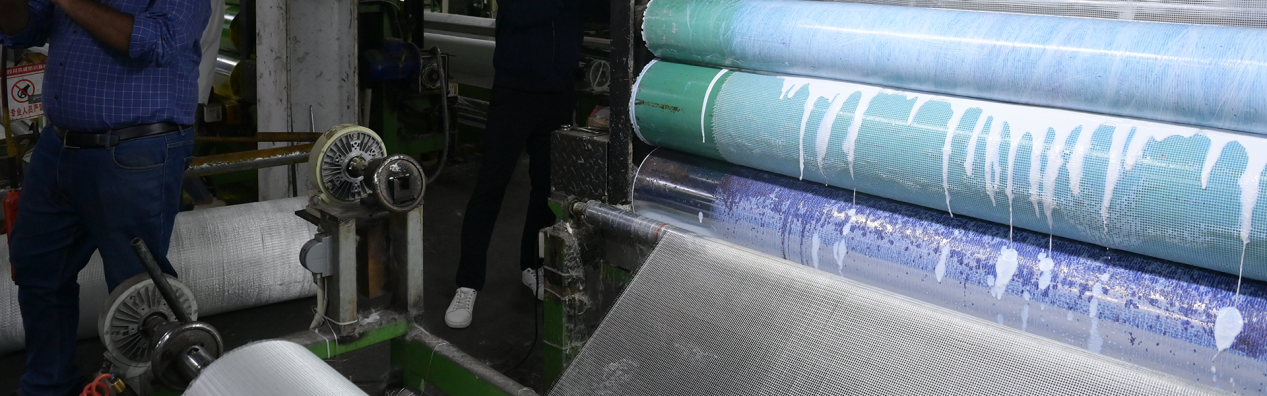

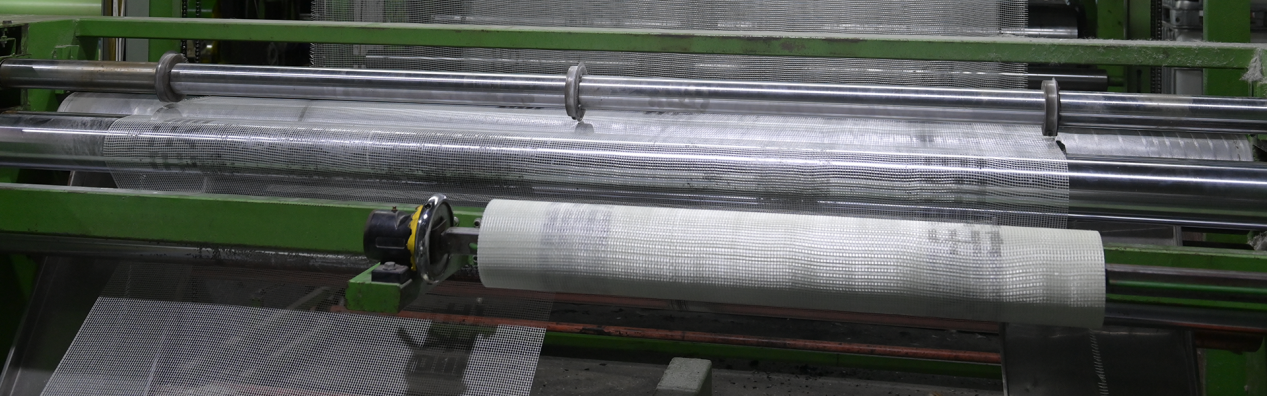

Fiberglass mesh is made from woven fiberglass yarn coated with alkali-resistant (AR) material, making it ideal for plastering, stucco, and exterior insulation systems. Key characteristics include:

High Tensile Strength – Resists cracking under stress.

Alkali Resistance – Essential for cement-based applications.

Flexibility – Adapts to curved surfaces without breaking.

Weather Resistance – Withstands extreme temperatures and UV exposure.

Choosing the right mesh depends on factors like material composition, weight, weave type, and coating quality.

2. Factors to Consider When Choosing Fiberglass Mesh

2.1. Material Composition & Alkali Resistance

Standard vs. AR (Alkali-Resistant) Mesh:

Standard fiberglass mesh degrades in cement-based environments.

AR-coated mesh is essential for plaster and stucco applications.

Check the Coating: High-quality fiberglass mesh uses acrylic or latex-based coatings for better durability.

2.2. Mesh Weight & Density

Measured in grams per square meter (g/m²).

Lightweight (50-100 g/m²): Suitable for thin plaster layers.

Medium (100-160 g/m²): Common for exterior wall insulation.

Heavy-duty (160+ g/m²): Used in high-stress areas like floors and roads.

2.3. Weave Type & Strength

Open Weave (4x4mm, 5x5mm): Allows better plaster adhesion.

Tighter Weave (2x2mm): Provides higher crack resistance.

Reinforced Edges: Prevents fraying during installation

2.4. Tensile Strength & Elongation

Tensile Strength (Warp & Weft): Should be ≥1000 N/5cm for construction use.

Elongation at Break: Should be ≤5% to prevent excessive stretching.

2.5. Manufacturer Reputation & Certifications

Look for ISO 9001, CE, or ASTM certifications.

Trusted brands include Saint-Gobain, Owens Corning, and China Fiberglass Mesh manufacturers with proven track records.

3. Common Mistakes When Buying Fiberglass Mesh

Choosing Based on Price Alone – Cheap mesh may lack alkali resistance, leading to premature failure.

Ignoring Weight & Density – Using lightweight fiberglass mesh for heavy-duty applications causes cracks.

Skipping UV Resistance Checks – Critical for exterior applications.

Not Testing Before Purchase – Always request samples to verify quality.

4. Applications of High-Quality Fiberglass Mesh

Exterior Insulation Finishing Systems (EIFS) – Prevents cracks in thermal insulation layers.

Drywall & Plaster Reinforcement – Reduces wall cracking over time.

Waterproofing Systems – Used in basements and bathrooms.

Road & Pavement Reinforcement – Enhances asphalt durability.

5. How to Test Fiberglass Mesh Quality

Alkali Resistance Test – Soak in NaOH solution; high-quality fiberglass mesh should remain intact.

Tensile Strength Test – Use a dynamometer to check load-bearing capacity.

Burn Test – Real fiberglass won’t melt like plastic-based fakes.

Flexibility Test – Should bend without breaking.

6. Future Trends in Fiberglass Mesh Technology

Self-Adhesive Mesh – Easier installation for DIY projects.

Eco-Friendly Options – Recycled fiberglass for sustainable construction.

Smart Mesh with Sensors – Detects structural stress in real time.

Conclusion

Selecting the best fiberglass mesh requires attention to material quality, weight, weave type, and certifications. Investing in high-AR-coated, heavy-duty mesh ensures long-term durability and crack prevention. Always buy from reputable suppliers and perform quality tests before large-scale use.

By following this guide, contractors, builders, and DIY enthusiasts can make informed decisions, ensuring stronger, crack-resistant structures for years to come.

Post time: May-06-2025