Introduction

As the demand for renewable energy grows, wind power continues to be a leading solution for sustainable electricity generation. A crucial part of wind turbines is that the blade, that should be light-weight, durable, and immune to environmental stressors. Fiberglass roving has emerged as a key material in turbine blade producing thanks to its superior strength-to-weight magnitude relation, corrosion resistance, and cost-effectiveness.

This article explores the key blessings of fiberglass roving in turbine blades, highlight why it remains a most popular alternative for makers and the way it contributes to the potency and longevity of wind energy systems.

1. High Strength-to-Weight Ratio Enhances Performance

One of the most significant benefits of fiberglass roving is its exceptional strength-to-weight ratio. Wind turbine blades must be lightweight to reduce the load on the turbine structure while maintaining high tensile strength to withstand aerodynamic forces.

Fiberglass roving provides excellent mechanical strength, allowing blades to endure high wind speeds without deformation.

Compared to traditional materials like steel, fiberglass reduces blade weight, improving energy efficiency and reducing wear on turbine components.

The lightweight nature of fiberglass enables longer blade designs, capturing more wind energy and increasing power output.

By optimizing the balance between weight and strength, fiberglass roving helps maximize turbine performance while minimizing structural stress.

2. Superior Fatigue Resistance for Longevity

Wind turbine blades are subjected to constant cyclic loading due to varying wind speeds and directional changes. Over time, this can lead to material fatigue and structural failure if not properly addressed.

Fiberglass roving exhibits high fatigue resistance, meaning it can endure millions of stress cycles without significant degradation.

Unlike metals, which can develop micro-cracks over time, fiberglass maintains its integrity under repetitive bending and torsional forces.

This sturdiness extends the time period of turbine blades, reducing maintenance prices and time period.

The ability of fiberglass to resist fatigue ensures long-term reliability, making it a cost-effective solution for wind energy applications.

3. Corrosion and Environmental Resistance

Wind turbines are exposed to harsh environmental conditions, including moisture, UV radiation, saltwater (in offshore installations), and temperature fluctuations. Traditional materials like steel are prone to corrosion, requiring frequent maintenance.

Fiberglass roving is inherently corrosion-resistant, making it ideal for both onshore and offshore wind farms.

It does not rust or degrade when exposed to water, humidity, or salt spray, unlike metal alternatives.

UV-resistant coatings can further enhance fiberglass’s ability to withstand prolonged sun exposure.

This resistance to environmental factors ensures that fiberglass-reinforced blades remain functional and efficient over decades, even in aggressive climates.

4. Cost-Effectiveness and Manufacturing Efficiency

Producing wind turbine blades requires materials that are not only strong and durable but also cost-effective to manufacture at scale.

Fiberglass roving is more affordable than carbon fiber while offering comparable performance for many applications.

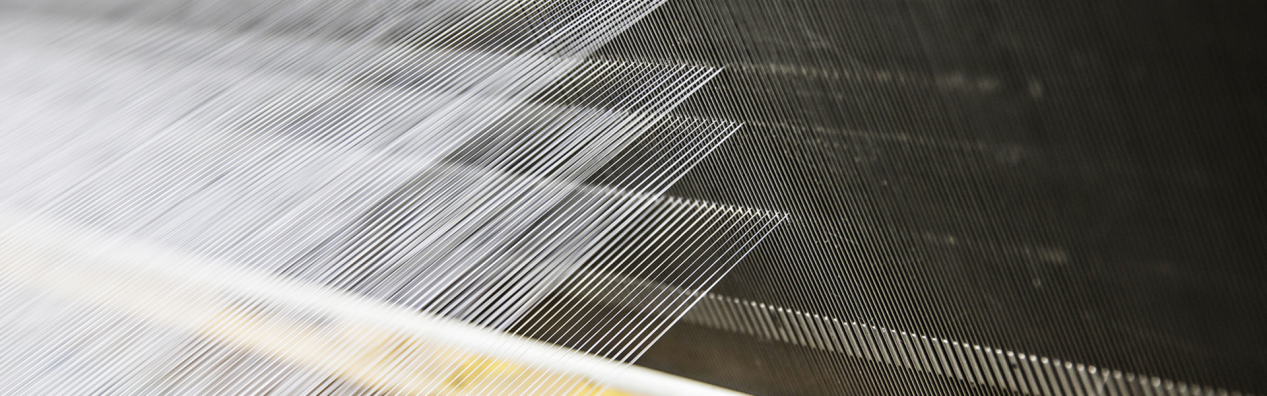

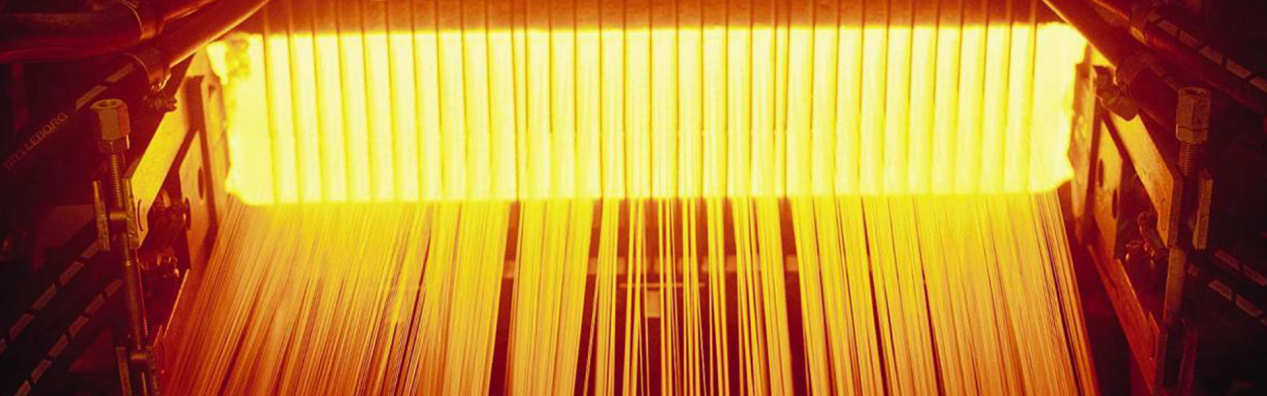

The material is easy to handle during the manufacturing process, allowing for faster production of composite blades using techniques like filament winding and pultrusion.

Its flexibility in design enables manufacturers to optimize blade shapes for better aerodynamics without excessive material waste.

By lowering production costs and improving manufacturing efficiency, fiberglass roving helps make wind energy more economically viable.

5. Design Flexibility for Optimized Aerodynamics

The aerodynamic efficiency of wind turbine blades directly impacts energy output. Fiberglass roving allows for greater design flexibility, enabling engineers to create blades with optimal shapes for maximum wind capture.

Fiberglass composites can be molded into complex geometries, including curved and tapered designs, which improve lift and reduce drag.

The material’s adaptability supports innovations in blade length and structure, contributing to higher energy yields.

Customizable fiber orientations enhance stiffness and load distribution, preventing premature failure.

This design versatility ensures that fiberglass-reinforced blades can be tailored to specific wind conditions, improving overall turbine efficiency.

6. Sustainability and Recyclability

As the wind energy industry grows, sustainability in material selection becomes increasingly important. Fiberglass roving offers environmental benefits compared to non-renewable alternatives.

Fiberglass production consumes less energy than metals like steel or aluminum, reducing the carbon footprint of blade manufacturing.

Advances in recycling technologies are making fiberglass composites more sustainable, with methods to repurpose end-of-life blades into new materials.

By extending blade lifespan, fiberglass reduces the frequency of replacements, minimizing waste.

These eco-friendly attributes align with the renewable energy sector’s commitment to sustainability.

Conclusion

Fiberglass roving plays a pivotal role in the performance, durability, and cost-efficiency of wind turbine blades. Its high strength-to-weight quantitative relation, fatigue resistance, corrosion protection, and style flexibility make it an important material within the wind energy trade.

As wind turbines continue to grow in size and capacity, the demand for advanced composite materials like fiberglass roving will only increase. By leveraging its key advantages, manufacturers can produce longer-lasting, more efficient blades, driving the future of sustainable energy.

For wind farm developers and turbine manufacturers, investing in high-quality fiberglass roving ensures reliable, high-performance blades that maximize energy output while minimizing operational costs.

Post time: May-06-2025