Introduction

With a global focus on sustainable energy options, there is a growing need for materials that improve both the efficiency and longevity of renewable energy systems. Renowned for its remarkable thermal resistance, electrical insulation, and mechanical strength, quartz fiber fabric plays a vital part in transforming technologies for solar and wind energy. This article examines the role of quartz fiber fabric in renewable energy applications, its advantages, and upcoming trends within the sector.

Why Quartz Fiber Fabric is Perfect for Renewable Energy

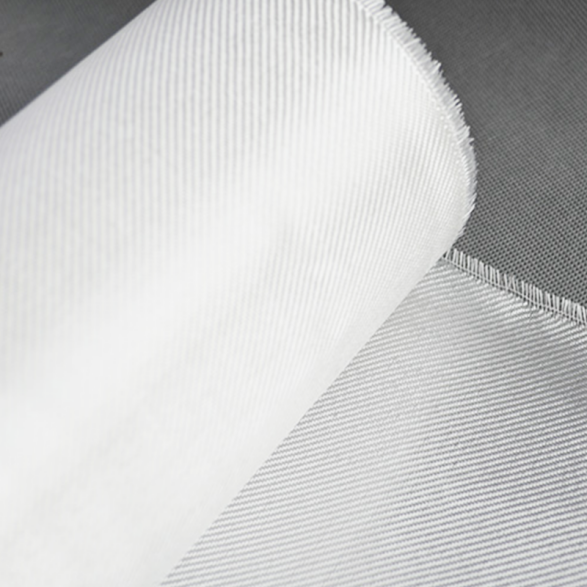

Quartz fiber fabric is made from high-purity silica, offering unique properties that make it valuable in extreme environments:

--High-temperature resistance (up to 1,050°C / 1,922°F)

--Excellent electrical insulation

--Low thermal conductivity

--Chemical and corrosion resistance

--Lightweight yet strong

These characteristics make it an ideal material for solar panels, wind turbine components, and energy storage systems, where reliability under harsh conditions is critical.

Quartz Fiber Fabric in Solar Energy Applications

1. Solar Panel Encapsulation and Backsheets

Solar panels are exposed to extreme weather, UV radiation, and temperature fluctuations. Quartz fiber fabric is used in:

--Backsheet reinforcement to improve durability and prevent moisture ingress.

--Encapsulation layers to protect photovoltaic cells from thermal stress.

2. Concentrated Solar Power (CSP) Systems

CSP plants use mirrors to focus sunlight, generating intense heat. Quartz fiber fabric is used in:

--Thermal insulation blankets to minimize heat loss.

--Receiver tube wraps to maintain high thermal efficiency.

3. Flexible Solar Panels

Emerging thin-film and flexible solar technologies benefit from quartz fiber’s lightweight and bendable nature, enabling innovative designs for portable and rooftop applications.

Quartz Fiber Fabric in Wind Energy Applications

1. Wind Turbine Blade Reinforcement

Wind turbine blades must withstand high mechanical stress and environmental wear. Quartz fiber fabric enhances:

--Stiffness and fatigue resistance, extending blade lifespan.

--Lightweighting, allowing for longer blades that capture more wind energy.

2. Generator and Transformer Insulation

The electrical components in wind turbines require materials that prevent short circuits and overheating. Quartz fiber fabric provides:

--High dielectric strength for generator insulation.

--Thermal protection in power transformers.

3. Nacelle and Hub Protection

The nacelle houses critical turbine machinery. Quartz fiber fabric is used in:

--Fireproof barriers to prevent electrical fires.

--Vibration damping layers to reduce mechanical wear.

Future Trends: Quartz Fiber Fabric in Next-Gen Renewable Energy

1. Integration with Energy Storage Systems

As battery technologies evolve, quartz fiber fabric could be used in:

--Thermal management for lithium-ion batteries.

--Fireproof barriers in grid-scale energy storage.

2. Smart Textiles for Solar-Wind Hybrid Systems

Researchers are exploring quartz fiber-based smart textiles that can:

--Monitor structural health of wind turbines and solar farms.

--Self-heal minor damages using embedded nanomaterials.

3. Sustainable Manufacturing Advances

Efforts are underway to reduce the carbon footprint of quartz fiber production, making it even more eco-friendly for renewable energy applications.

Conclusion

Quartz fiber fabric is proving to be a game-changer in renewable energy, enhancing the efficiency, durability, and safety of solar and wind power systems. As the demand for clean energy grows, innovations in quartz fiber technology will further solidify its role in a sustainable future.

For industries looking to improve their renewable energy solutions, investing in high-performance quartz fiber fabric is a forward-thinking choice.

Post time: Jun-11-2025