In the vast world of synthetic polymers, the term “polyester” is ubiquitous. However, it’s not a single material but a family of polymers with vastly different characteristics. For engineers, manufacturers, designers, and DIY enthusiasts, understanding the fundamental divide between saturated polyester and unsaturated polyester is crucial. This isn’t just academic chemistry; it’s the difference between a durable water bottle, a sleek sports car body, a vibrant fabric, and a sturdy boat hull.

This comprehensive guide will demystify these two polymer types. We’ll delve into their chemical structures, explore their defining properties, and illuminate their most common applications. By the end, you’ll be able to distinguish between them with confidence and understand which material is right for your specific needs.

At a Glance: The Core Difference

The single most important difference lies in their molecular backbone and how they are cured (hardened into a final solid form).

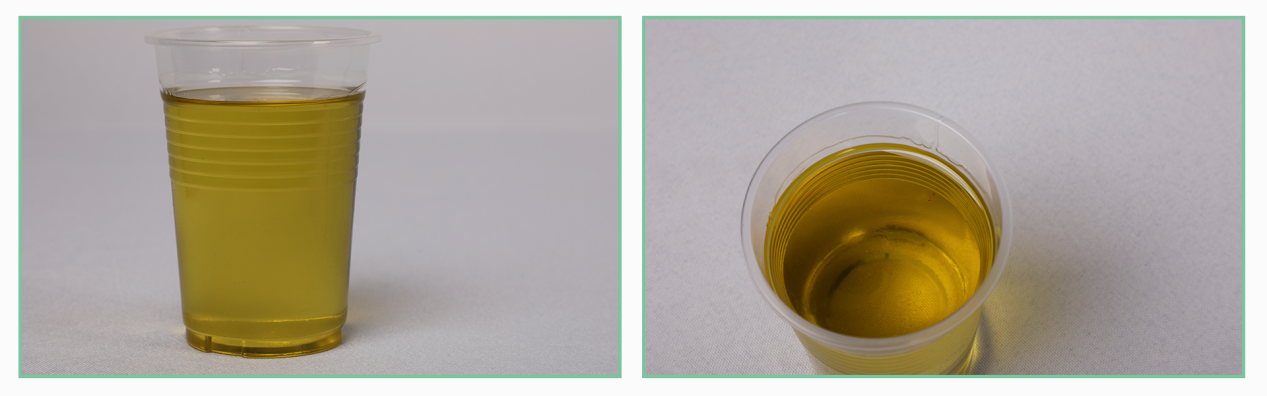

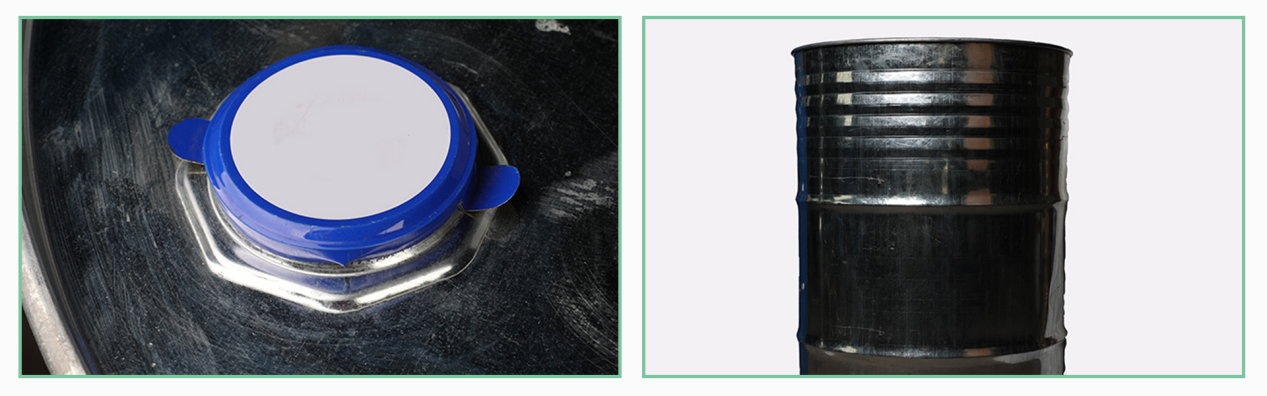

·Unsaturated Polyester (UPE): Features reactive double bonds (C=C) in its backbone. It is typically a liquid resin that requires a reactive monomer (like styrene) and a catalyst to cure into a rigid, cross-linked, thermosetting plastic. Think Fiberglass Reinforced Plastic (FRP).

·Saturated Polyester: Lacks these reactive double bonds; its chain is “saturated” with hydrogen atoms. It is typically a solid thermoplastic that softens when heated and hardens when cooled, allowing for recycling and remolding. Think PET bottles or polyester fibers for clothing.

The presence or absence of these carbon double bonds dictates everything from processing methods to final material properties.

Deep Dive into Unsaturated Polyester (UPE)

Unsaturated polyesters are the workhorses of the thermosetting composite industry. They are created through a polycondensation reaction between diacids (or their anhydrides) and diols. The key is that a portion of the diacids used are unsaturated, such as maleic anhydride or fumaric acid, which introduce the critical carbon-carbon double bonds into the polymer chain.

Key Characteristics of UPE:

·Thermosetting: Once cured through cross-linking, they become AN infusible and insoluble 3D network. they can’t be remelted or reshaped; heating causes decomposition, not melting.

·Curing Process: Requires two key components:

- A Reactive Monomer: Styrene is most common. This monomer acts as a solvent to reduce the resin’s viscosity and, crucially, cross-links with the double bonds in the polyester chains during curing.

- A Catalyst/Initiator: Usually an organic peroxide (e.g., MEKP – Methyl Ethyl Ketone Peroxide). This compound decomposes to generate free radicals that initiate the cross-linking reaction.

·Reinforcement: UPE resins are rarely used alone. They are almost always reinforced with materials like fiberglass, carbon fiber, or mineral fillers to create composites with exceptional strength-to-weight ratios.

·Properties: Excellent mechanical strength, good chemical and weather resistance (especially with additives), good dimensional stability, and high heat resistance post-cure. They can be formulated for specific needs like flexibility, fire retardancy, or high corrosion resistance.

Common Applications of UPE:

·Marine Industry: Boat hulls, decks, and other components.

·Transportation: Car body panels, truck cabs, and RV parts.

·Construction: Building panels, roofing sheets, sanitary ware (bathtubs, shower stalls), and water tanks.

·Pipes and Tanks: For chemical processing plants due to corrosion resistance.

·Consumer Goods:

·Artificial Stone: Engineered quartz countertops.

Deep Dive into Saturated Polyester

Saturated polyesters are formed from a polycondensation reaction between saturated diacids (e.g., terephthalic acid or adipic acid) and saturated diols (e.g., ethylene glycol). With no double bonds in the backbone, the chains are linear and cannot cross-link with each other in the same way.

Key Characteristics of Saturated Polyester:

·Thermoplastic: They soften once heated and harden upon cooling. This process is reversible and allows for easy processing like injection molding and extrusion, and enables recycling.

·No External Curing Needed: They do not require a catalyst or reactive monomer to solidify. They solidify simply by cooling from a melt state.

·Types: This category includes several well-known engineering plastics:

PET (Polyethylene Terephthalate): The foremost common kind, used for fibers and packaging.

PBT (Polybutylene Terephthalate): A strong, stiff engineering plastic.

PC (Polycarbonate): Often grouped with polyesters due to similar properties, though its chemistry is slightly different (it’s a polyester of carbonic acid).

·Properties: Good mechanical strength, excellent toughness and impact resistance, good chemical resistance, and excellent processability. They are additionally familiar for his or her sensible electrical insulating properties.

Common Applications of Saturated Polyester:

·Textiles: The single largest application. Polyester fiber for clothing, carpets, and fabrics.

·Packaging: PET is the material for soft drink bottles, food containers, and packaging films.

·Electrical and Electronics: Connectors, switches, and housings due to good insulation and heat resistance (e.g., PBT).

·Automotive: Components like door handles, bumpers, and headlight housings.

·Consumer Goods:

·Medical Devices: Certain types of packaging and components.

Head-to-Head Comparison Table

|

Feature |

Unsaturated Polyester (UPE) |

Saturated Polyester (e.g., PET, PBT) |

|

Chemical Structure |

Contains reactive C=C double bonds in backbone |

No C=C double bonds; chain is saturated |

|

Polymer Type |

Thermoset |

Thermoplastic |

|

Curing/Processing |

Cured with peroxide catalyst & styrene monomer |

Processed by heating & cooling (molding, extrusion) |

|

Re-moldable/Recyclable |

No, cannot be remelted |

Yes, can be recycled and remolded |

|

Typical Form |

Liquid resin (pre-cure) |

Solid pellets or chips (pre-process) |

|

Reinforcement |

Almost always used with fibers (e.g., fiberglass) |

Often used neat, but can be filled or reinforced |

|

Key Properties |

High strength, rigid, heat resistant, corrosion resistant |

Tough, impact-resistant, good chemical resistance |

|

Primary Applications |

Boats, car parts, bathtubs, countertops |

Bottles, clothing fibers, electrical components |

Why the Distinction Matters for Industry and Consumers

Choosing the wrong type of polyester can lead to product failure, increased costs, and safety issues.

·For a Design Engineer: If you need a large, strong, lightweight, and heat-resistant part like a boat hull, you must choose a thermosetting UPE composite. Its ability to be hand-laid into a mold and cured at room temperature is a key advantage for large objects. If you need millions of identical, high-precision, recyclable components like electrical connectors, a thermoplastic like PBT is the clear choice for high-volume injection molding.

·For a Sustainability Manager: The recyclability of saturated polyesters (especially PET) is a major advantage. PET bottles can be efficiently collected and recycled into new bottles or fibers (rPET). UPE, as a thermoset, is notoriously difficult to recycle. End-of-life UPE products often end up in landfills or must be incinerated, though mechanical grinding (for use as filler) and chemical recycling methods are emerging.

·For a Consumer: When you buy a polyester shirt, you are interacting with a saturated polyester. When you step into a fiberglass shower unit, you are touching a product made from unsaturated polyester. Understanding this difference explains why your water bottle can be melted and recycled, while your kayak cannot.

The Future of Polyesters: Innovation and Sustainability

The evolution of both saturated and unsaturated polyesters continues at a rapid pace.

·Bio-based Feedstocks: Research is focused on creating both UPE and saturated polyesters from renewable resources like plant-based glycols and acids to reduce reliance on fossil fuels.

·Recycling Technologies: For UPE, significant effort is going into developing viable chemical recycling processes to break down cross-linked polymers into reusable monomers. For saturated polyesters, advancements in mechanical and chemical recycling are improving efficiency and the quality of recycled content.

·Advanced Composites: UPE formulations are constantly being improved for better fire retardancy, UV resistance, and mechanical properties to meet stricter industry standards.

·High-Performance Thermoplastics: New grades of saturated polyesters and co-polyesters are being developed with enhanced heat resistance, clarity, and barrier properties for advanced packaging and engineering applications.

Conclusion: Two Families, One Name

While they share a common name, saturated and unsaturated polyesters are distinct material families serving different worlds. Unsaturated polyester (UPE) is the thermosetting champion of high-strength, corrosion-resistant composites, forming the backbone of industries from marine to construction. Saturated polyester is the versatile thermoplastic king of packaging and textiles, prized for its toughness, clarity, and recyclability.

The difference boils down to a simple chemical feature—the carbon double bond—but the implications for manufacturing, application, and end-of-life are profound. By understanding this critical distinction, manufacturers can make smarter material choices, and consumers can better understand the complex world of polymers that shapes our modern lives.

Contact us:

Telephone number: +86 023-67853804

WhatsApp:+86 15823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Oct-10-2025