In the world of composite manufacturing, significant resources are spent optimizing resin chemistry, perfecting pultrusion speeds, and refining fiber-to-resin ratios. However, a critical factor is often overlooked until a production line grinds to a halt or a batch of finished parts fails a stress test: the storage environment of the fiberglass roving.

Fiberglass roving is not an inert commodity. It is a highly engineered material coated with a complex chemical “sizing” that serves as the interface between the inorganic glass and the organic resin. This chemistry is sensitive, and its degradation during storage can lead to catastrophic failures in structural integrity.

In this guide, we examine how temperature, humidity, and physical storage practices dictate the performance of your reinforcement materials.

The Invisible Enemy: Humidity and Hydrolysis

The most significant threat to stored fiberglass roving is moisture. Glass fiber is naturally hydrophilic (water-attracting). While the glass filaments themselves are durable, the sizing system—the chemical bridge that allows the resin to “wet out” and bond to the fiber—is susceptible to hydrolysis.

When glass fiber roving is stored in a high-humidity environment:

Sizing Degradation: Moisture breaks the chemical bonds within the sizing, rendering it less effective at promoting adhesion.

Poor Wet-Out: During production, the resin fails to penetrate the fiber bundle completely, leading to “dry spots” and voids in the final composite.

Capillary Action: If the ends of the bobbins are exposed, moisture can be drawn deep into the package through capillary action, causing inconsistent performance throughout the entire roll.

Temperature Fluctuations and Sizing Migration

While glass fiber has high thermal resistance, the organic sizing does not. If a warehouse is subjected to extreme heat (above 35°C/95°F), a phenomenon known as sizing migration can occur. The chemical coating can become slightly mobile, pooling at the bottom of the bobbin or creating “sticky spots.”

Conversely, storing roving in freezing conditions and then immediately moving it to a warm production floor leads to condensation. This rapid moisture accumulation on the fiber surface is a leading cause of delamination in filament-wound pipes and pressure vessels.

Comparison: Optimal vs. Substandard Storage Conditions

To help your quality control team audit your facilities, refer to the following table for industry-standard benchmarks.

Fiberglass Roving Storage Standards

|

Parameter |

Optimal Condition (Best Practice) |

Substandard Condition (High Risk) |

Impact on Performance |

|

Temperature |

5°C to 35°C (Stable) |

Below 0°C or Above 40°C |

Sizing migration, brittle fibers, or condensation. |

|

Relative Humidity |

35% to 65% |

Above 75% |

Hydrolysis of sizing, poor resin-to-fiber bond. |

|

Acclimatization |

24–48 hours in the workshop before use. |

Direct use from cold storage. |

Micro-cracks in the resin matrix due to moisture. |

|

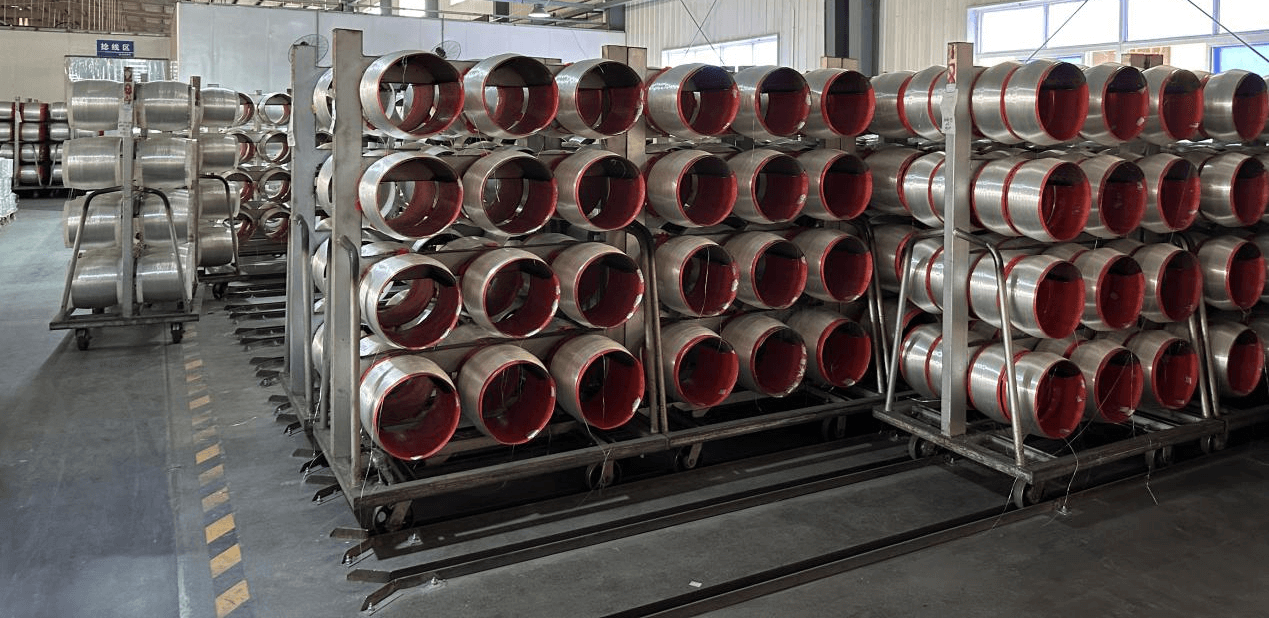

Stacking |

Original pallets; maximum 2 high (if designed). |

Loose bobbins; excessive stacking height. |

Physical deformation of bobbins; tension issues. |

|

Light Exposure |

Dark or low UV environment. |

Direct sunlight (near windows). |

UV degradation of packaging and sizing chemicals. |

Physical Integrity: Stacking and Tension Issues

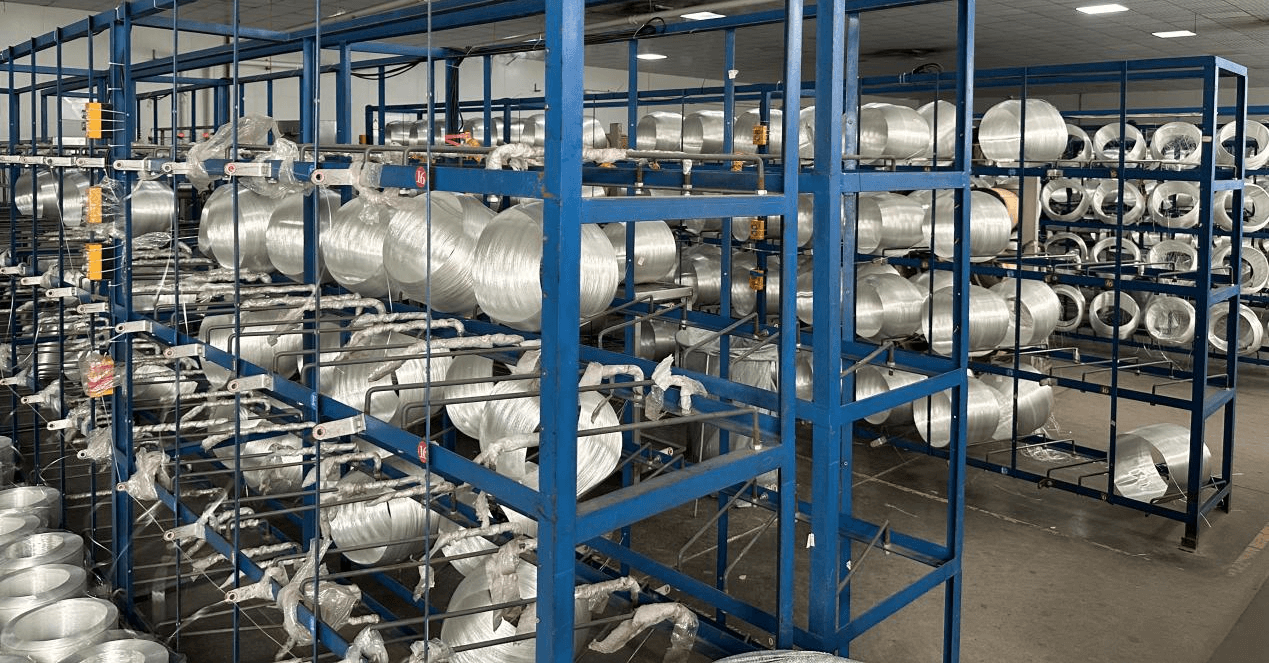

Fiberglass roving is typically wound onto bobbins with precise tension. If these bobbins are stored improperly—such as being stacked horizontally without support or being crushed under excessive weight—the internal geometry of the package changes.

Tension Variations: Crushed bobbins lead to uneven “pay-off” during pultrusion or filament winding. This results in some fibers being tighter than others, creating internal stresses in the finished part that can lead to warping or premature failure.

Fuzz and Breakage: When bobbins are bumped or dragged across rough warehouse floors, the outer layers of the glass are damaged. These broken filaments create “fuzz” in the production line, which can clog guides and contaminate the resin bath.

The Role of Packaging: Why “Original” is Best

High-quality fiberglass roving is usually delivered in UV-stabilized shrink wrap with desiccant packs. A common mistake in manufacturing facilities is stripping this packaging prematurely.

The original wrap serves three vital functions:

Moisture Barrier: It acts as a primary shield against ambient humidity.

Dust Prevention: Particulate matter (dust, sawdust, or metallic shavings) from a factory environment can interfere with the chemical bond between the glass and resin.

Containment: It prevents the roving from “sloughing” or falling off the bobbin during handling.

5 Best Practices for Maintaining Roving Quality

To ensure your material performs exactly as specified by the manufacturer, implement these five warehouse protocols:

First-In, First-Out (FIFO): Fiberglass roving has a shelf life, typically 6 to 12 months. Ensure older stock is used first to prevent aging of the sizing.

The 24-Hour Rule: Always bring roving from the warehouse into the production hall at least 24 hours before use. This allows the material to reach “thermal equilibrium,” preventing condensation when the package is opened.

Elevated Storage: Never store pallets of roving directly on a concrete floor, which can “wick” moisture. Use racking or wooden pallets.

Seal Partial Bobbins: If a bobbin is only half-used, do not leave it exposed on the machine. Re-wrap it in plastic before returning it to storage.

Monitor with Hygrometers: Install digital temperature and humidity monitors in your storage areas. This data is invaluable when troubleshooting a sudden spike in production defects.

Conclusion: Protecting Your Investment

Fiberglass roving is a high-performance material, but its performance is fragile until it is cured within a resin matrix. By treating storage conditions with the same level of scrutiny as your manufacturing parameters, you can significantly reduce scrap rates, improve part consistency, and ensure the long-term durability of your composite products.

Chongqing Dujiang Composites Co., Ltd.

Contact Us:

Web: www.frp-cqdj.com / www.cqfiberglass.com/www.cqfrp.ru / www.cqdjfrp.com

Email: info@cqfiberglass.com / marketing@frp-cqdj.com /marketing01@frp-cqdj.com

WhatsApp: +8615823184699

Tel:+86-023-67853804

Post time: Jan-09-2026