In the world of advanced materials, where extreme conditions demand exceptional performance, one substance stands out for its unparalleled purity and resilience: quartz fiber. You may have encountered it in the sleek nose cone of a spacecraft or felt its influence in the reliable operation of your smartphone. But what exactly is quartz fiber, and what does it do that makes it so indispensable across such a diverse range of high-tech industries?

This deep dive explores the remarkable capabilities of quartz fiber and why it is the material of choice where failure is not an option.

The Foundation: What is Quartz Fiber?

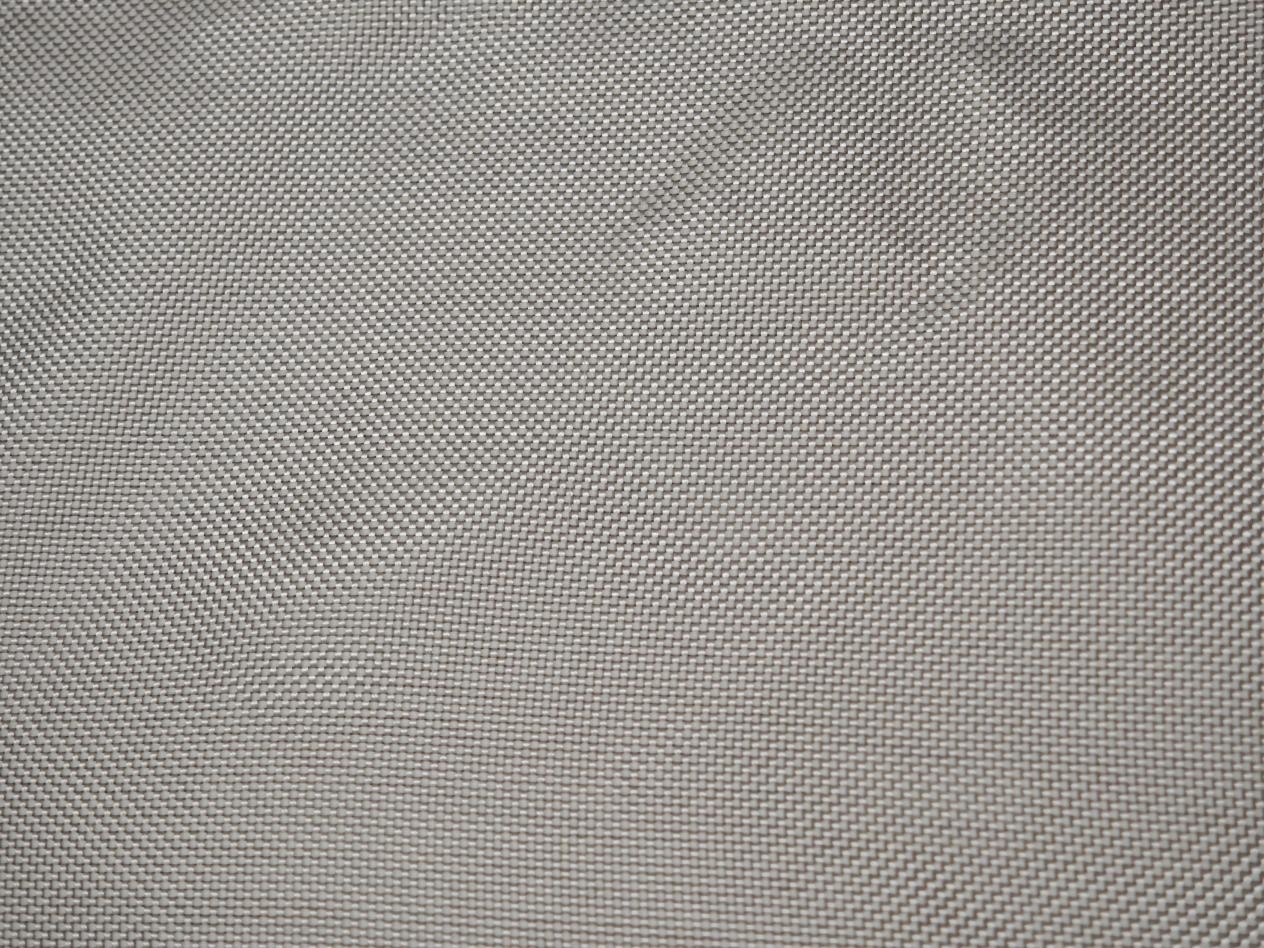

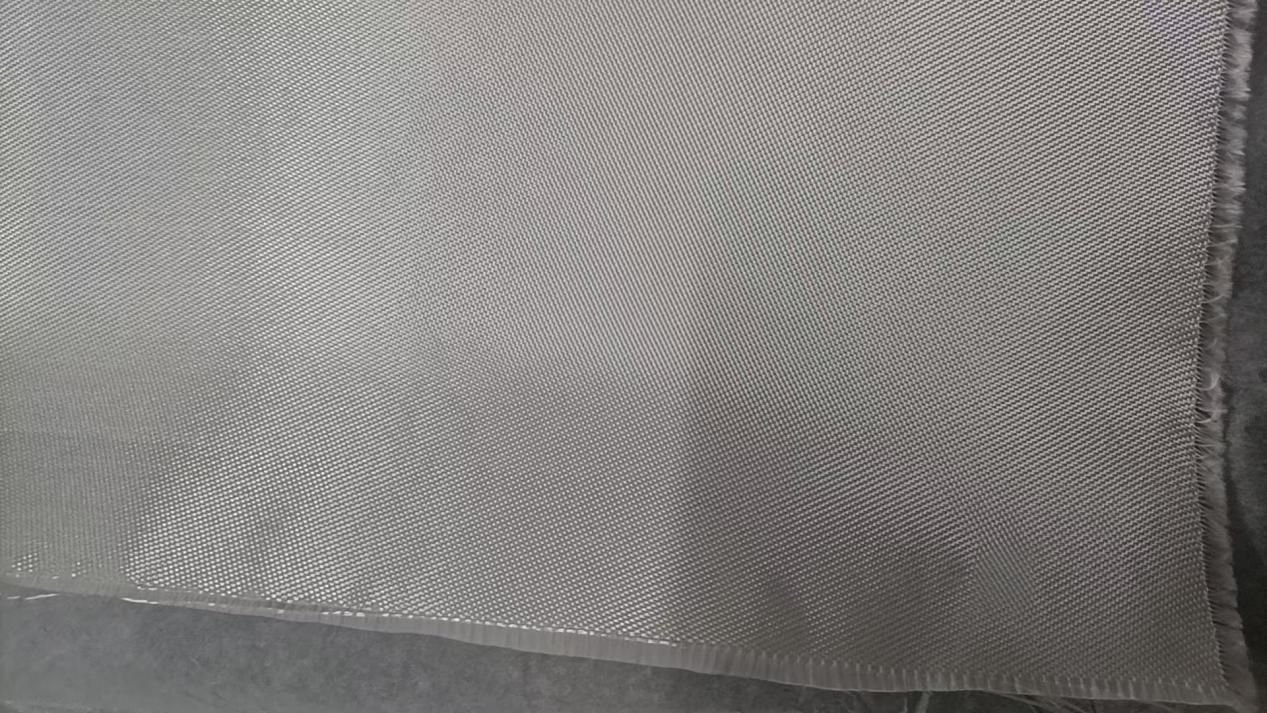

At its core, quartz fiber is a material made from high-purity silica (SiO₂), typically exceeding 99.95%. Unlike traditional glass fibers which are made from various oxides, quartz fiber’s exceptional properties stem from this extreme purity and its unique molecular structure. It can be spun into filaments, yarns, fabrics, and bats, offering engineers and designers a versatile material to solve complex thermal and electrical challenges.

Think of it as the ultimate high-performance version of fiberglass. While they may look similar, their performance gap, especially in high-temperature environments, is astronomical.

The Multifaceted Superpowers of Quartz Fiber: What Does It Do?

Quartz fiber isn’t a one-trick pony. Its value lies in a combination of properties that are difficult to find in any other single material. Here’s a breakdown of its core functions:

1.It Withstands Extreme Heat Like a Champion

This is its most celebrated ability. Quartz fiber has an exceptionally high melting point of over 1700°C (3092°F). But more importantly, it exhibits low thermal conductivity, meaning it doesn’t easily transfer heat.

What it does in practice:

–Thermal Protection: It acts as a critical insulating barrier in aerospace and aviation, used in thermal protection systems (TPS) for spacecraft re-entry vehicles, rocket engine nozzles, and heat shields for satellites. It keeps the intense heat out, protecting sensitive components and structures.

–Industrial Furnaces: It is used as insulation and conveyor belts in high-temperature industrial furnaces for glass manufacturing, metal heat treatment, and semiconductor processing, where it maintains structural integrity for far longer than alternatives.

2. It Manages Thermal Shock with Ease

Many materials can handle gradual heating, but sudden, drastic temperature changes cause them to crack and shatter. Quartz fiber has an extremely low coefficient of thermal expansion. It barely expands when heated and contracts when cooled.

What it does in practice:

This property makes it virtually immune to thermal shock. A component made from quartz fiber can be taken from a freezing environment and plunged directly into a high-temperature furnace without cracking. This is critical for applications like rapid-heat treatment chambers and laboratory equipment.

3. It Provides Excellent Electrical Insulation

Even at high temperatures and high frequencies, quartz fiber remains an excellent electrical insulator. Its pure silica composition does not readily conduct electricity.

What it does in practice:

–Electronics and Semiconductor: It is used as a substrate for circuit boards in high-frequency applications and as insulating parts in semiconductor manufacturing equipment.

–Aerospace and Defense: It ensures electrical systems are protected from short circuits and interference in demanding environments, from radar systems to avionics bays.

4. It Possesses Superior Dielectric Properties

Related to insulation, quartz fiber has a very low dielectric constant and loss tangent. This means that when used in electronic applications, it minimally interferes with the transmission of electromagnetic signals.

What it does in practice:

This makes it a premium material for radomes—the protective domes that cover radar antennas on aircraft, ships, and ground stations. The radome must be structurally strong and thermally resistant while being “transparent” to radar waves; quartz fiber is one of the few materials that can meet all these demands simultaneously.

5. It is Chemically Resistant and Dimensionally Stable

Quartz fiber offers high resistance to corrosion from many acids and solvents. Furthermore, its low thermal expansion means it does not warp or change shape significantly under thermal cycling.

What it does in practice:

It is used in chemical processing environments as gaskets, seals, and insulation for aggressive media.

Its dimensional stability is crucial for composite tooling. Molds made with quartz fiber fabric are used to cure carbon fiber parts in autoclaves because they can withstand the high pressure and temperature cycles without deforming, ensuring the final part’s precise geometry.

Real-World Applications: Where You Find Quartz Fiber in Action

–Aerospace & Defense: Thermal blankets for satellites, missile nose cones, radomes, rocket engine insulation, firewalls in aircraft.

–Semiconductor Industry: Diffusion furnace insulation, wafer carriers, process tube supports.

–Electronics: High-frequency circuit board substrates.

–Industrial Processing: High-temperature conveyor belts, furnace curtains, welding protection.

–Fire Protection: Critical insulation in high-performance fire barriers and safety equipment.

Why Source Your Quartz Fiber from a Trusted Manufacturer?

The performance of quartz fiber is directly tied to its purity and manufacturing quality. Impurities can drastically reduce its thermal stability and dielectric properties. A reliable manufacturer ensures:

Consistent Purity: Guaranteeing the material performs as expected in extreme conditions.

Fabric Integrity: Weaving that is uniform and free of defects that could become failure points.

Technical Expertise: Providing not just a product, but the application support to help you integrate it effectively into your design.

Empower Your Most Demanding Applications with Our Quartz Fiber Solutions

At CQDJ, we don’t just supply quartz fiber; we provide a foundational material for innovation. Our high-purity quartz fiber cloth and fabrics are engineered to deliver unmatched reliability, thermal management, and electrical performance.

If your projects are pushing the boundaries of temperature, performance, and reliability, you need a material partner that can keep up.

Explore our comprehensive range of high-performance materials, including quartz fiber cloth, fiberglass, and complementary resins, to find your complete process solution.

Post time: Nov-07-2025