The marine business is one of the foremost stringent environments for materials, requiring sturdiness, resistance to harsh conditions, and long-run performance. Among the varied materials employed in marine applications, fibreglass cloth has emerged as a high alternative for boat builders, repair specialists, and marine engineers. Its distinctive properties make it an imperative material for constructing and maintaining vessels that stand up to the challenges of seawater, actinic ray exposure, and mechanical stress. During this article, we tend to explore why fibreglass cloth is the go-to material for marine applications and the way it continues to revolutionize the business.

What is Fiberglass Cloth?

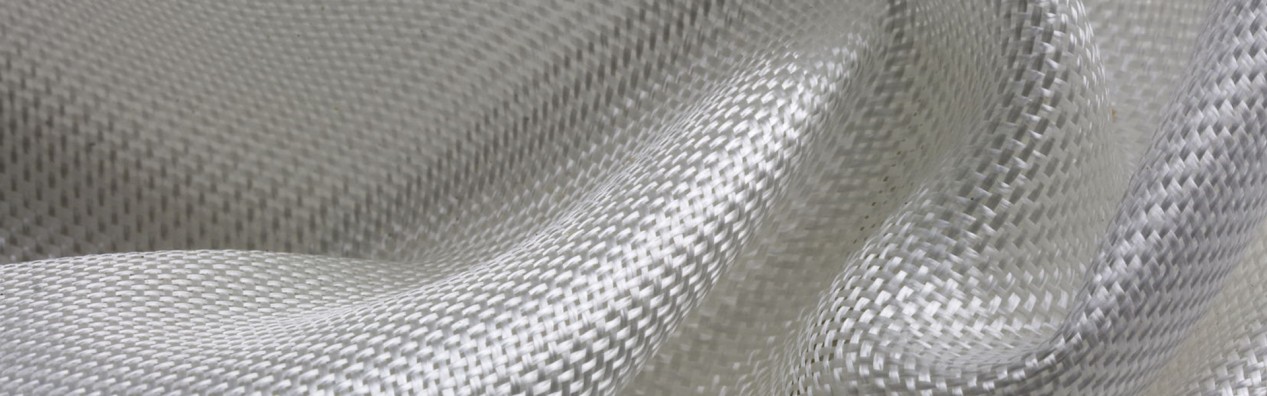

Fiberglass cloth is a woven fabric made from fine strands of glass fibers. These fibers are lightweight, strong, and resistant to corrosion, making them ideal for use in composite materials. When combined with resins, fiberglass cloth forms a durable and rigid structure that is widely used in industries such as construction, automotive, aerospace, and marine.

In marine applications, fiberglass cloth is typically used in the form of fiberglass-reinforced plastic (FRP) or as a standalone material for repairs and reinforcements. Its versatility and performance have made it a staple in boat building, hull repairs, and even in the creation of marine accessories like kayaks and paddleboards.

Key Properties of Fiberglass Cloth for Marine Use

1. Corrosion Resistance:

Unlike metals, fiberglass cloth does not rust or corrode when exposed to saltwater. This makes it an excellent choice for boat hulls, decks, and other components that are constantly in contact with seawater.

2. High Strength-to-Weight Ratio:

Fiberglass cloth is incredibly strong yet lightweight, which is crucial for marine applications. Boats and other marine vessels need to be buoyant and agile, and fiberglass helps achieve this without compromising on strength.

3. UV Resistance:

Marine environments expose materials to intense sunlight and UV radiation. Fiberglass cloth, especially when coated with UV-resistant resins, can withstand prolonged exposure without degrading.

4. Waterproof and Non-Absorbent:

Fiberglass cloth is inherently waterproof, making it ideal for marine use. It does not absorb water, which prevents issues like swelling, warping, or rotting that can occur with other materials.

5. Flexibility and Versatility:

Fiberglass cloth can be molded into complex shapes, making it perfect for custom boat designs and repairs. It can also be layered to increase thickness and strength, depending on the application.

Applications of Fiberglass Cloth in the Marine Industry

1. Boat Hulls and Decks:

Fiberglass cloth is widely used in the construction of boat hulls and decks. Its strength and durability ensure that the vessel can withstand the pressures of water and the impacts of waves.

2. Marine Repairs:

Fiberglass cloth is a popular choice for repairing damaged boat parts. Whether it’s a cracked hull or a worn-out deck, fiberglass cloth can be used to reinforce and restore the structure.

3. Kayaks and Canoes:

Lightweight and durable, fiberglass cloth is often used to build kayaks, canoes, and paddleboards. Its ability to resist water and UV damage ensures a long lifespan for these watercraft.

4. Marine Accessories:

From fishing rods to storage compartments, fiberglass cloth is used to create a variety of marine accessories that require strength and resistance to harsh conditions.

Advantages Over Traditional Materials

Fiberglass cloth has several advantages over traditional materials like wood and metal. Wood, while lightweight, is prone to rotting and requires constant maintenance. Metals, on the other hand, are heavy and susceptible to corrosion. Fiberglass cloth offers the best of both worlds: it is lightweight, durable, and requires minimal maintenance.

Environmental Benefits

In addition to its performance benefits, fiberglass cloth is also an environmentally friendly option. It is long-lasting, reducing the need for frequent replacements, and can be recycled at the end of its life cycle. This makes it a sustainable choice for the marine industry, which is increasingly focused on reducing its environmental impact.

Future Trends in fiberglass cloth for Marine Applications

As technology advances, fiberglass cloth is changing into even additional economical and versatile. Innovations in organic compound formulations and weaving techniques square measure enhancing its strength, flexibility, and resistance to environmental factors. in addition, the event of eco-friendly resins is creating fiberglass cloth a fair additional property choice for marine applications.

Conclusion

Fiberglass cloth has attained its name because the go-to material for marine applications thanks to its unmatched combination of strength, durability, and resistance to harsh conditions. whether or not it’s for building new boats, repairing existing ones, or making marine accessories, fiberglass cloth continues to play a significant role within the marine trade. As technology evolves, we will expect fiberglass cloth to become even additional integral to marine applications, giving improved performance and property.

For boat builders, marine engineers, and DIY enthusiasts, fiberglass cloth could be a reliable and cost-efficient answer that ensures durable performance in even the foremost difficult environments. Its skillfulness and environmental edges create it a cloth that may stay at the forefront of marine innovation for years to return.

Post time: Jun-21-2025