Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

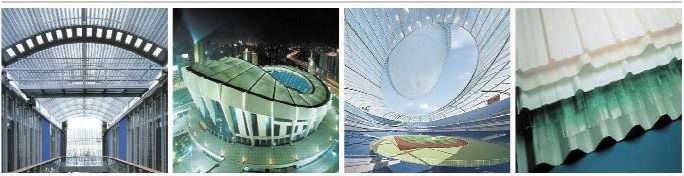

528S is mainly used to make transparent sheets and transparent felt sheets. The board has the characteristics of lightweight material, high strength, good impact resistance, no white silk, and high light transmittance.

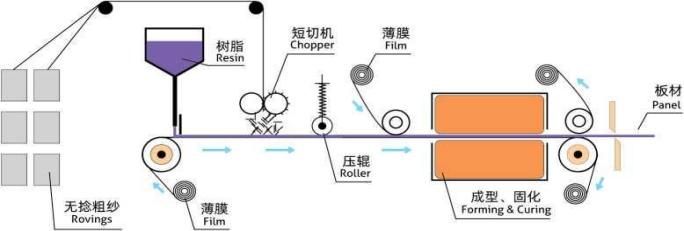

Continuous Panel Molding Process

resin mix is uniformly deposited in a controlled amount onto a moving film at aconstant speed. The thickness of the resin is controlled by the draw-knife. Fiberglass roving is chopped and uniformly distributed onto the resin. Then a top film is applied forming a sandwich structure. The wet assembly travels through a curing oven to form the composite panel.

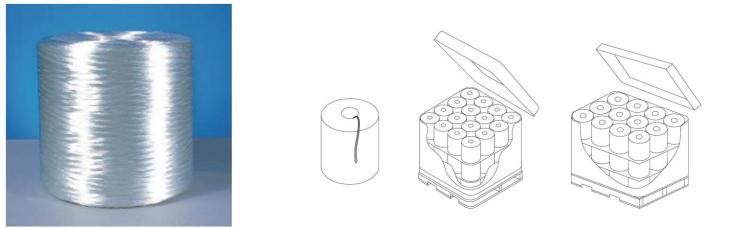

| Model | E3-2400-528s |

| Type of Size | Silane |

| Size Code | E3-2400-528s |

| Linear Density (tex) | 2400TEX |

| Filament Diameter (μm) | 13 |

| Linear Density (%) | Moisture Content | Size Content (%) | Breakage Strength |

| ISO 1889 | ISO3344 | ISO1887 | ISO3375 |

| ± 5 | ≤ 0.15 | 0.55 ± 0. 15 | 120 ± 20 |

(Building and Construction / Automotive /Agriculture/Fibreglass Reinforced Polyester)

• Unless otherwise specified, the fiberglass products should be stored in a dry,cool and moisture-proof area.

• The fiberglass products should remain in their original package until prior to use. The room temperature and humidity should be always maintained at – 10℃~35℃ and ≤80% respectively.

• To ensure safety and avoid damage to the product, the pallets should not be stacked more than three layers high.

• When the pallets are stacked in 2 or 3 layers, special care should be taken to correctly and smoothly move the top pallets

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.