PROPERTY

- Enhanced Durability: By resisting alkali and chemical attacks, AR fiberglass extends the life of reinforced structures.

- Weight Reduction: Provides reinforcement without adding significant weight, which is particularly beneficial for large-scale construction projects.

- Improved Workability: Easier to handle and install compared to traditional reinforcement materials like steel.

- Versatility: Suitable for a wide range of applications in construction, industrial, and marine environments.

APPLICATION

- Glass Fiber Reinforced Concrete (GFRC):

- AR fiberglass roving is extensively used in GFRC to enhance the strength and durability of concrete structures. It is used in the form of chopped strands, which are mixed with concrete to improve its crack resistance and mechanical properties.

- Precast Concrete Products:

- Precast components, such as panels, facades, and architectural elements, often use AR fiberglass for reinforcement to improve their longevity and reduce weight without compromising structural integrity.

- Construction and Infrastructure:

- It is used in reinforcing mortars, plasters, and other construction materials to improve their resistance to cracking and degradation, especially in environments where exposure to alkali or other chemicals is a concern.

- Pipeline and Tank Reinforcement:

- AR fiberglass roving is employed in the production of reinforced concrete pipes and tanks, providing resistance to chemical attack and mechanical reinforcement.

- Marine and Industrial Applications:

- The material’s resistance to corrosive environments makes it ideal for marine structures and industrial applications where exposure to aggressive chemicals is common.

IDENTIFICATION

| Example |

E6R12-2400-512 |

| Glass Type |

E6-Fiberglass assembled roving |

| Assembled Roving |

R |

| Filament Diameter μm |

12 |

| Linear Density, tex |

2400, 4800 |

| Size Code |

512 |

Considerations for Use:

- Cost: Although more expensive than conventional fiberglass, the benefits in terms of durability and longevity often justify the cost in critical applications.

- Compatibility: Ensuring compatibility with other materials, such as concrete, is crucial for optimal performance.

- Processing Conditions: Proper handling and processing conditions are necessary to maintain the integrity and properties of the fiberglass.

TECHNICAL PARAMETERS

| Linear Density (%) |

Moisture Content (%) |

Size Content (%) |

Stiffness (mm) |

| ISO 1889 |

ISO 3344 |

ISO 1887 |

ISO 3375 |

| ± 4 |

≤ 0.10 |

0.50 ± 0.15 |

110 ± 20 |

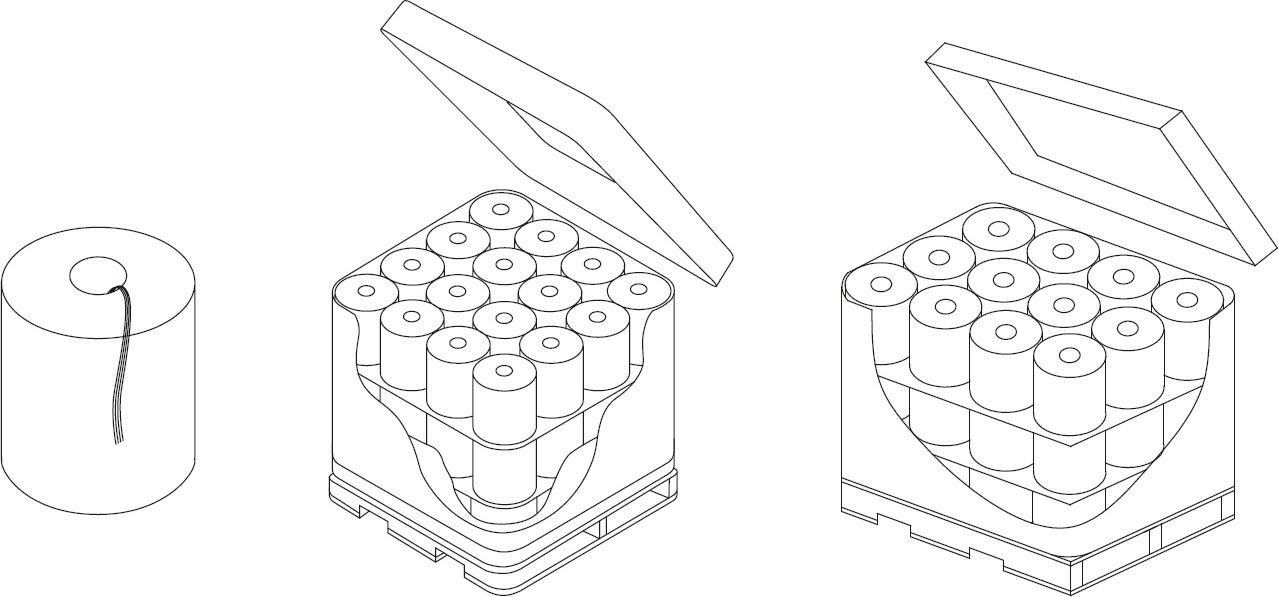

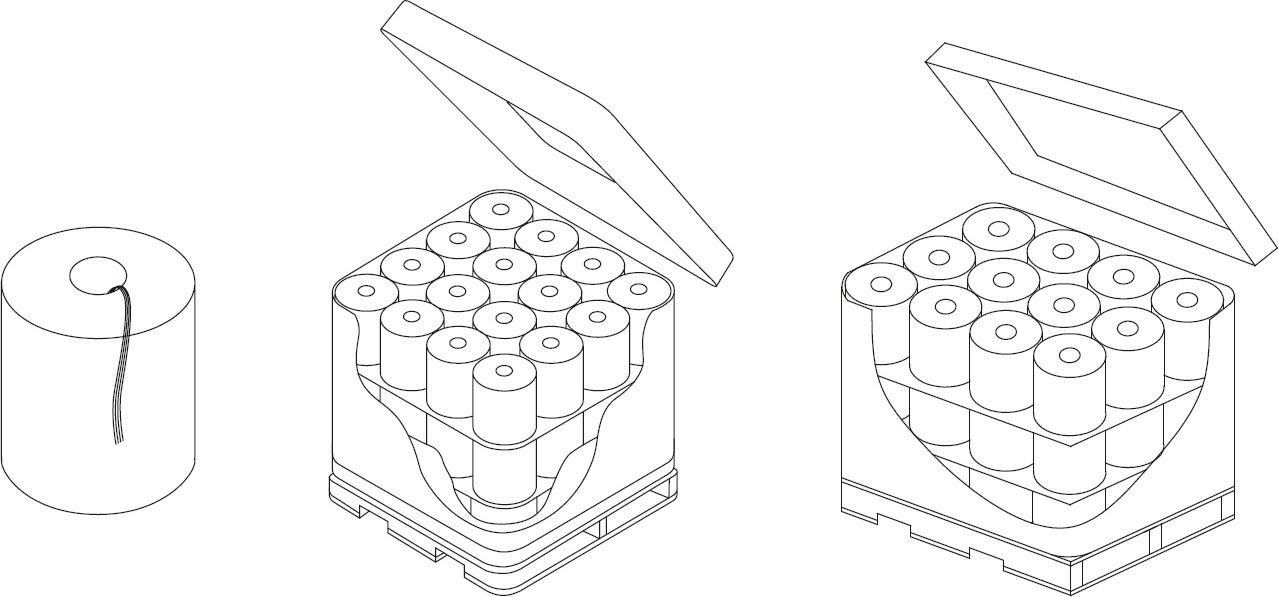

Packing

The product can be packed on pallets or in small cardboard boxes.

| Package height mm (in) |

260 (10.2)

|

260 (10.2)

|

| Package inside diameter mm (in) |

100 (3.9)

|

100 (3.9)

|

| Package outside diameter mm (in) |

270 (10.6)

|

310 (12.2)

|

| Package weight kg (lb) |

17 (37.5)

|

23 (50.7)

|

| Number of layers |

3

|

4

|

3

|

4

|

| Number of doffs per layer |

16

|

12

|

| Number of doffs per pallet |

48

|

64

|

36

|

48

|

| Net weight per pallet kg (lb) |

816 (1799)

|

1088 (2399)

|

828 (1826)

|

1104 (2434)

|

| Pallet length mm (in) |

1120 (44.1) |

1270 (50) |

| Pallet width mm (in) |

1120 (44.1) |

960 (37.8) |

| Pallet height mm (in) |

940 (37) |

1200 (47.2) |

940 (37) |

1200 (47.2) |