Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

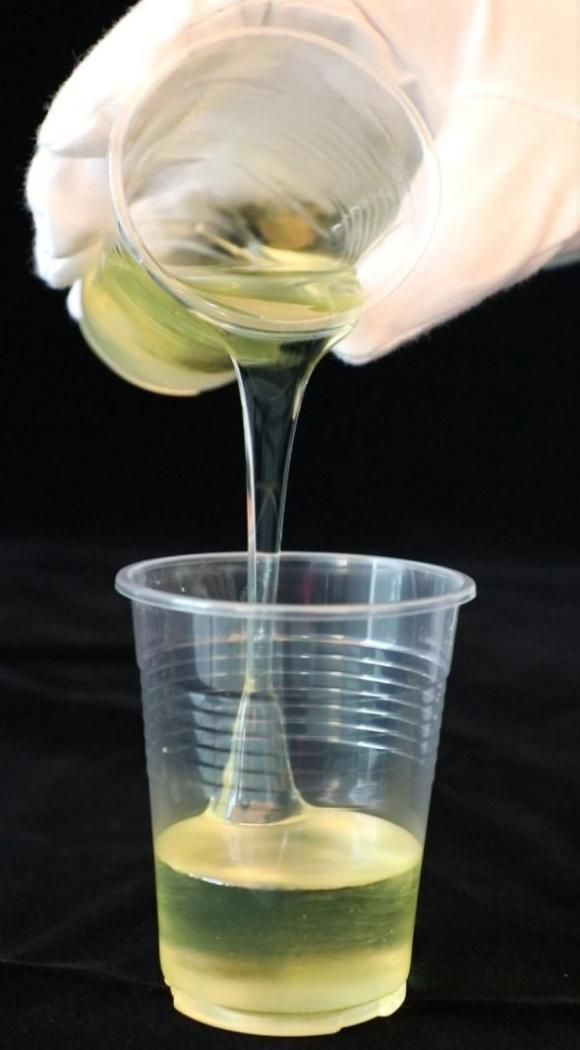

•MFE 770 vinyl ester resin is an epoxy novolac-based resin designed to provide exceptional thermal and chemical resistance properties at higher temperatures. It offers a high resistance to solvents and chemicals, good retention of strength and toughness at elevated temperatures, and excellent resistance to acidic oxidizing environments.

•FRP equipment produced using MFE 770 retains strength and toughness at elevated temperatures.

•MFE 770 is the second generation of MFE W1 (W2-1) which already successful used in heavy duty industrial applications over many years and provides an economical alternative to exotic alloys by allowing the use of lower cost FRP over traditional materials.

•Suitable for the applications such as FGD processes, industrial waste treatment facilities, metal pickling and solvent extraction processes used in mining.

•FRP fabrication process including contact moulding (hand lay-up), spray-up, pultrusion, infusion (RTM), etc.

•The formulation of heavy anti-corrosion coatings such as glass flake coatings.

•If you need higher temperature resistance, please consider MFE 780(casting HDT 160-166 °C),

MFE 780HT-300 (casting HDT 175 °C) or MFE 780HT-750 (casting HDT 200-210 °C).

Typical Liquid Resin Properties

|

Property (1) |

Value |

|

Viscosity, cps 25℃ |

230-370 |

|

Styrene Content |

34-40% |

|

Shelf Life (2) Dark, 25℃ |

6 months |

(1)Typical values, cannot be constructed as specifications

(2)Unopened drum with no additives, promoters, accelerators, etc. added. Shelf life specified from date of manufacture.

Typical Properties (1) Resin Clear Casting (3)

| Property | Value | Test Method |

| Tensile Strength/ MPa | 75-90 | |

| Tensile Modulus/ GPa | 3.4-3.8 | ASTM D-638 |

| Elongation at break / % | 3.0-4.0 | |

| Flexural Strength/ MPa | 130-145 | |

| ASTM D-790 | ||

| Flexural Modulus / GPa | 3.6-4.1 | |

| HDT (4) / °C | 145-150 | ASTM D-648 Method A |

| Barcol hardness | 40-46 | ASTM D2583 |

(3)Cure schedule: 24 hours at room temperature; 2 hours at 120C

(4)Maximum stress: 1.8 MPa

Safety and Handling Consideration

This resin contains ingredients which could be harmful if mishandled. Contact with skin and eyes should be avoided and necessary protective equipment and clothing should be worn. The specification is 2012 edition and may change with the technological improvement.

Sino Polymer Co., Ltd. maintains Material Safety Data Sheets on all of its products. Material Safety Data Sheets contain health and safety information for your development of appropriate product handling procedures to protect your employees and customers. Our Material Safety Data Sheets should be read and understood by all of your supervisory personnel and employees before using our products in your facilities.

Recommended Storage:

Drums – Store at temperatures below 25℃. Storage life decreases with increasing storage temperature. Avoid exposure to heat sources such as direct sunlight or steam pipes. To avoid contamination of product with water, do not store outdoors.

Keep sealed to prevent moisture pick-up and monomer loss. Rotate stock. For more information, please contact us at sale1@frp-cqdj.com

Package: 200kg per steel drum or 1000kg per IBC

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.