Introduction

Fiberglass roving is a crucial material in composite manufacturing, offering high strength, flexibility, and corrosion resistance. However, choosing between direct roving and assembled roving can significantly impact product performance, cost, and production efficiency.

This guide compares the two types, examining their manufacturing processes, mechanical properties, applications, and cost-effectiveness to help you make the best choice for your project.

What is Fiberglass Roving?

Fiberglass roving consists of continuous glass filaments bundled together for reinforcement in composites. It’s widely used in:

Pultrusion & filament winding

Sheet molding compound (SMC)

Boat hulls & automotive parts

Wind turbine blades

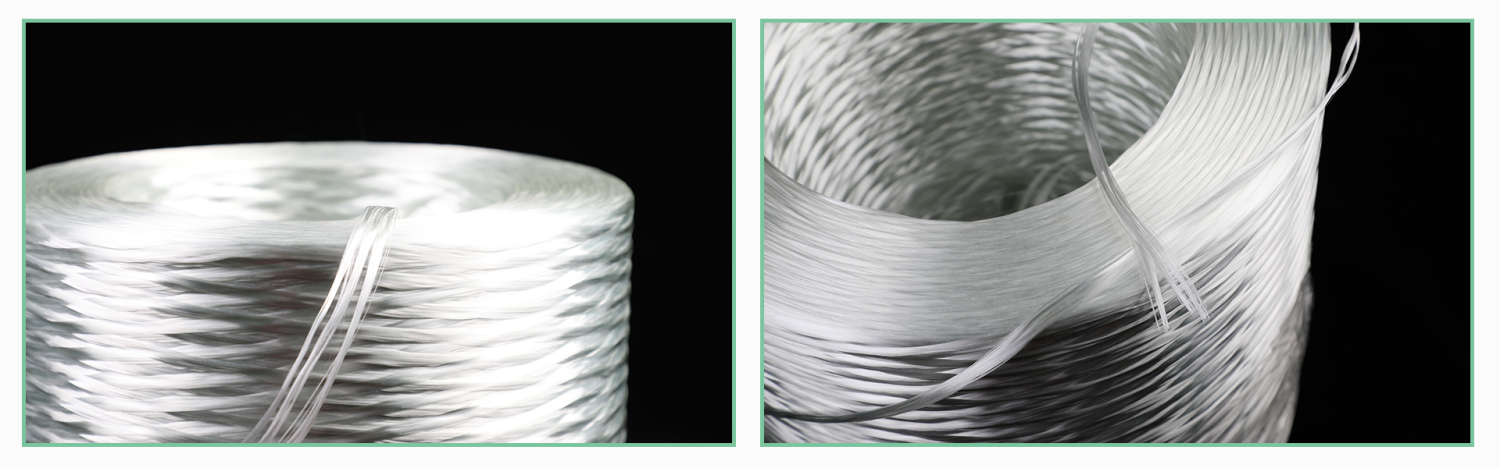

Fiberglass roving comes in two primary forms: direct roving and assembled roving, each with distinct advantages.

Direct Roving: Features and Benefits

Manufacturing Process

Fiberglass direct roving is produced by drawing molten glass directly into filaments, which are then wound into a package without twisting. This method ensures:

✔ Higher tensile strength (due to minimal filament damage)

✔ Better resin compatibility (uniform wet-out)

✔ Cost efficiency (fewer processing steps)

Key Advantages

Superior mechanical properties – Ideal for high-stress applications like aerospace and pressure vessels.

Faster production speeds – Preferred in automated processes like pultrusion.

Lower fuzz generation – Reduces equipment wear in molding.

Common Applications

Pultruded profiles (fiberglass beams, rods)

Filament-wound tanks & pipes

Automotive leaf springs

Assembled Roving: Features and Benefits

Manufacturing Process

Fiberglass assembled roving is made by gathering multiple smaller strands and bundling them together. This process allows:

✔ Better control over strand integrity

✔ Improved handling in manual processes

✔ More flexibility in weight distribution

Key Advantages

Easier to cut and handle – Preferred for hand lay-up and spray-up applications.

Better for complex shapes – Used in boat hulls and bathtub molding.

Lower cost for small-scale production – Suitable for workshops with limited automation.

Common Applications

Boat building & marine composites

Bathroom fixtures (tubs, showers)

Custom FRP parts

Direct vs. Assembled Roving: Key Differences

|

Factor |

Direct Roving |

Assembled Roving |

|

Strength |

Higher tensile strength |

Slightly lower due to bundling |

|

Resin Wet-Out |

Faster, more uniform |

May require more resin |

|

Production Speed |

Faster (automation-friendly) |

Slower (manual processes) |

|

Cost |

Lower (efficient production) |

Higher (additional processing) |

|

Best For |

Pultrusion, filament winding |

Hand lay-up, spray-up |

Which Should You Choose?

When to Use Direct Roving

✅ High-volume production (e.g., automotive parts)

✅ Applications needing maximum strength (e.g., wind turbine blades)

✅ Automated manufacturing processes

When to Use Assembled Roving

✅ Custom or small-batch production (e.g., boat repairs)

✅ Manual fabrication methods (e.g., artistic FRP sculptures)

✅ Projects requiring easy cutting & handling

Industry Trends & Future Outlook

The global fiberglass roving market is projected to grow at 5.8% CAGR (2024-2030) due to rising demand in wind energy, automotive lightweighting, and infrastructure. Innovations like eco-friendly roving (recycled glass) and smart rovings (embedded sensors) are emerging trends.

Conclusion

Choosing between direct and assembled roving depends on your production method, budget, and performance needs. Direct roving excels in high-speed, high-strength applications, while assembled roving is better for manual, custom fabrication.

Need expert advice? Consult a fiberglass supplier to match the right roving type to your project.

Post time: May-06-2025