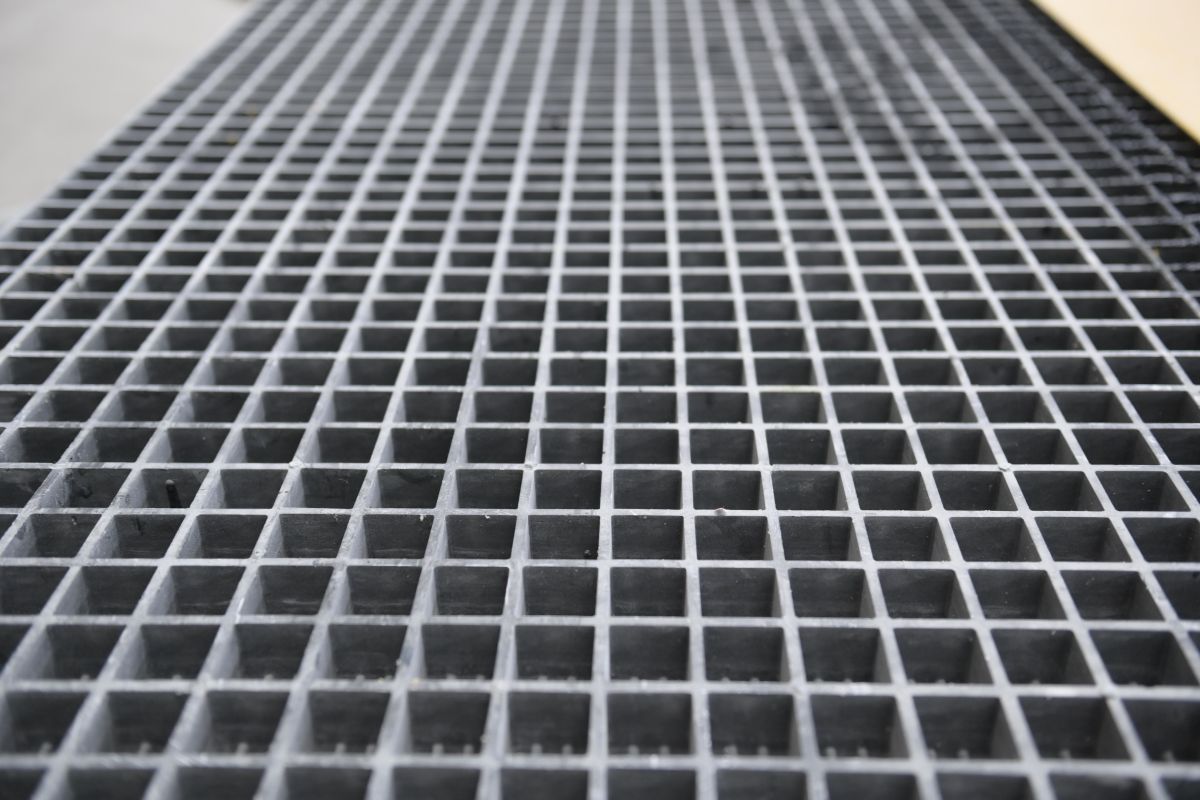

Fiberglass Molded Grating: A Versatile Solution for Diverse Applications

Fiberglass molded grating

Fiberglass molded grating has become a go-to choice for many different uses in industries, businesses, and building design due to its flexibility and dependability. Composed of reinforced fiberglass and resin, this type of grating offers a host of benefits, making it a preferred choice in various industries.

One of the most prominent advantages of fiberglass molded grating is its exceptional resistance to corrosion. Whether exposed to harsh chemicals, extreme moisture, or challenging environmental conditions, fiberglass grating maintains its structural integrity, making it an ideal option for marine, industrial, and chemical processing environments.

Beyond its corrosion resistance, fiberglass molded grating boasts an impressive strength-to-weight ratio, allowing it to support heavy loads while keeping the overall structure lightweight. This makes it an attractive option for applications where strength is essential, but minimizing structural weight is a priority.

The non-conductive nature of fiberglass grating also makes it a sought-after material in areas where electrical insulation and safety are crucial. You can rest easy knowing that this material doesn't conduct electricity.

Fiberglass molded grating is strong and can handle a lot of wear and tear. It's perfect for jobs that need a durable and tough material, plus it won't conduct electricity.

Furthermore, many fiberglass grating products are formulated to resist damage from ultraviolet (UV) radiation, ensuring long-term performance in outdoor and exposed environments. This UV resistance enhances the material's lifespan and reduces the need for frequent maintenance, resulting in cost savings over time.

Another vital feature of fiberglass molded grating is its fire resistance. With fire-retardant properties incorporated into its design, fiberglass grating provides increased safety in fire-prone areas, adding an extra layer of protection in critical applications.

The low-maintenance nature of fiberglass grating further enhances its appeal, as it reduces the need for regular upkeep, resulting in long-term cost efficiency for users across various industries.

Its versatility and durability position it as a leading material for demanding environments, offering long-term performance and cost-saving benefits for end-users.

As the demand for robust and reliable materials continues to grow across industries, fiberglass molded grating stands out as a leading solution, meeting the diverse needs of modern applications.

Some specific areas where fiberglass molded grating is commonly used include:

Industrial Facilities: Fiberglass grating is widely employed in industrial settings such as chemical plants, refineries, petrochemical facilities, and manufacturing plants due to its resistance to corrosion from chemicals and harsh environments. It is utilized for walkways, platforms, and flooring in areas that require a durable, non-conductive, and low-maintenance solution.

Marine and Offshore: In marine environments, including offshore oil platforms, docks, and shipyards, fiberglass grating is preferred for its resistance to corrosion from saltwater, durability in harsh weather conditions, and non-slip properties, making it ideal for use in walkways, decks, and flooring.

Water and Wastewater Treatment Plants: Fiberglass grating is commonly used in water and wastewater treatment facilities for walkways, platforms, and flooring due to its resistance to corrosion from water and chemicals, as well as its low maintenance requirements.

Power and Utilities: Fiberglass grating is employed in power plants, electrical substations, and utility facilities due to its non-conductive properties, which provide electrical insulation and safety benefits. It is used for flooring, walkways, and areas where electrical hazards are a concern.

Commercial and Architectural Buildings: In commercial and architectural settings, fiberglass grating is utilized for applications such as pedestrian bridges, outdoor walkways, pool decks, and access ramps due to its corrosion resistance, low-maintenance nature, and aesthetic appeal. Its UV resistance makes it suitable for outdoor use.

Transportation: Fiberglass grating is used in transportation infrastructure such as bridges, platforms, and airport walkways due to its strength, durability, and lightweight properties, which help reduce structural weight while maintaining load-bearing capacity.

These are just a few examples of the diverse applications of fiberglass molded grating, showcasing its value across a range of industries and settings where corrosion resistance, durability, non-conductivity, and low-maintenance requirements are vital considerations.

Types of fiberglass gratings

Certainly! Our company produces a range of high-quality fiberglass gratings to meet the diverse needs of our customers. Some of the types of fiberglass gratings we offer include:

Molded Fiberglass Grating: Our molded fiberglass grating is produced through a process where resin and continuous fiberglass strands are molded together under high pressure, resulting in a strong and durable grating with excellent corrosion resistance. This type of grating is well-suited for applications requiring high strength and impact resistance.

Pultruded Fiberglass Grating: Pultruded fiberglass grating is manufactured using a pultrusion process where continuous fiberglass rovings and fiberglass mats are pulled through a resin bath, then shaped and cured to form a strong, lightweight, and rigid grating. Pultruded gratings are known for their high strength-to-weight ratio and are ideal for applications requiring long spans and high load-bearing capacity.

Phenolic Grating: Our phenolic grating is made from a combination of synthetic resins, reinforced with continuous glass fibers and other additives. This type of grating offers excellent fire resistance, low smoke emission, and low toxicity, making it suitable for applications where fire safety is a priority, such as offshore and marine environments.

Mini-Mesh Grating: Mini-mesh fiberglass grating features a small aperture size, providing a solid surface while allowing for efficient drainage and reduced risk of small objects falling through. This type of grating is often used in industrial, commercial, and walkway applications where debris or small items must be contained, such as in food processing facilities and wastewater treatment plants.

Customer Inquiries

Our customers often inquire about the following aspects when considering our fiberglass gratings:

Corrosion Resistance: Customers are interested in the corrosion resistance properties of our fiberglass gratings, particularly in harsh or corrosive environments such as chemical plants, offshore platforms, and wastewater treatment facilities.

Load-Bearing Capacity: Many customers inquire about the load-bearing capacity of our fiberglass gratings, seeking solutions for heavy-duty industrial applications, bridges, walkways, and platforms.

Fire Resistance: For customers in industries such as oil and gas, offshore, and marine, fire resistance and compliance with safety standards are important considerations, leading to inquiries about our phenolic grating and other fire-rated options.

Customization: Customers often seek tailored solutions to meet specific project requirements, such as custom sizes, colors, and surface textures, and inquire about our ability to provide custom-made fiberglass gratings to suit their unique needs.

By addressing these aspects and understanding our customers' diverse requirements, we can provide them with the best-suited fiberglass grating solutions to meet their specific application needs.

Chongqing Dujiang Composites Co., Ltd.

Add:Northwest of Damotan, Tianma Village, Xiema Street, Beibei District, Chongqing, P.R.China

Web: www.frp-cqdj.com

Email: marketing@frp-cqdj.com

WhatsApp: +8615823184699

Post time: Feb-01-2024