Introduction

Fiberglass reinforcement materials are essential in composite manufacturing, construction, marine, and automotive industries. Two of the most commonly used products are fiberglass surface tissue and chopped strand mat (CSM). But which one is better for your specific needs?

This in-depth guide compares fiberglass surface tissue vs. chopped strand mat in terms of:

✔ Material composition

✔ Strength & durability

✔ Ease of application

✔ Cost-effectiveness

✔ Best use cases

By the end, you'll know exactly which material to choose for optimal performance.

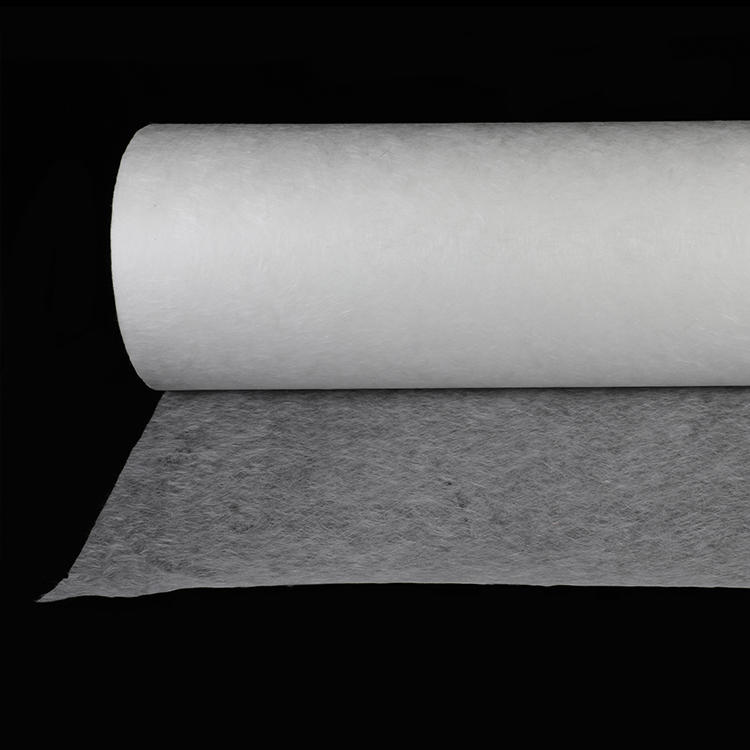

1. What is Fiberglass Surface Tissue?

Fiberglass surface tissue is a thin, non-woven veil made of fine glass fibers bonded with a resin-compatible binder. It is typically 10-50 gsm (grams per square meter) and used as a surface layer to improve finish quality.

Key Features:

✅ Ultra-thin & lightweight

✅ Smooth surface finish

✅ Resin-rich layer for corrosion resistance

✅ Reduces print-through in composites

Common Applications:

Automotive body panels

Boat hulls & marine laminates

Wind turbine blades

High-end composite molds

2. What is Chopped Strand Mat (CSM)?

Chopped strand mat consists of randomly oriented glass fibers (1.5-3 inches long) held together by a binder. It is heavier (300-600 gsm) and provides bulk reinforcement.

Key Features:

✅ High thickness & rigidity

✅ Excellent resin absorption

✅ Cost-effective for structural builds

✅ Easy to mold over complex shapes

Common Applications:

Fiberglass pools & tanks

DIY boat repairs

Roofing & industrial ducting

General-purpose laminates

3. Fiberglass Surface Tissue vs. Chopped Strand Mat: Key Differences

| Factor | Fiberglass Surface Tissue | Chopped Strand Mat (CSM) |

| Thickness | 10-50 gsm (thin) | 300-600 gsm (thick) |

| Strength | Surface smoothness | Structural reinforcement |

| Resin Usage | Low (resin-rich layer) | High (soaks up resin) |

| Cost | More expensive per m² | Cheaper per m² |

| Ease of Use | Requires skill for smooth finish | Easy to handle, good for beginners |

| Best For | Aesthetic finishes, corrosion resistance | Structural builds, repairs |

4. Which One Should You Choose?

✔ Choose Fiberglass Surface Tissue If…

You need a smooth, professional finish (e.g., car bodywork, yacht hulls).

You want to prevent print-through in gel-coated surfaces.

Your project requires chemical resistance (e.g., chemical tanks).

✔ Choose Chopped Strand Mat If…

You need thick, structural reinforcement (e.g., boat floors, storage tanks).

You're on a budget (CSM is cheaper per square meter).

You're a beginner (easier to handle than surface tissue).

5. Expert Tips for Using Both Materials

For Fiberglass Surface Tissue:

--- Use with epoxy or polyester resin for best adhesion.

--- Apply as the final layer for a smooth finish.

--- Roll out evenly to avoid wrinkles.

For Chopped Strand Mat:

--- Wet out thoroughly—CSM absorbs more resin.

--- Use multiple layers for added strength.

--- Ideal for hand lay-up and spray-up applications.

6. Industry Trends & Future Developments

Hybrid Solutions: Some manufacturers now combine surface tissue with CSM for balanced strength & finish.

Eco-Friendly Binders: New bio-based binders are making fiberglass materials more sustainable.

Automated Lay-Up: Robotics are improving precision in applying thin surface tissues.

Conclusion: Which is the Winner?

There’s no single "best" material—fiberglass surface tissue excels in finish quality, while chopped strand mat is better for structural builds.

For most projects:

Use CSM for bulk reinforcement (e.g., boat hulls, tanks).

Add surface tissue as a final layer for a smooth, professional look.

By understanding their differences, you can optimize costs, strengths, and aesthetics in your fiberglass projects.

Post time: Jun-27-2025