In the vast world of synthetic polymers, polyester stands as one of the most versatile and widely used families. However, a common point of confusion arises with the terms ”saturated” and ”unsaturated” polyester. While they share part of a name, their chemical structures, properties, and ultimate applications are worlds apart.

Understanding this distinction is not just academic—it’s crucial for engineers, product designers, manufacturers, and procurement specialists to select the right material for the job, ensuring performance, durability, and cost-effectiveness.

This definitive guide will demystify these two important polymer classes, providing you with the knowledge needed to make an informed decision for your next project.

The Core Difference: It’s All in the Chemical Bonds

The fundamental difference lies in their molecular backbone, specifically in the types of carbon-carbon bonds present.

● Unsaturated Polyester (UPR): This is the more common and widely recognized “polyester” in the composites industry. Its molecular chain contains reactive double bonds (C=C). These double bonds are the “unsaturation” points, and they act as potential cross-linking sites. UPRs are typically viscous, syrup-like resins that are liquid at room temperature.

● Saturated Polyester (SP): As the name implies, this polymer has a backbone consisting entirely of single bonds (C-C). There are no reactive double bonds available for cross-linking. Saturated polyesters are typically linear, high-molecular-weight thermoplastics that are solid at room temperature.

Think of it like this: Unsaturated Polyester is a set of Lego bricks with open connection points (the double bonds), ready to be locked together with other bricks (a cross-linking agent). Saturated Polyester is a set of bricks that have already been snapped together into a long, solid, and stable chain.

Deep Dive: Unsaturated Polyester (UPR)

Unsaturated Polyester Resins (UPRs) are thermosetting polymers. They require a chemical reaction to cure from a liquid into an infusible, rigid solid.

Chemistry and Curing Process:

UPR resins are created by reacting a diol (e.g., propylene glycol) with a combination of a saturated and an unsaturated dibasic acid (e.g., Phthalic Anhydride and Maleic Anhydride). The Maleic Anhydride provides the crucial double bonds.

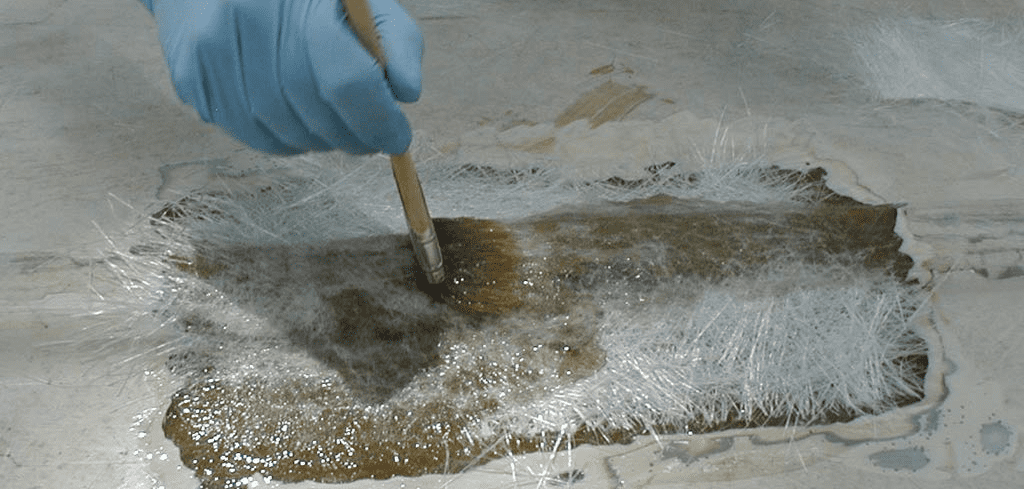

The magic happens during curing. The UPR resin is mixed with a reactive monomer, most commonly Styrene. When a catalyst (an organic peroxide like MEKP) is added, it initiates a free-radical polymerization reaction. The styrene molecules cross-link the adjacent UPR chains through their double bonds, creating a dense, three-dimensional network. This process is irreversible.

Key Properties:

Excellent Mechanical Strength: When cured, they are hard and rigid.

Superior Chemical and Heat Resistance: Highly resistant to water, acids, alkalis, and solvents.

Dimensional Stability: Low shrinkage during curing, especially when reinforced.

Ease of Processing: Can be used in a wide variety of techniques like hand lay-up, spray-up, resin transfer molding (RTM), and pultrusion.

Cost-Effective: Generally less expensive than epoxy resin and other high-performance resins.

Primary Applications:

UPRs are the workhorse of the fiberglass reinforced plastics (FRP) industry.

Marine: Boat hulls and decks.

Transportation: Car body panels, truck fairings.

Construction: Building panels, roofing sheets, sanitaryware (bathtubs, showers).

Pipes & Tanks: For chemical and water treatment plants.

Artificial Stone: Solid surfaces for countertops.

Deep Dive: Saturated Polyester (SP)

Saturated Polyesters are a family of thermoplastic polymers. They can be melted by heat, reshaped, and solidified upon cooling, a process that is reversible.

Chemistry and Structure:

The most common types of saturated polyesters are PET (Polyethylene Terephthalate) and PBT (Polybutylene Terephthalate). They are formed by the reaction of a diol with a saturated diacid (e.g., Terephthalic Acid or Dimethyl Terephthalate). The resulting chain has no sites for cross-linking, making it a linear, flexible polymer.

Key Properties:

High Toughness and Impact Resistance: Excellent durability and resistance to cracking.

Good Chemical Resistance: Resistant to a wide range of chemicals, though not as universal as UPRs.

Thermoplasticity: Can be injection molded, extruded, and thermoformed.

Excellent Barrier Properties: PET is renowned for its gas and moisture barrier qualities.

Good Wear and Abrasion Resistance: Makes it suitable for moving parts.

Primary Applications:

Saturated polyesters are ubiquitous in engineering plastics and packaging.

Packaging: PET is the primary material for plastic water and soda bottles, food containers, and blister packs.

Textiles: PET is the famous “polyester” used in clothing, carpets, and tire cord.

Engineering Plastics: PBT and PET are used for automotive parts (gears, sensors, connectors), electrical components (connectors, switches), and consumer appliances.

Head-to-Head Comparison Table

|

Feature |

Unsaturated Polyester (UPR) |

Saturated Polyester (SP – e.g., PET, PBT) |

|

Chemical Structure |

Reactive double bonds (C=C) in backbone |

No double bonds; all single bonds (C-C) |

|

Polymer Type |

Thermoset |

Thermoplastic |

|

Curing/Processing |

Irreversible chemical cure with styrene and catalyst |

Reversible melt-process (injection molding, extrusion) |

|

Typical Form |

Liquid resin |

Solid pellets or granules |

|

Key Strengths |

High rigidity, excellent chemical resistance, low cost |

High toughness, impact resistance, recyclability |

|

Key Weaknesses |

Brittle, styrene emission during curing, not recyclable |

Lower heat resistance than thermosets, susceptible to strong acids/bases |

|

Primary Applications |

Fiberglass boats, car parts, chemical tanks |

Drink bottles, textiles, engineering plastic parts |

How to Choose: Which One is Right for Your Project?

The choice between UPR and SP is rarely a dilemma once you define your requirements. Ask yourself these questions:

Choose Unsaturated Polyester (UPR) if:

You need a large, rigid, and strong part that will be produced at room temperature (like a boat hull).

Superior chemical resistance is a top priority (e.g., for chemical storage tanks).

You are using composite manufacturing techniques like hand lay-up or pultrusion.

Cost is a significant driving factor.

Choose Saturated Polyester (SP – PET, PBT) if:

You require a tough, impact-resistant component (like a gear or a protective housing).

You are using high-volume manufacturing like injection molding.

Recyclability or material re-use is important for your product or brand.

You need an excellent barrier material for packaging food and beverages.

Conclusion: Two Families, One Name

While “saturated” and “unsaturated” polyester sound similar, they represent two distinct branches of the polymer family tree with divergent paths. Unsaturated Polyester Resin is the thermosetting champion of high-strength, corrosion-resistant composites. Saturated Polyester is the thermoplastic workhorse behind the world’s most common plastics and textiles.

By understanding their core chemical differences, you can move beyond the confusion and leverage the unique advantages of each material. This knowledge empowers you to specify the right polymer, leading to better products, optimized processes, and ultimately, greater success in the marketplace.

Post time: Nov-22-2025