In the realm of composite materials, glass fiber stands out for its versatility, strength, and affordability, making it a cornerstone in the development of advanced composite mats. These materials, known for their exceptional mechanical and physical properties, have revolutionized various industries, from aerospace to automotive, and from construction to sports equipment.

Manufacturing Excellence and Material Properties

Glass fiber composite mats are engineered by embedding glass fibers within a polymer matrix, creating a material that combines the best attributes of both components. The glass fibers, drawn from molten silica mixtures, provide the composite with tensile strength and rigidity, while the polymer matrix encases the fibers, imparting resilience and shaping capabilities. This synergy results in a material that is not only strong and durable but also lightweight and resistant to many forms of environmental degradation.

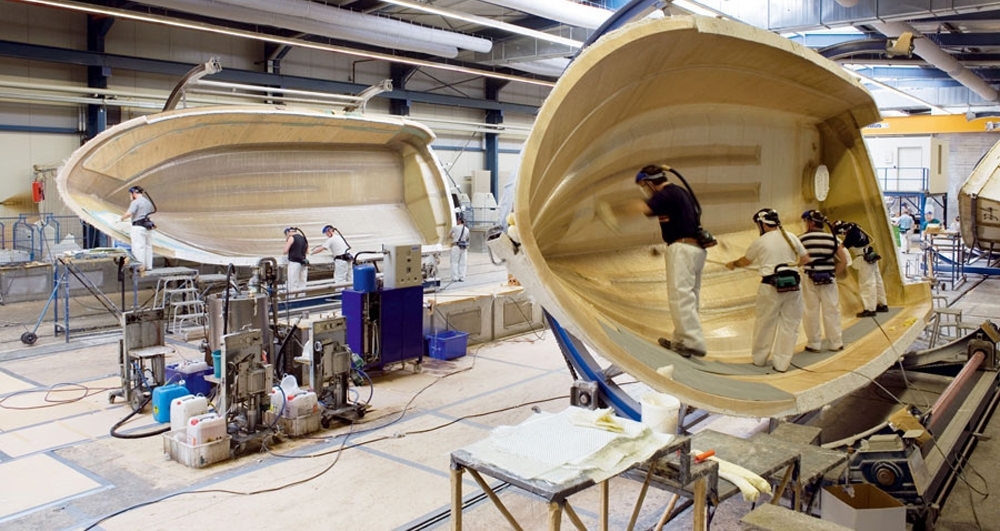

The production of glass fiber composite mat involves a series of steps that combine glass fibers with other materials to create a composite product with enhanced properties. The process is somewhat similar to the general manufacturing process of fiberglass, with additional steps for integrating the mat or nonwoven aspects.

Combining with Nonwoven Materials: To create glass fiber composite mat, the glass fibers are combined with nonwoven materials. This can be done through needling (mechanically intertwining the fibers), lamination (bonding layers together), or blending fibers before forming the nonwoven fabric.

Final Processing: The final composite mat product may undergo additional processes such as cutting to size, adding finishes for specific properties (e.g., water repellency, anti-static), and quality inspection before being packaged for shipment.

The production process of fiberglass composite mat itself is a marvel of modern manufacturing, involving the melting and extrusion of silica-based raw materials through fine bushings, producing filaments that are then gathered into strands, yarns, or rovings. These forms can be further processed or directly used in the creation of composite mats, depending on the application requirements.

Diverse Applications Across Industries

Fiberglass composite mat is a versatile material used in a wide range of applications due to its unique properties. Here are some common applications of fiberglass composite mats:

1. **Marine Industry**: Fiberglass composite mat is widely used in boat building and marine applications. It provides strength, durability, and resistance to corrosion, making it ideal for manufacturing boat hulls, decks, and other marine components.

2. **Construction**: In the construction industry, fiberglass composite mat is used for reinforcing concrete structures, providing additional strength and impact resistance. It is commonly employed in the production of fiberglass panels, roofing materials, and architectural elements.

3. **Automotive Sector**: Fiberglass composite mat finds applications in the automotive industry for manufacturing body panels, interior components, and structural reinforcements. Its lightweight nature and high strength make it a preferred material for enhancing vehicle performance.

4. **Industrial Equipment**: Fiberglass composite mat is utilized in the production of industrial equipment, such as storage tanks, pipes, and ducts. Its resistance to chemicals and environmental factors makes it suitable for various industrial applications.

5. **Recreational Products**: The material is used in the production of recreational vehicles, sports equipment, and leisure products. It provides a balance of strength and flexibility, making it suitable for applications such as RV components, surfboards, and kayaks.

6. **Infrastructure**: Fiberglass composite mat is employed in infrastructure projects for reinforcing bridges, walkways, and other structural elements. Its resistance to corrosion and high strength-to-weight ratio make it an attractive choice for infrastructure applications.

7. **Aerospace and Defense**: In the aerospace and defense sectors, fiberglass composite mat is used for manufacturing aircraft components, radomes, and military vehicles. Its lightweight properties contribute to fuel efficiency and performance.

8. **Renewable Energy**: Fiberglass composite mat is utilized in the production of components for renewable energy systems, such as wind turbine blades. Its durability and resistance to environmental factors make it suitable for these applications.

These applications highlight the versatility and widespread use of fiberglass composite mats across various industries, where its unique combination of properties makes it an essential material for numerous manufacturing processes.

Innovations and Sustainability

Recent advancements in glass fiber composite technology focus on enhancing performance while addressing environmental concerns. Recycling of glass fiber composites, once a significant challenge due to the difficulty of separating the composite components, has seen breakthroughs with new technologies enabling the recovery of fibers for reuse in high-value applications. Innovations in manufacturing processes and material formulations continue to push the boundaries of what glass fiber composites can achieve, including higher tensile strengths, improved environmental resistance, and greater compatibility with a range of polymer matrices.

Moreover, the industry is increasingly focusing on the sustainability of glass fiber composites. Efforts are being made to develop bio-based resins and to improve the energy efficiency of manufacturing processes, reducing the carbon footprint of these materials. The recycling and repurposing of glass fiber composites are also gaining traction, with research into new methods of reclaiming and reusing materials to minimize waste and environmental impact.

Conclusion

Glass fiber composite mats represent a critical development in material science, offering a combination of strength, durability, and versatility that is unmatched by traditional materials. As the industry continues to innovate, focusing on performance enhancement and sustainability, glass fiber composites are set to play an even more significant role in shaping the future of manufacturing, construction, and design. The ongoing research and development in this field promise not only to expand the applications of these materials but also to contribute to a more sustainable and efficient use of resources, marking a new era in the evolution of composite materials.

Contact Us

Phone number:+8615823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Mar-09-2024