Fiberglass surface mat could be a versatile material wide utilized in the development trade thanks to its sturdiness, light-weight nature, and resistance to corrosion. This non-woven material, made from randomly oriented glass fibers bonded with a resin-compatible binder, enhances structural integrity and surface smoothness in various applications.

In this article, we explore the top five applications of fiberglass surface mat in construction, highlighting its benefits and why it is a preferred choice for builders and engineers.

1. Waterproofing and Roofing Systems

Why Fiberglass Surface Mat is Ideal for Roofing

Fiberglass surface mat is extensively used in waterproofing membranes and roofing systems due to its excellent resistance to moisture, UV rays, and extreme weather conditions.

Enhanced Durability: The mat provides a strong, flexible base for asphalt and polymer-modified bitumen roofing systems, preventing cracks and leaks.

Seamless Protection: When used with liquid-applied coatings, it forms a continuous waterproof barrier, ideal for flat roofs and terraces.

Lightweight & Easy Installation: Unlike traditional materials, fiberglass mats reduce structural load while offering superior performance.

Common Uses:

Built-up roofing (BUR) systems

Single-ply membranes (TPO, PVC, EPDM)

Liquid waterproofing coatings

2. Reinforcing Concrete and Stucco Finishes

Preventing Cracks and Improving Strength

Fiberglass surface mat is embedded in thin-set concrete overlays, stucco, and exterior insulation finishing systems (EIFS) to prevent cracking and improve tensile strength.

Crack Resistance: The mat distributes stress evenly, reducing shrinkage cracks in plaster and stucco.

Impact Resistance: Reinforced surfaces withstand mechanical damage better than traditional finishes.

Smoother Finishes: It helps achieve a uniform surface texture in decorative concrete and architectural coatings.

Common Uses:

Exterior wall claddings

Decorative concrete overlays

Repairing damaged stucco surfaces

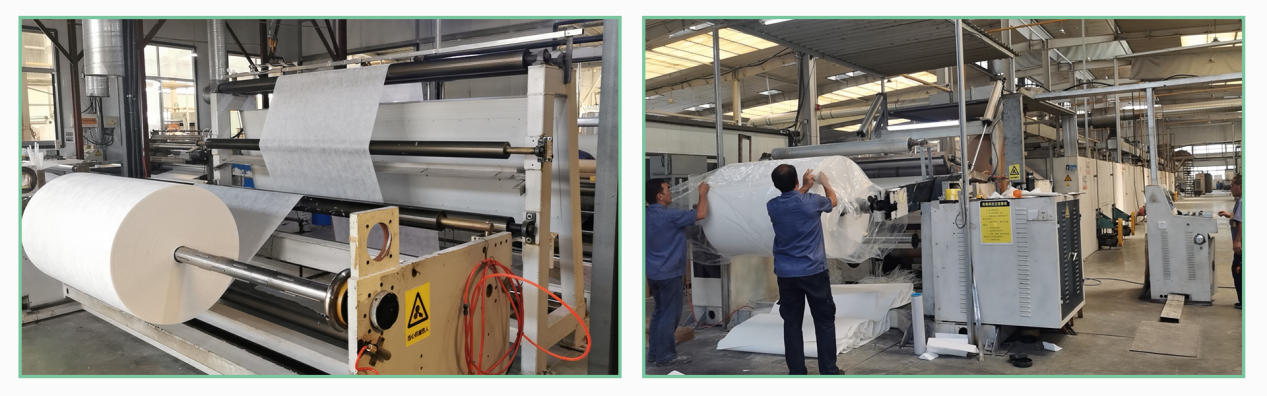

3. Composite Panel Manufacturing

Lightweight Yet Strong Construction Material

Fiberglass surface mat is a key component in composite panels used for wall partitions, ceilings, and modular construction.

High Strength-to-Weight Ratio: Ideal for prefabricated structures where weight reduction is crucial.

Fire Resistance: When combined with fire-retardant resins, it enhances safety in buildings.

Corrosion Resistance: Unlike metal panels, fiberglass-reinforced composites do not rust, making them perfect for humid environments.

Common Uses:

Sandwich panels for modular homes

False ceilings and decorative wall panels

Industrial partition walls

4. Flooring and Tile Backing

Improving Stability and Moisture Resistance

In flooring applications, fiberglass surface mat acts as a stabilizing layer beneath vinyl, laminate, and epoxy floors.

Prevents Warping: Adds dimensional stability to flooring systems.

Moisture Barrier: Reduces water absorption in tile backing boards.

Impact Absorption: Enhances durability in high-traffic areas.

Common Uses:

Vinyl composite tile (VCT) backing

Epoxy flooring reinforcement

Underlayment for wooden and laminate floors

5. Pipe and Tank Linings

Protecting Against Corrosion and Leaks

Fiberglass surface mat is widely used in lining pipes, tanks, and chemical storage vessels due to its resistance to corrosive substances.

Chemical Resistance: Withstands acids, alkalis, and solvents.

Longevity: Extends the lifespan of industrial piping systems.

Seamless Construction: Prevents leaks in wastewater and oil storage tanks.

Common Uses:

Sewage and water treatment pipes

Oil and gas storage tanks

Industrial chemical containment systems

Conclusion: Why Fiberglass Surface Mat is a Game-Changer in Construction

Fiberglass surface mat offers exceptional strength, durability, and versatility, making it indispensable in modern construction. From waterproofing roofs to reinforcing concrete and manufacturing composite panels, its applications are vast and growing.

Key Benefits Recap:

✔ Lightweight yet strong

✔ Resistant to water, chemicals, and UV rays

✔ Enhances crack resistance in coatings

✔ Improves the longevity of structural components

As construction trends shift towards lightweight, sustainable, and high-performance materials, fiberglass surface mat continues to play a pivotal role in innovative building solutions.

Post time: May-07-2025