Introduction

Fiberglass is a versatile material widely used in industries such as construction, automotive, marine, and aerospace due to its strength, durability, and lightweight properties. Two common forms of fiberglass reinforcement are chopped strand mat (CSM) and woven fiberglass fabric. While both serve as reinforcement in composite materials, they have distinct characteristics that make them suitable for different applications.

In this article, we will explore the key differences between chopped strand and woven fiberglass, including their manufacturing processes, mechanical properties, applications, and advantages.

1. Manufacturing Process

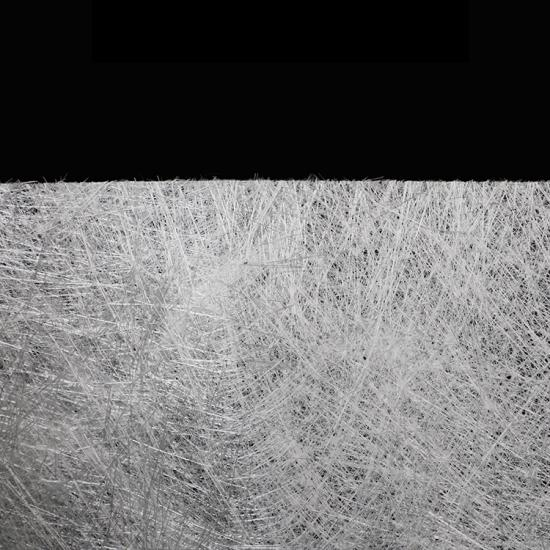

Chopped Strand Mat (CSM)

Made from randomly distributed short glass fibers (typically 1-2 inches long) bonded together with a resin-soluble binder.

Produced by chopping continuous glass strands and dispersing them onto a conveyor belt, where a binder is applied to hold them together.

Available in various weights (e.g., 1 oz/ft² to 3 oz/ft²) and thicknesses.

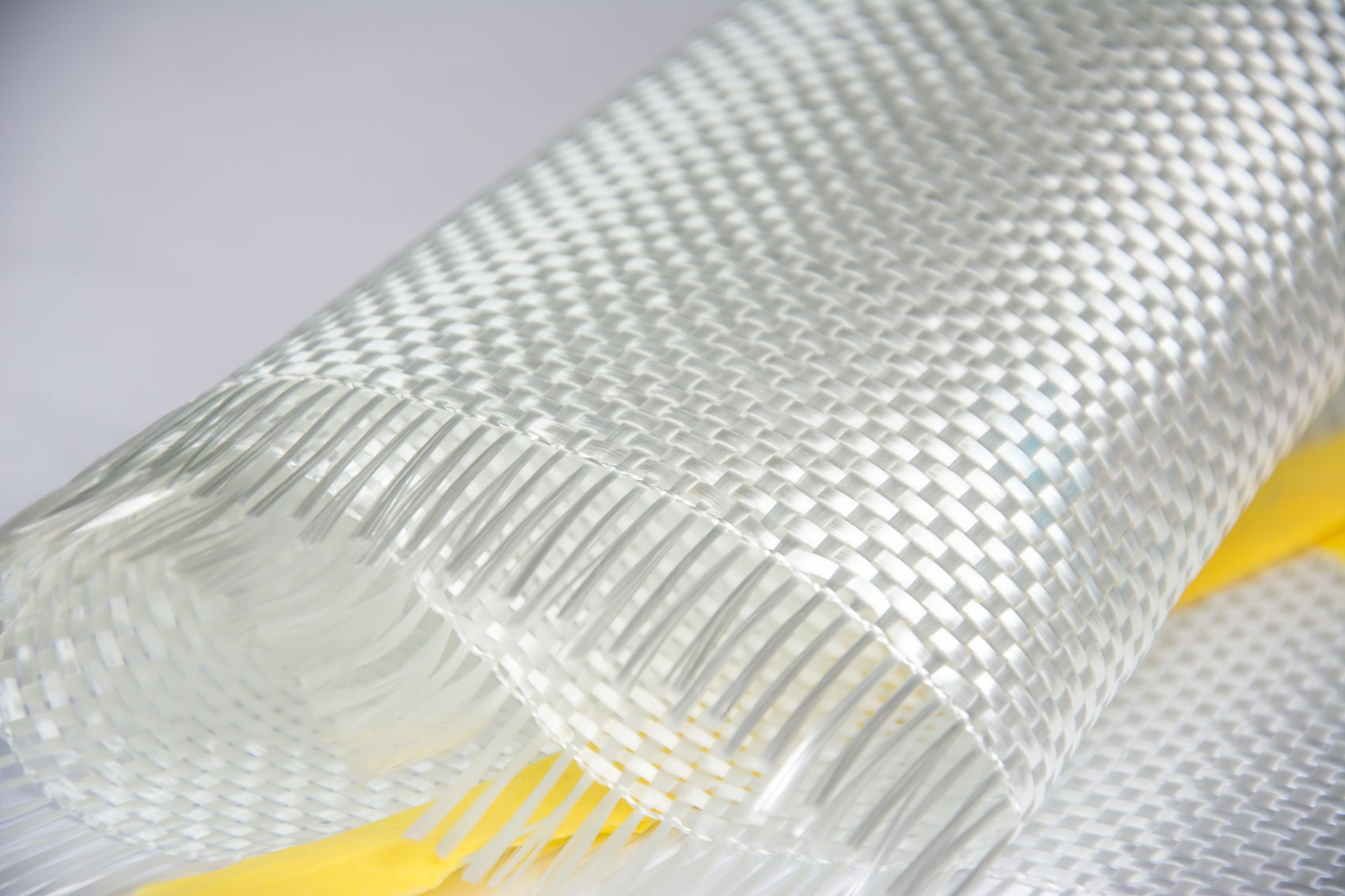

Woven Fiberglass Fabric

Made by weaving continuous glass fiber strands into a uniform pattern (e.g., plain weave, twill weave, or satin weave).

The weaving process creates a strong, grid-like structure with fibers running in 0° and 90° directions, providing directional strength.

Comes in different weights and weave styles, affecting flexibility and strength.

Key Difference:

CSM is non-directional (isotropic) due to random fiber orientation, while fiberglass woven roving is directional (anisotropic) due to its structured weave.

2. Mechanical Properties

| Property | Chopped Strand Mat (CSM) | Woven Fiberglass Fabric |

| Strength | Lower tensile strength due to random fibers | Higher tensile strength due to aligned fibers |

| Stiffness | Less stiff, more flexible | More rigid, maintains shape better |

| Impact Resistance | Good (fibers absorb energy randomly) | Excellent (fibers distribute load efficiently) |

| Conformability | Easier to mold into complex shapes | Less flexible, harder to drape over curves |

| Resin Absorption | Higher resin uptake (40-50%) | Lower resin uptake (30-40%) |

Why It Matters:

CSM is ideal for projects requiring easy shaping and uniform strength in all directions, such as boat hulls or shower enclosures.

Fiberglass woven roving is better for high-strength applications like automotive panels or structural components where directional reinforcement is needed.

3. Applications in Different Industries

Chopped Strand Mat (CSM) Uses:

✔ Marine Industry – Boat hulls, decks (good for waterproofing).

✔ Automotive – Non-structural parts like interior panels.

✔ Construction – Roofing, bathtubs, and shower stalls.

✔ Repair Work – Easy to layer for quick fixes.

Woven Fiberglass Fabric Uses:

✔ Aerospace – Lightweight, high-strength components.

✔ Automotive – Body panels, spoilers (needs high rigidity).

✔ Wind Energy – Turbine blades (requires directional strength).

✔ Sports Equipment – Bicycle frames, hockey sticks.

Key Takeaway:

CSM is best for low-cost, general-purpose reinforcement.

Woven fiberglass is preferred for high-performance, load-bearing applications.

4. Ease of Use & Handling

Chopped Strand Mat (CSM)

✅ Easier to cut and shape – Can be trimmed with scissors.

✅ Conforms well to curves – Ideal for complex molds.

✅ Requires more resin – Absorbs more liquid, increasing material costs.

Woven Fiberglass Fabric

✅ Stronger but less flexible – Needs precise cutting.

✅ Better for flat or slightly curved surfaces – Harder to drape over sharp bends.

✅ Less resin absorption – More cost-effective for large projects.

Pro Tip:

Beginners often prefer CSM because it’s forgiving and easy to work with.

Professionals choose fiberglass woven roving for precision and strength.

5. Cost Comparison

| Factor | Chopped Strand Mat (CSM) | Woven Fiberglass Fabric |

| Material Cost | Lower (simple manufacturing) | Higher (weaving adds cost) |

| Resin Usage | Higher (more resin needed) | Lower (less resin required) |

| Labor Cost | Faster to apply (easier handling) | More skill required (precise alignment) |

Which is More Economical?

CSM is cheaper upfront but may require more resin.

Fiberglass woven roving has a higher initial cost but offers better strength-to-weight ratio.

6. Which One Should You Choose?

When to Use Chopped Strand Mat (CSM):

Need quick, easy layup for complex shapes.

Working on non-structural, cosmetic, or repair projects.

Budget is a concern.

When to Use Woven Fiberglass Fabric:

Need high strength and rigidity.

Working on load-bearing structures (e.g., car parts, aircraft components).

Require better surface finish (woven fabric leaves a smoother finish).

Conclusion

Both chopped strand mat (CSM) and woven fiberglass fabric are essential reinforcement materials in composite manufacturing, but they serve different purposes.

CSM is affordable, easy to use, and great for general-purpose reinforcement.

Woven fiberglass is stronger, more durable, and ideal for high-performance applications.

Understanding their differences helps in selecting the right material for your project, ensuring optimal performance and cost-efficiency.

Post time: Jul-04-2025