When embarking on a fiberglass project, from boat building to custom automotive parts, one of the most fundamental questions arises: Which is stronger, fiberglass mat or cloth? The answer isn't a simple one, as "strong" can mean different things. The real key to success is understanding that fiberglass mat and cloth are designed for different purposes, and choosing the wrong one can lead to project failure.

This comprehensive guide will dissect the properties, strengths, and ideal applications of both fiberglass mat and cloth, empowering you to make the perfect choice for your specific needs.

The Quick Answer: It's About the Type of Strength

If you're looking for pure tensile strength—resistance to being pulled apart—fiberglass cloth is unequivocally stronger.

However, if you need stiffness, dimensional stability, and build-up thickness quickly, fiberglass mat has its own crucial advantages.

Think of it this way: Cloth is like the rebar in concrete, providing linear strength. Mat is like the aggregate, providing bulk and multi-directional stability. The best projects often use both strategically.

Deep Dive: Understanding Fiberglass Mat

Fiberglass mat, also known as "chopped strand mat" (CSM), is a non-woven material made from randomly oriented short glass fibers held together by a chemical binder.

Key Characteristics:

--Appearance: Opaque, white, and fluffy with a fuzzy texture.

--Structure: Random, interwoven fibers.

--Binder: Requires a styrene-based resin (like polyester or vinyl ester) to dissolve the binder and fully saturate the mat.

Strengths and Advantages:

Excellent Conformability: The random fibers allow the mat to easily stretch and conform to complex curves and compound shapes without wrinkling or bridging. This makes it ideal for molding intricate parts.

Rapid Thickness Buildup: Fiberglass Mat is very absorbent and can soak up a lot of resin, allowing you to build up laminate thickness quickly and cost-effectively.

Multi-Directional Strength: Because the fibers are randomly oriented, the strength is relatively equal in all directions across the plane of the fiberglass mat. It provides good isotropic properties.

High Stiffness: The resin-rich laminate created with mat results in a very rigid final product.

Cost-Effective: It is generally the least expensive type of fiberglass reinforcement.

Weaknesses:

Lower Tensile Strength: The short, random fibers and reliance on the resin matrix make it significantly weaker than woven fabrics under tension.

Heavier: The resin-to-glass ratio is high, resulting in a heavier laminate for a given thickness compared to cloth.

Messy to Work With: The loose fibers can shed and be irritating to the skin.

Limited Compatibility: The binder only dissolves in styrene, so it is not compatible with epoxy resin without special treatment, which is uncommon.

Ideal Uses for Fiberglass Mat:

Molding New Parts: Creating boat hulls, shower stalls, and custom body panels.

Backing Structures: Providing a stable backing layer on molds.

Repairs: Filling gaps and building up base layers in automotive body repair.

Laminating over Wood: Sealing and reinforcing wooden structures.

Deep Dive: Understanding Fiberglass Cloth

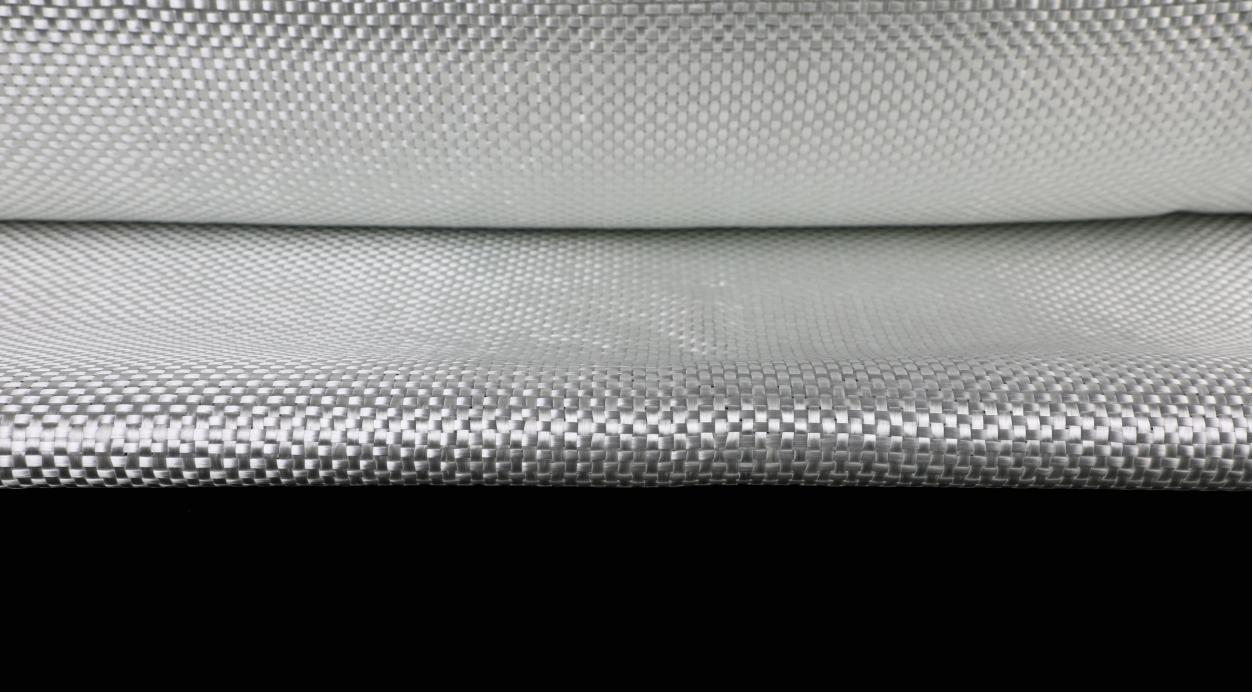

Fiberglass cloth is a woven fabric, similar in appearance to regular cloth, but made from continuous glass filaments. It is available in different weave patterns (like plain, twill, or satin) and weights.

Key Characteristics:

Appearance: Smooth, with a visible grid-like pattern. It is often more translucent than mat.

Structure: Woven, continuous fibers.

Resin Compatibility: Works excellently with both polyester and epoxy resins.

Strengths and Advantages:

Superior Tensile Strength: The continuous, woven filaments create an incredibly strong network that is highly resistant to pulling and stretching forces. This is its defining advantage.

Smooth, Finish-Quality Surface: When properly saturated, cloth creates a much smoother surface with less print-through, making it ideal for the final layer of a laminate that will be visible or painted.

Higher Strength-to-Weight Ratio: Fiberglass woven roving laminates are stronger and lighter than mat laminates of the same thickness because they have a higher glass-to-resin ratio.

Excellent Compatibility: It is the reinforcement of choice for high-performance projects using epoxy resin.

Durability and Impact Resistance: The continuous fibers are better at distributing impact loads, making the laminate tougher.

Weaknesses:

Poor Conformability: It does not easily drape over complex curves. The weave can bridge gaps or wrinkle, requiring strategic cutting and darts.

Slower Thickness Buildup: It is less absorbent than mat, so building thick laminates requires more layers, which is more expensive.

Higher Cost: Fiberglass cloth is more expensive than mat per square foot.

Ideal Uses for Fiberglass Cloth:

Structural Skins: Aircraft components, high-performance kayaks, and carbon-fiber-alternative parts.

Waterproofing: Sealing and strengthening wooden boats (e.g., the "epoxy & glass" method).

Final Cosmetic Layers: The outer layer on custom car parts, surfboards, and furniture for a smooth finish.

Reinforcing High-Stress Areas: Joints, corners, and mounting points that undergo significant load.

Head-to-Head Comparison Table

|

Property |

Fiberglass Mat (CSM) |

Fiberglass Cloth |

|

Tensile Strength |

Low |

Very High |

|

Stiffness |

High |

Moderate to High |

|

Conformability |

Excellent |

Fair to Poor |

|

Thickness Buildup |

Fast & Cheap |

Slow & Expensive |

|

Finish Quality |

Rough, Fuzzy |

Smooth |

|

Weight |

Heavier (resin-rich) |

Lighter |

|

Primary Resin |

Polyester/Vinyl Ester |

Epoxy, Polyester |

|

Cost |

Low |

High |

|

Best For |

Complex molds, bulk, cost |

Structural strength, finish, light weight |

The Pro's Secret: Hybrid Laminates

For many professional-grade applications, the strongest solution isn't one or the other—it's both. A hybrid laminate leverages the unique benefits of each material.

A Typical Laminate Schedule Might Look Like This:

1.Gel Coat: The cosmetic outer surface.

2.Surface Veil: (Optional) For an ultra-smooth finish beneath the gel coat.

3.Fiberglass Cloth: Provides the primary structural strength and a smooth base.

4.Fiberglass Mat: Acts as a core, adding thickness, stiffness, and creating a excellent bonding surface for the next layer.

5.Fiberglass Cloth: Another layer for added strength.

6.Core Material (e.g., wood, foam): Sandwiched for ultimate stiffness.

7.Repeat on the inside.

This combination creates a composite structure that is incredibly strong, rigid, and durable, resisting both tensile forces and impact.

Conclusion: Making the Right Choice for You

So, which is stronger, fiberglass mat or cloth? You now know it's the wrong question. The right question is: "What do I need my project to do?"

Choose Fiberglass Mat if: You are making a mold, need to build thickness fast, are working on a tight budget, or have complex, curved surfaces. It's the workhorse for general fabrication and repair.

Choose Fiberglass Cloth if: Your project demands maximum strength and light weight, you need a smooth final finish, or you are using epoxy resin. It's the choice for high-performance and structural applications.

By understanding the distinct roles of fiberglass mat and cloth, you are no longer just guessing. You are engineering your project for success, ensuring it is not only strong but also durable, fit-for-purpose, and professionally finished. Invest in the right materials, and your project will reward you for years to come.

Post time: Nov-17-2025