Product Detail

Product Tags

Related Video

Feedback (2)

Our aim would be to fulfill our shoppers by offering golden company, very good value and good quality for Silica Glass Fabric, E-Glass Woven Roving Combo Mat, Alkali-Resistant Fibreglass Spray Up Roving, Because we stay in this line about 10 years. We got best suppliers support on quality and price. And we had weed out suppliers with poor quality. Now many OEM factories cooperated with us too.

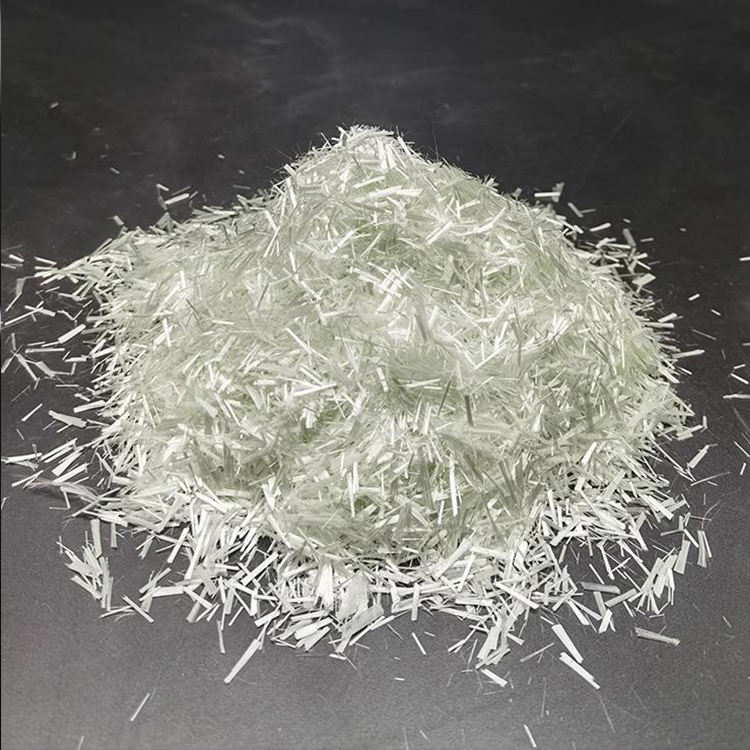

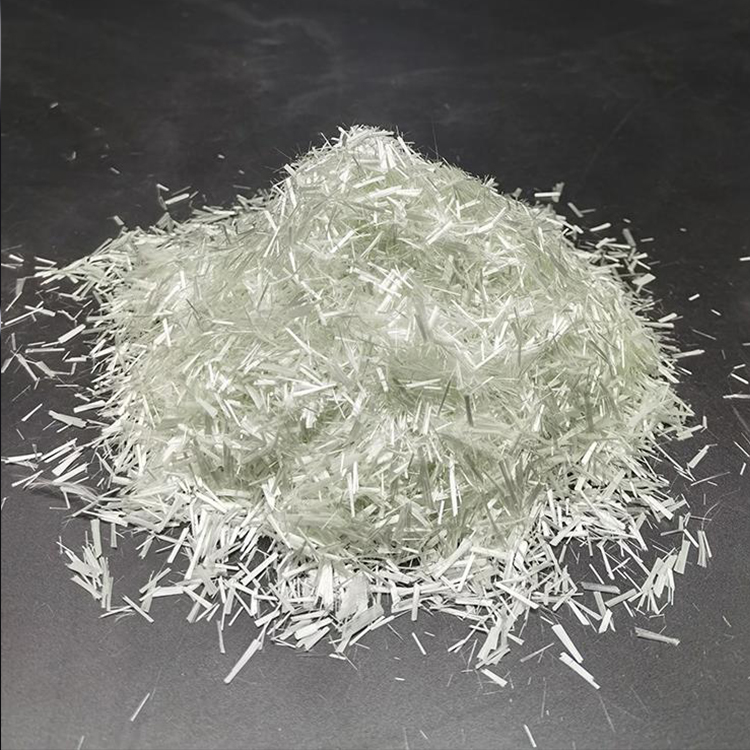

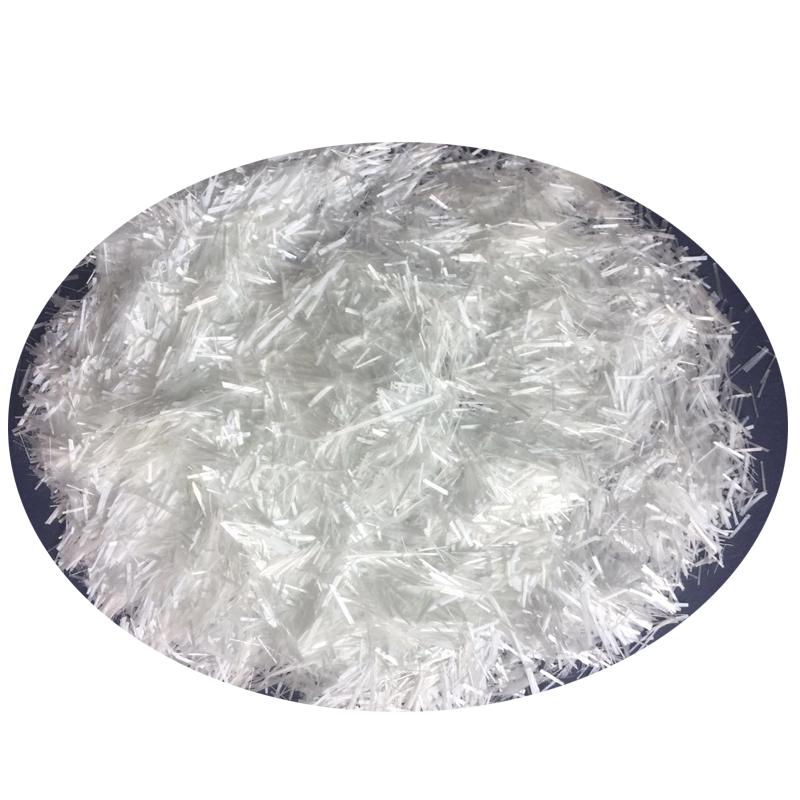

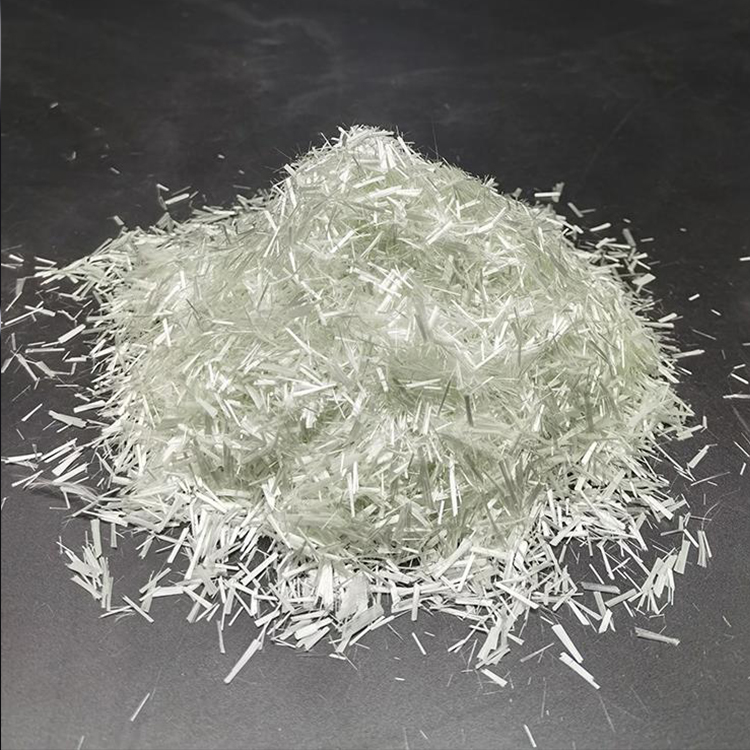

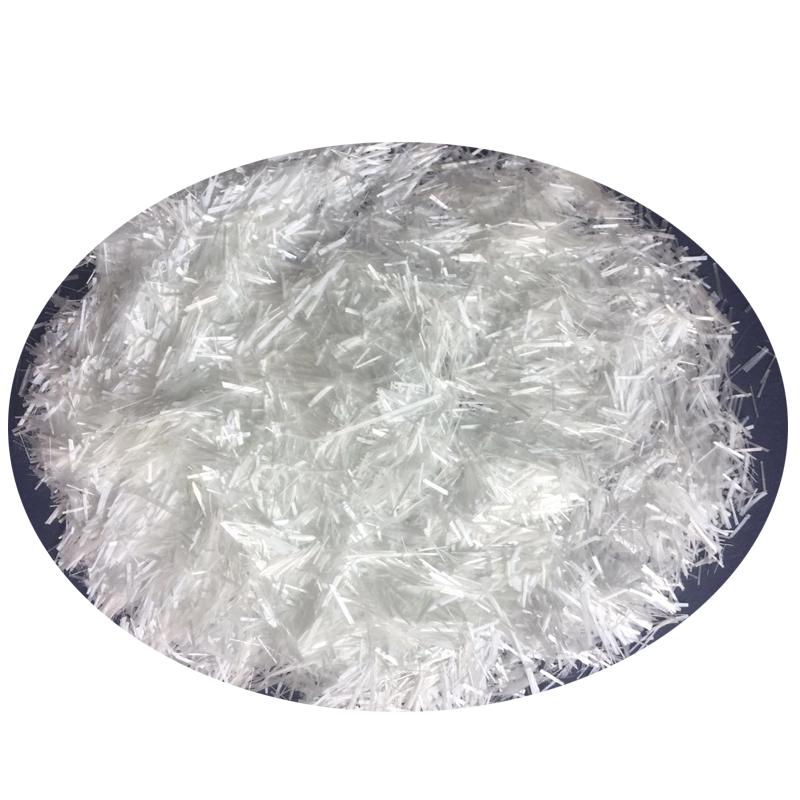

Fiberglass Chopped Strands Fiberglass E-Glass Chopped Fiberglass Strands For Concrete Detail:

PROPERTY

Application

- Composite Manufacturing: Fiberglass chopped strands are extensively used as reinforcement in composite materials such as fiberglass-reinforced plastics (FRP), also known as fiberglass composites. These composites are widely used in automotive parts, boat hulls, aerospace components, sporting goods, and construction materials.

- Automotive Industry: Fiberglass chopped strands are used in automotive applications for manufacturing lightweight and durable components such as body panels, bumpers, interior trim, and structural reinforcements. These components benefit from the high strength-to-weight ratio of fiberglass composites.

- Marine Industry: Fiberglass chopped strands are utilized in the marine industry for manufacturing boat hulls, decks, bulkheads, and other structural components. Fiberglass composites offer excellent resistance to corrosion, moisture, and harsh marine environments, making them ideal for marine applications.

- Construction Materials: Fiberglass chopped strands are incorporated into construction materials such as fiberglass-reinforced concrete (GFRC), fiberglass-reinforced polymer (FRP) bars, and panels. These materials provide enhanced strength, durability, and corrosion resistance, making them suitable for various construction applications, including bridges, buildings, and infrastructure.

- Wind Energy: Fiberglass chopped strands are used in the manufacturing of wind turbine blades, rotor hubs, and nacelles. Fiberglass composites offer the necessary strength, stiffness, and fatigue resistance required for wind energy applications, contributing to the efficient generation of renewable energy.

- Electrical and Electronics: Fiberglass chopped strands are employed in electrical and electronic applications for manufacturing insulating materials, circuit boards, and electrical enclosures. Fiberglass composites provide excellent electrical insulation properties and can withstand high temperatures, making them suitable for use in electrical devices and equipment.

- Recreational Products: Fiberglass chopped strands are used in the production of recreational products such as surfboards, snowboards, kayaks, and recreational vehicles (RVs). Fiberglass composites offer lightweight, durable, and high-performance materials for various outdoor and recreational activities.

- Industrial Applications: Fiberglass chopped strands find applications in various industrial sectors, including chemical processing, oil and gas, mining, and wastewater treatment. Fiberglass composites are used for manufacturing corrosion-resistant tanks, pipes, ducts, and equipment that withstand harsh chemical environments.

Feature:

- Length Variation: Chopped fiberglass strands come in various lengths, typically ranging from a few millimeters to several centimeters. The choice of strand length depends on the specific application requirements, with shorter strands providing better dispersion and longer strands offering increased reinforcement.

- High Strength-to-Weight Ratio: Fiberglass is known for its high strength-to-weight ratio, making chopped fiberglass strands an excellent choice for lightweight yet strong composite materials. This property allows for the production of durable and structurally sound components without adding significant weight.

- Uniform Distribution: Chopped fiberglass strands facilitate the uniform distribution of reinforcement within composite materials. Proper dispersion of the strands ensures consistent mechanical properties throughout the finished product, reducing the risk of weak spots or uneven performance.

- Compatibility with Resins: Chopped fiberglass strands are compatible with a wide range of resin systems, including polyester, epoxy, vinyl ester, and phenolic resins. This compatibility allows manufacturers to tailor composite formulations to meet specific performance requirements for various applications.

- Adhesion Enhancement: Chopped fiberglass strands are typically coated with sizing agents to improve adhesion to resin matrices during composite processing. This coating promotes strong bonding between the strands and the resin, enhancing the overall strength and durability of the composite material.

- Flexibility and Conformability: Chopped fiberglass strands offer flexibility and conformability, allowing them to be easily molded into complex shapes and contours. This feature makes them suitable for a wide range of manufacturing processes, including compression molding, injection molding, filament winding, and hand lay-up.

- Chemical Resistance: Fiberglass chopped strands exhibit excellent resistance to a wide range of chemicals, including acids, alkalis, solvents, and corrosive substances. This property makes fiberglass-reinforced composites suitable for use in environments where exposure to harsh chemicals is a concern.

- Thermal Stability: Chopped fiberglass strands maintain their structural integrity and mechanical properties over a wide temperature range. This thermal stability allows composite materials reinforced with fiberglass strands to withstand high temperatures without compromising performance.

- Corrosion Resistance: Fiberglass chopped strands offer exceptional resistance to corrosion, rust, and degradation caused by exposure to moisture, humidity, and environmental elements. This corrosion resistance extends the lifespan of composite materials used in outdoor and marine applications.

- Electrical Insulation: Fiberglass is an excellent electrical insulator, making chopped fiberglass strands suitable for use in electrical and electronic applications. Composite materials reinforced with fiberglass provide insulation against electrical currents, preventing electrical conductivity and ensuring safety.

Key Technical Data:

| CS |

Glass Type |

Chopped Length(mm) |

Diameter(um) |

MOL(%) |

| CS3 |

E-glass |

3 |

7-13 |

10-20±0.2 |

| CS4.5 |

E-glass |

4.5 |

7-13 |

10-20±0.2 |

| CS6 |

E-glass |

6 |

7-13 |

10-20±0.2 |

| CS9 |

E-glass |

9 |

7-13 |

10-20±0.2 |

| CS12 |

E-glass |

12 |

7-13 |

10-20±0.2 |

| CS25 |

E-glass |

25 |

7-13 |

10-20±0.2 |

Product detail pictures:

Related Product Guide:

Bear "Customer 1st, Good quality first" in mind, we work closely with our prospects and supply them with efficient and professional services for Fiberglass Chopped Strands Fiberglass E-Glass Chopped Fiberglass Strands For Concrete , The product will supply to all over the world, such as: Saudi Arabia, Paris, Cannes, We put the product quality and customer's benefits to the first place. Our experienced salesmen supply prompt and efficient service. Quality control group make sure the best quality. We believe quality comes from detail. If you have demand, allow us to work together to get success.

We are really happy to find such a manufacturer that ensuring product quality at the same time the price is very cheap.

By Eric from Swedish - 2017.11.12 12:31

By Eric from Swedish - 2017.11.12 12:31

Although we are a small company, we are also respected. Reliable quality, sincere service and good credit, we are honored to be able to work with you!

By Anna from Malta - 2018.10.01 14:14

By Anna from Malta - 2018.10.01 14:14