Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

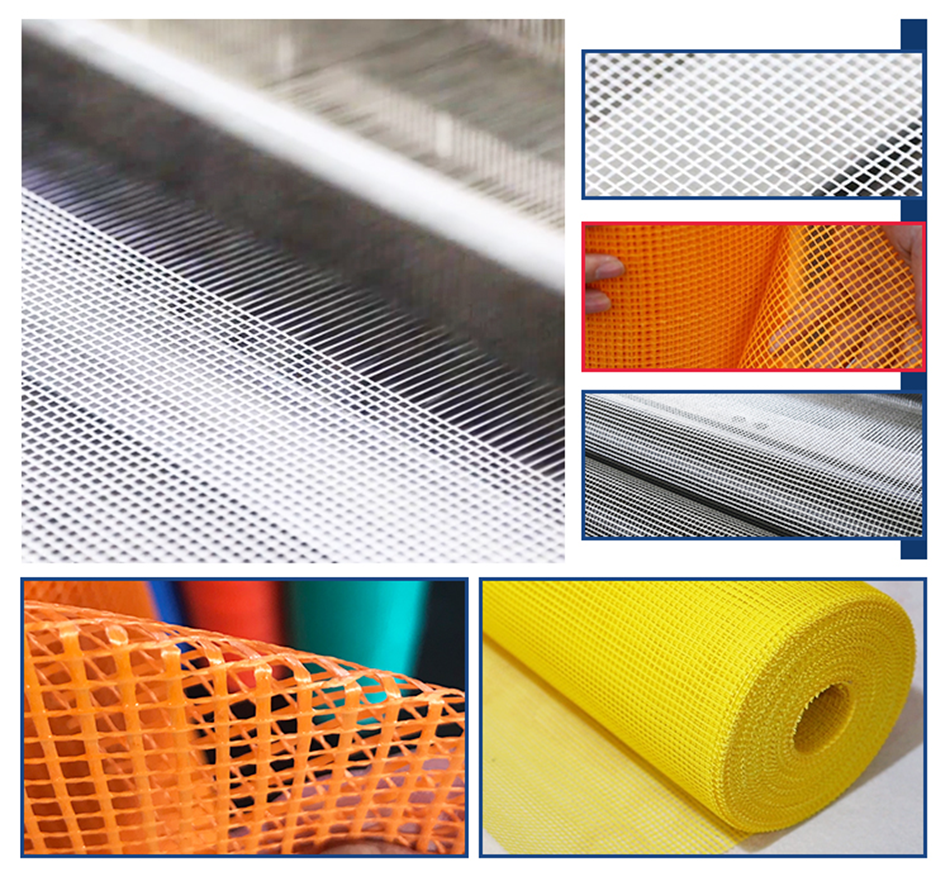

We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for High Quality China Fiberglass Mesh India/Fiberglass Woven Fabric/ Glass Fiber Reinforced Concrete, Welcome your visiting and any your inquires,sincerely hope we can have chance to cooperate with you and we can build-up prolonged perfectly organization connection along with you.

We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for China Glass Fiber Mesh, Fiber Glass, Our product quality is one of the major concerns and has been produced to meet the customer’s standards. “Customer services and relationship” is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

• Good chemical stability:Alkali-resistant, acid-resistant, waterproof, cement erosion-resistant, and other chemical corrosion resistant, and strong resin bonding, soluble in styrene.

• Outstanding process:Include coating enough alkali-resist glue, our coating glue is produced by Germany BASF which can keep 60-80% strength after 28-day immersion of 5% Na(OH) solution, so that guarantee high strength, high tensility, light weight.

• Fiberglass yarn is supplied by Jushi Group:which is the largest producer of fiberglass yarn in the world like Saint Gobain, it own 20% extra strength and beauty surface than normal fiberglass yarn.

• Strength retention rate > 90%, elongation <1%,the durability of more than 50 years.

• Good dimensional stability, stiffness, smoothness an difficult to shrink and deformation, good positioning property..

• Good impact resistance and not easy to be teared.

• Fire resistant, thermal insulation, sound insulation, insulations etc.

• Wall reinforced material (such as fiberglass wall mesh, GRC wall panels etc).

• Reinforced cement products.

• Used for Granite, mosaic, marble back mesh etc.

• Waterproof membrane fabric, asphalt roofing.

• Framework material for reinforced plastics, rubber products,.

• Fire board.

• Grinding wheel base fabric.

• Road surface with geogrid.

• Construction caulking tape etc.

• 16×16 mesh, 12×12 mesh, 9×9 mesh, 6×6 mesh, 4×4 mesh, 2.5×2.5 mesh

15×14 mesh, 10×10 mesh, 8×8 mesh, 5×4 mesh, 3×3 mesh, 1×1 mesh and so on.

• Weight/sq.meter: 40g—800g

• Each roll length: 10m, 20m, 30m, 50m—300m

• Width: 1m—2.2m

• Color: White (standard) blue, green, orange, yellow and others.

• We can produce many specifications and use different packaging according to customers’requests.

• 75g / m2 or less: Used in the reinforcement of thin slurry .

• 110g / m2 or about: Widely used in indoor and outdoor walls .

• 145g/m2 or about: Used in the wall and be mixed in various materials.

• 160g / m2 or about: Used in insulator layer of reinforcement in the mortar.

|

Item Number |

Yarn(Tex) |

Mesh(mm) |

Density Count/25mm |

Tensile Strength × 20cm |

Woven Structure

|

Content of resin%

|

||||

| Warp |

Weft |

Warp |

Weft |

Warp |

Weft |

Warp |

Weft |

|||

|

45g2.5×2.5 |

33×2 |

33 |

2.5 |

2.5 |

10 |

10 |

550 |

300 |

Leno |

18 |

|

60g2.5×2.5 |

40×2 |

40 |

2.5 |

2.5 |

10 |

10 |

550 |

650 |

Leno |

18 |

|

70g 5×5 |

45×2 |

200 |

5 |

5 |

5 |

5 |

550 |

850 |

Leno |

18 |

|

80g 5×5 |

67×2 |

200 |

5 |

5 |

5 |

5 |

700 |

850 |

Leno |

18 |

|

90g 5×5 |

67×2 |

250 |

5 |

5 |

5 |

5 |

700 |

1050 |

Leno |

18 |

|

110g 5×5 |

100×2 |

250 |

5 |

5 |

5 |

5 |

800 |

1050 |

Leno |

18 |

|

125g 5×5 |

134×2 |

250 |

5 |

5 |

5 |

5 |

1200 |

1300 |

Leno |

18 |

|

135g 5×5 |

134×2 |

300 |

5 |

5 |

5 |

5 |

1300 |

1400 |

Leno |

18 |

|

145g 5×5 |

134×2 |

360 |

5 |

5 |

5 |

5 |

1200 |

1300 |

Leno |

18 |

|

150g 4×5 |

134×2 |

300 |

4 |

5 |

6 |

5 |

1300 |

1300 |

Leno |

18 |

|

160g 5×5 |

134×2 |

400 |

5 |

5 |

5 |

5 |

1450 |

1600 |

Leno |

18 |

|

160g 4×4 |

134×2 |

300 |

4 |

4 |

6 |

6 |

1550 |

1650 |

Leno |

18 |

|

165g 4×5 |

134×2 |

350 |

4 |

5 |

6 |

5 |

1300 |

1300 |

Leno |

18 |

·Fiber glass mesh is usually wrapped by polyethylene bag,then 4rolls are put into a suitable corrugated carton.

·A 20 feet standard container can fill about 70000m2 fiberglass mesh,a 40 feet container can fill about 15000

m2 of fiberglass net cloth.

·Fiberglass mesh should be stored in a cool, dry, water-proof area. It is recommended that the room

temperature and humidity be always maintained at 10℃ to 30℃ and 50% to 75% respectively.

·Please keep the product in its original packaging before being used for no more than 12 months, avoiding

moisture absorption.

·Delivery Detail:15-20 days after receive the advance payment.

We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for High Quality China Fiberglass Mesh India/Fiberglass Woven Fabric/ Glass Fiber Reinforced Concrete, Welcome your visiting and any your inquires,sincerely hope we can have chance to cooperate with you and we can build-up prolonged perfectly organization connection along with you.

We’ll make each individual effort to become exceptional and ideal, and speed up our steps for standing inside the rank of worldwide top-grade and high-tech enterprises for High Quality China Fiberglass Mesh India/Fiberglass Woven Fabric/ Glass Fiber Reinforced Concrete, Welcome your visiting and any your inquires,sincerely hope we can have chance to cooperate with you and we can build-up prolonged perfectly organization connection along with you.

High Quality China Glass Fiber Mesh, Fiber Glass, Our product quality is one of the major concerns and has been produced to meet the customer’s standards. “Customer services and relationship” is another important area which we understand good communication and relationships with our customers is the most significant power to run it as a long term business.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.