The global composites market continues to evolve, with high-performance materials becoming the backbone of the automotive, aerospace, and renewable energy sectors. At the heart of this revolution is fiberglass roving. Whether you are involved in pultrusion, filament winding, or spray-up processes, the quality of your glass fiber roving directly dictates the structural integrity and longevity of the finished product.

Selecting the right partner is more than just looking at a catalog; it requires a deep dive into technical specifications, manufacturing consistency, and logistics. Below are the seven key factors you must evaluate when choosing a glass roving supplier.

1. Material Grade and Chemical Composition

The first step in evaluation is determining the glass type the supplier provides. The chemical composition of the glass affects everything from tensile strength to acid resistance.

E Glass Roving: The industry standard. E glass roving offers excellent electrical insulation and mechanical strength. It is the most cost-effective solution for general-purpose composites.

E Glass Direct Roving: A more refined version of E-glass, e glass direct roving is designed for high-tension applications like pultrusion, where consistent filament diameter is critical.

S Glass Roving: When high-end performance is required, s glass roving (high-strength glass) is the choice. It provides significantly higher tensile strength and modulus compared to E-glass, though at a higher fiberglass roving price.

| Property | E-Glass | S-Glass |

| Tensile Strength (MPa) | ~3,400 | ~4,800 |

| Elastic Modulus (GPa) | ~72 | ~86 |

| Temperature Resistance | Moderate | High |

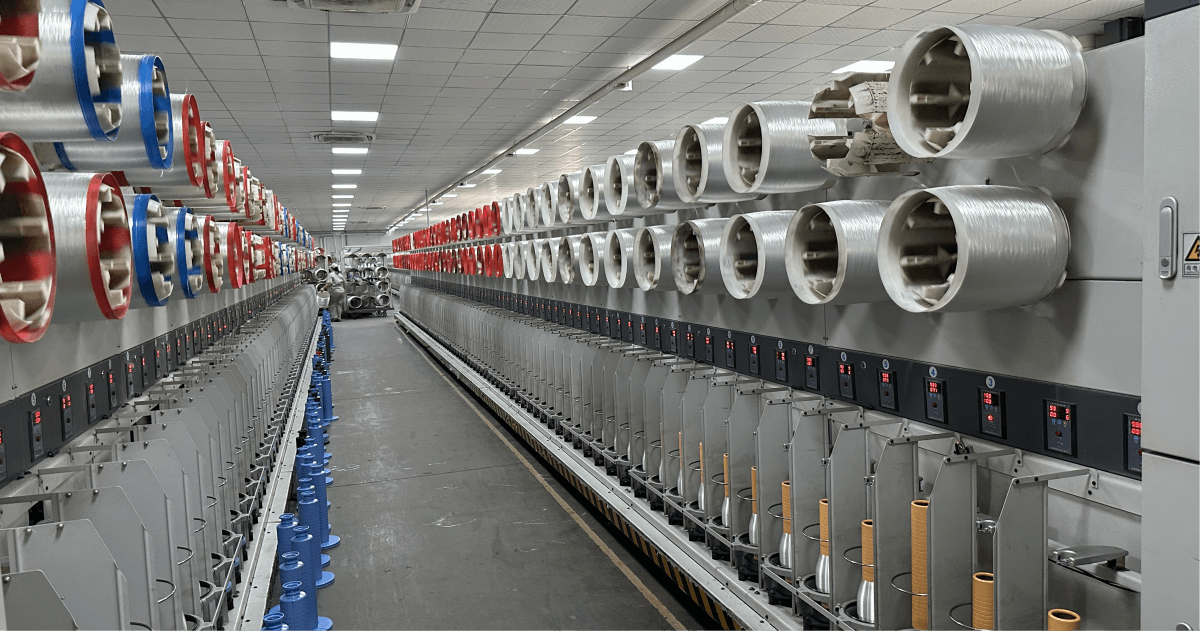

2. Product Architecture: Direct vs. Assembled Roving

Understanding the difference between direct roving and fiberglass assembled roving is vital for your production line.

Fiberglass Direct Roving: This consists of a single strand of continuous filaments. It is preferred for filament winding and pultrusion because it offers high mechanical strength and excellent resin wet-out.

Fiberglass Assembled Roving: Also known as multi-end roving, this is created by gathering multiple small strands into a single bundle. It is typically used for chopping applications, such as SMC (Sheet Molding Compound) or centrifugal casting.

A versatile supplier should offer both, including specialized continuous roving fiberglass options that ensure no breaks during high-speed manufacturing cycles.

3. Process Compatibility: The “Gun Roving” Specialty

If your facility utilizes spray-up processes, you need to evaluate the supplier’s fiberglass gun roving (also referred to as gun roving fiberglass). Not all rovings are designed to be chopped.

A high-quality gun roving must possess:

(1) Low Static: To prevent the fibers from sticking to the fiberglass roving gun during the chopping process.

(2) Excellent Lay-flat: The chopped strands must lay flat against the mold without “springing back.”

(3) Fast Wet-out: The ability of the fiberglass roving roll strands to absorb resin quickly ($t < 30$ seconds in standard tests).

If a supplier cannot provide data on the “choppability” of their fiberglass roving gun materials, they may not be the right partner for spray-up applications.

4. Resin Compatibility and Sizing Chemistry

The “sizing” is a chemical coating applied to the glass fiber roving during manufacturing. It acts as a bridge between the glass and the resin. You must ensure the supplier’s sizing is compatible with your specific resin system (Polyester, Vinyl Ester, or Epoxy).

Pro Tip: Incompatible sizing can lead to delamination. Always ask for a “Sizing Compatibility Sheet.” For instance, a fiberglass direct roving optimized for epoxy will perform poorly in a polyester-based pultrusion process.

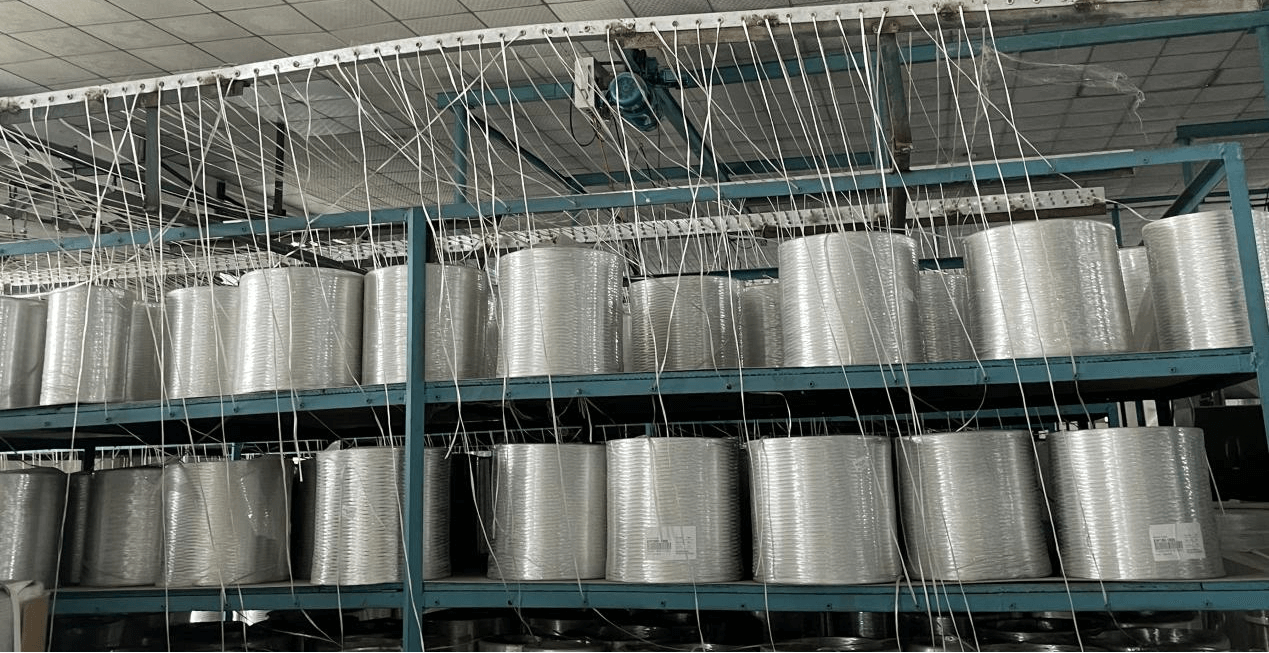

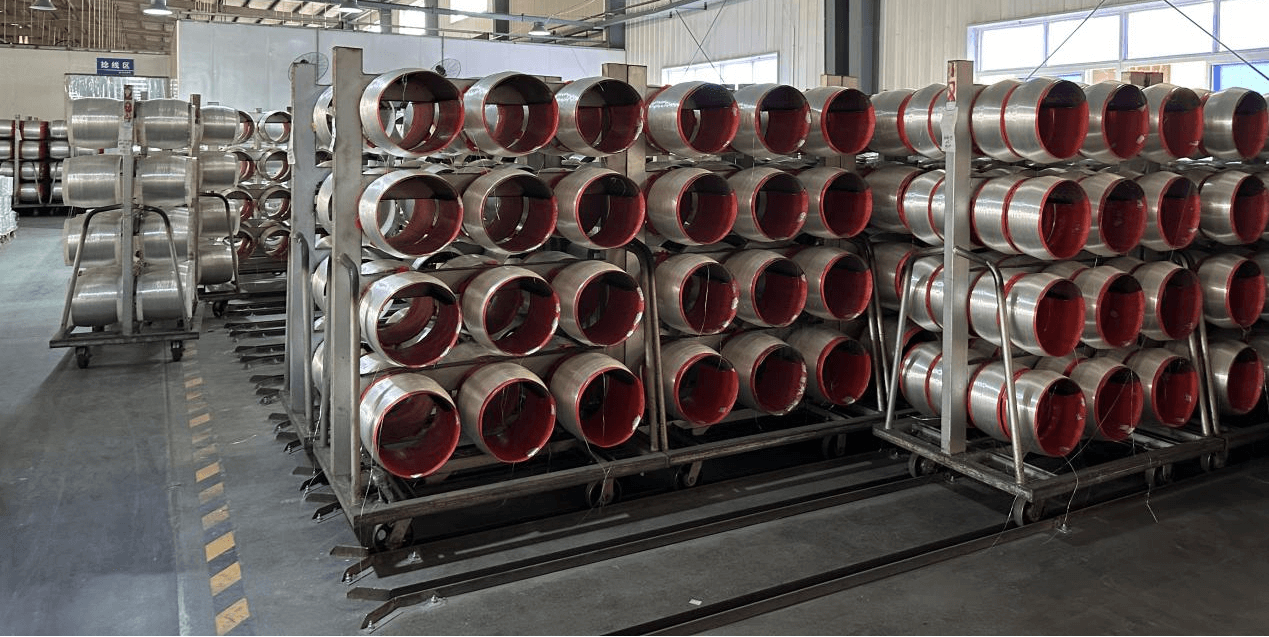

5. Manufacturing Consistency and Roll Quality

When you receive a fiberglass roving roll, its physical condition speaks volumes about the supplier’s quality control. Look for the following:

Linear Density Precision: To ensure structural uniformity in the final composite, the fiber’s linear mass (Tex/Yield) must exhibit exceptional stability, with fluctuations strictly capped at a ±5% variance from the nominal specification.

Catenary: All strands in the roving should have equal tension to avoid sagging during processing.

Internal vs. External Unwinding: Ensure the fiberglass roving roll unwinds smoothly without knotting, which can cause machine downtime.

6. Evaluating the “Fiberglass Roving Price” vs. Total Value

While the fiberglass roving price is a major factor in procurement, it should never be the only factor. Cheap roving often results in:

Higher waste due to fuzz (fiber breakage).

Increased resin consumption (poor wet-out).

Potential product failure and liability.

When comparing quotes, calculate the Total Cost of Ownership (TCO). A slightly more expensive e glass direct roving that reduces your scrap rate by 10% is actually the more economical choice.

7. Supplier R&D and Technical Support

Finally, evaluate the supplier’s ability to innovate. Are they developing new continuous roving fiberglass technologies to reduce weight? Can they help you troubleshoot issues with your gun roving spray patterns?

A reliable supplier acts as a partner. They should provide:

CoA (Certificate of Analysis): For every batch.

On-site Technical Support: To optimize your machinery for their specific fiberglass roving.

Customization: The ability to adjust Tex or sizing for specialized projects.

Conclusion

Choosing the right fiberglass roving supplier is a strategic decision that impacts your manufacturing efficiency and product quality. By focusing on material grades (like e glass roving), process-specific needs (like gun roving), and the overall technical integrity of the fiberglass direct roving, you can secure a supply chain that supports long-term growth.

Remember, the best supplier isn’t just the one with the lowest fiberglass roving price, but the one whose glass roving technology seamlessly integrates with your production goals.

Would you like me to generate a technical RFQ (Request for Quote) template that you can use to vet your potential fiberglass suppliers?

If you need,you can connect with me:

Email:marketing@frp-cqdj.com

WhatsApp: +8615823184699

Web: www.frp-cqdj.com

Post time: Jan-23-2026