Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

Fiberglass spray-up roving features:

·Excellent choppability and dispersion

·Good anti-static property

·Fast and complete wet-out ensure easy roll-out and rapid air release.

·Excellent mechanical properties of composite parts

·Excellent hydrolysis resistance of composite parts

| Glass type | E6-Fiberglass spray-up roving | |||

| Sizing type | Silane | |||

| Typical filament diameter (um) | 11 | 13 | ||

| Typical linear density (tex) | 2400 | 3000 | 4800 | |

| Example | E6R13-2400-180 | |||

| Item | Linear density variation | Moisture content | Size content | Stiffness |

| Unit | % | % | % | mm |

| Test method | ISO 1889 | ISO 3344 | ISO 1887 | ISO 3375 |

| Standard Range | ± 4 | ≤ 0.07 | 1.00 ± 0.15 | 140 ± 20 |

The product is best used within 12 months after production and should be kept in the original package before use.

·Care should be taken when using the product to prevent it from being scratched or damaged.

·The temperature and humidity of the product should be conditioned to be close to or equal to the ambient temperature and humidity before use, and the ambient temperature and humidity should be properly controlled during use.

We have many types of fiberglass roving: panel roving, spray up roving, SMC roving, direct roving,c glass roving, and fiberglass roving for chopping.

| Item | unit | Standard | |||

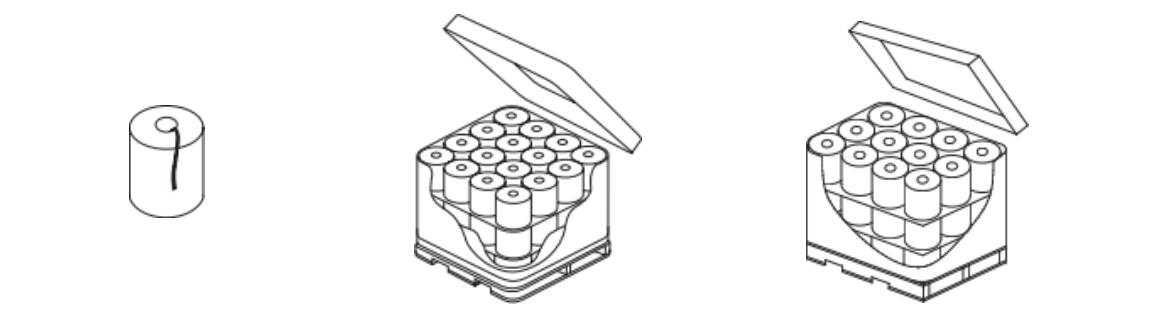

| Typical packaging method | / | Packed on pallets. | |||

| Typical package height | mm (in) | 260 (10.2) | |||

| Package inner diameter | mm (in) | 100 (3.9) | |||

| Typical package outer diameter | mm (in) | 280 (11.0) | 310 (12.2) | ||

| Typical package weight | kg (lb) | 17.5 (37.5) | 23 (50.7) | ||

| Number of layers | (layer) | 3 | 4 | 3 | 4 |

| Number of packages per layer | 个 (pcs) | 16 | 12 | ||

| Number of packages per pallet | 个 (pcs) | 48 | 64 | 36 | 48 |

| Net weight per pallet | kg (lb) | 840 (1851.9) | 1120 (2469.2) | 828 (1825.4) | 1104 (2433.9) |

| Fiberglass spray-up roving Pallet length | mm (in) | 1140 (44.9) | 1270 (50.0) | ||

| Fiberglass spray-up roving Pallet width | mm (in) | 1140 (44.9) | 960 (37.8) | ||

| Fiberglass spray-up roving Pallet height | mm (in) | 940 (37.0) | 1200 (47.2) | 940 (37.0) | 1200 (47.2) |

Unless otherwise specified, the fiberglass products should be stored in a dry, cool, and moisture-proof area. The best temperature and humidity should be maintained at -10℃~35℃ and ≤80% respectively. To ensure safety and avoid damage to the product, the pallets should be stacked not more than three layers high. When the pallets are stacked in two or three layers, special care should be taken to correctly and smoothly move the upper pallet.

Looking for high-quality fiberglass spray-up roving? Look no further! Our Fiberglass spray-up roving is specifically designed for use in spray-up applications, providing excellent strength and durability. With its superior wet-out capability, it ensures even distribution of resin, resulting in a smooth and seamless finish.

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.