In the world of composite manufacturing and repair, the “reinforcement” is the backbone of your structure. Whether you are building a marine hull, repairing an automotive body panel, or fabricating industrial tanks, selecting the correct fiberglass mat types is the difference between a high-performance part and a structural failure.

From the fine fiberglass surface tissue used for aesthetic finishes to the heavy-duty 1708 fiberglass mat used in structural laminates, this guide breaks down everything you need to know about modern glass fiber reinforcements.

1. Chopped Strand Mat (CSM): The Industry Workhorse

Chopped strand mat (CSM) is the most common form of reinforcement used in the “open mold” process. It consists of short glass fibers (typically 1 to 2 inches long) laid randomly and held together by a chemical binder.

Emulsion vs. Powder Binders

One of the most critical distinctions in glass chopped strand mat is the binder type:

Fiberglass chopped strand mat emulsion: This uses a liquid-based binder that breaks down quickly in polyester and vinylester resins. It is flexible and easy to drape over complex curves.

Powder Binder: Often preferred for specific industrial applications where chemical resistance is a priority or when working with certain specialty resins.

Common Weights and Sizes

CSM is generally categorized by weight. In the US, the 1.5 oz fiberglass mat (1.5 ounces per square foot) is the gold standard for general repairs. Globally, this is often referred to by its metric equivalent, the csm 450 fiberglass mat (450 grams per square meter).

CSM 300 (1 oz): Ideal for thin laminates or as a transitional layer.

CSM 450 (1.5 oz): The most versatile weight for boat building and general fiberglass cloth mat applications.

600g Fibreglass Matting: A heavy-duty option for building thickness rapidly.

2. Achieving a Perfect Finish: Fiberglass Surface Mat & Tissue

If you have ever seen the “pattern” of the glass fibers showing through a finished gelcoat, you’ve witnessed “print-through.” To prevent this, professionals use a fiberglass surface mat (also known as fiberglass surface tissue or fiberglass veil mat).

This material is exceptionally thin and lightweight. It acts as a barrier between the structural reinforcement and the surface gelcoat. By using a fiberglass tissue mat, you create a resin-rich surface that:

Smooths out the texture of the underlying chopped strand matt.

Provides a high-quality, paint-ready finish.

Enhances the corrosion resistance of the laminate.

3. Structural Powerhouses: 1708 and Stitch Mats

When strength-to-weight ratio is the priority, standard CSM isn’t enough. This is where fiberglass stitch mat and biaxial materials come into play.

The 1708 fiberglass mat is a professional-grade hybrid. It consists of a 17 oz biaxial cloth (fibers running at +45° and -45°) stitched to a 0.75 oz chopped strand mat.

Why use it? The biaxial fibers provide immense structural strength, while the attached mat layer ensures a strong bond to the previous layer of the laminate.

Applications: Stringer repairs, transom replacements, and high-performance hull construction.

4. The Big Question: Is it an Epoxy Fiberglass Mat?

A common point of confusion for DIYers and professionals alike is the compatibility of fiberglass mat with epoxy resin.

Most standard fiberglass chopped strand mat rolls use a binder (the “glue” holding the short fibers together) that is designed to dissolve in the styrene found in polyester and vinylester resins. Epoxy does not contain styrene.

Pro Tip: If you use a standard emulsion CSM with epoxy, the binder will not dissolve. The mat will remain stiff, hard to work with, and the bond will be structurally inferior. For epoxy projects, always look for a non-woven fiberglass mat specifically labeled as “epoxy compatible” or use a fiberglass stitch mat, which uses mechanical stitching instead of chemical binders.

5. Formats and Buying Options: Roll, Tape, and Price

When looking for fibreglass matting for sale, the format depends on the scale of your project:

Fiberglass Mat Roll: Best for large-scale production or full boat floors. Buying a full fiberglass chopped strand mat roll significantly reduces the fiberglass mat price per square foot.

Fiberglass Mat Tape: These are narrow strips of matting, perfect for reinforcing seams, joints, or small pipe repairs.

Fiberglass Mat Cloth: Often used interchangeably in casual conversation, but technically refers to the combination of mat and woven fabrics used in a laminate schedule.

|

Product Type |

Common Weight |

Best Resin Match |

Primary Use |

|

Surface Tissue |

30g – 50g |

All Resins |

Aesthetic finish / Veil |

|

CSM 300 |

1oz (300g/m2) |

Polyester / Vinylester |

Light repair / Detailing |

|

CSM 450 |

1.5 oz (450g/m2) |

Polyester / Vinylester |

General Purpose / Marine |

|

1708 Biaxial |

25 oz total |

All Resins |

Structural / High Strength |

6. Practical Tips for Working with Fiberglass Mat

Resin Consumption: A general rule of thumb for 1.5 ounce fiberglass mat is a 2:1 or 3:1 resin-to-glass ratio by weight. Because CSM is “thirsty,” it requires more resin than woven fabrics.

Tearing vs. Cutting: When using chopped strand matt, it is often better to tear the edges rather than cut them with scissors. Torn edges create a “feathered” transition that makes seams nearly invisible in the finished laminate.

Storage: Keep your glass fiber emulsion chopped strand mat in a dry, cool environment. Humidity can affect the binder, making the mat difficult to wet out properly.

Conclusion: Finding the Right Fiberglass Mat for Sale

Whether you need the delicate touch of a fiberglass veil mat for a smooth surfboard finish or the industrial strength of 600g fibreglass matting for a chemical storage tank, understanding these materials is key to a successful build.

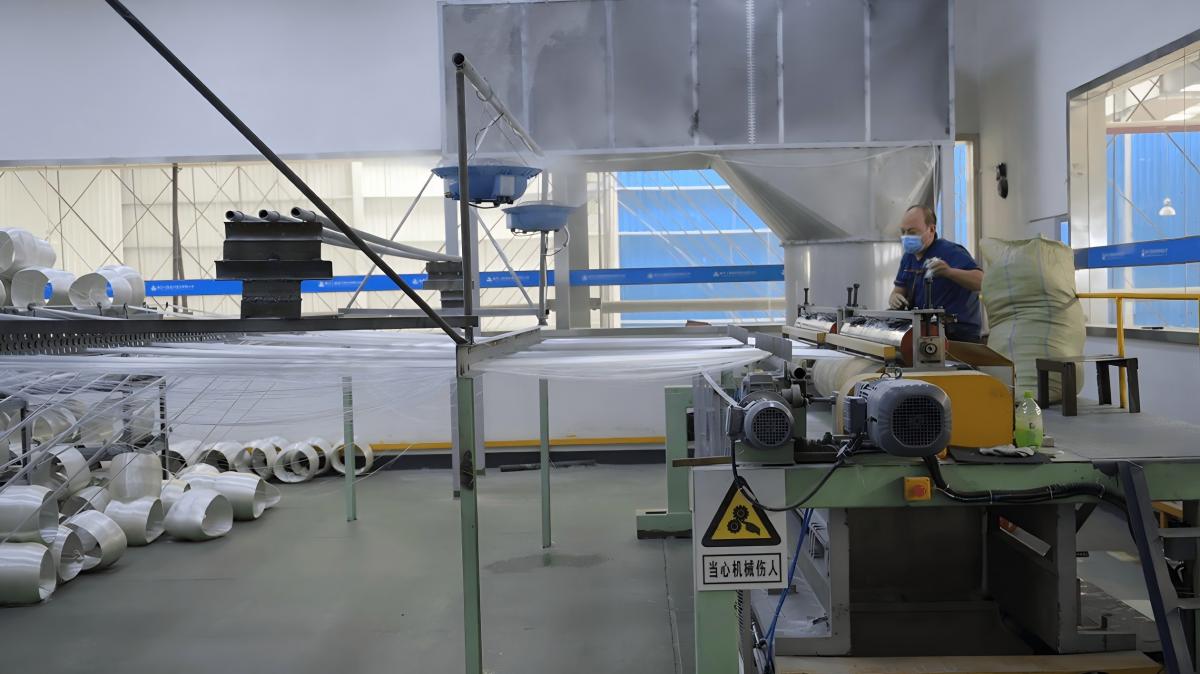

As a premier direct-to-market manufacturer, CQDJ leverages advanced production technology to deliver an exhaustive portfolio of fiberglass mats and specialty veils. From high-volume industrial rolls to custom-engineered tapes, we provide the structural backbone for your composites with unmatched consistency and factory-direct expertise.From csm 300 fiberglass for light tasks to heavy-duty fiberglass stitch mat for structural integrity, we ensure your project stands the test of time.

Are you looking for bulk pricing on fiberglass chopped strand mat rolls or need a quote for 1708 biaxial mat?

[Contact our technical team today for a custom quote and resin compatibility consultation.]

Post time: Jan-16-2026