1.Process flow

Clearing obstacles → laying out and inspecting lines → cleaning the concrete structure surface of sticking cloth → preparing and painting primer → leveling the concrete structure surface → pasting carbon fiber cloth → surface protection → applying for inspection.

2. Construction process

2.1 Obstacle clearing

2.1.1 Clean up according to the actual situation on site. The general principle is to facilitate the construction.

2.1.2 On-site quality inspectors check the cleaning status, and proceed to the next step after passing the inspection.

2.2 Paying off and checking the line

2.2.1 Release the carbon fiber cloth paste position line point position line

2.2.2 The construction can be started only after the on-site technician (foreman) has checked and released the line correctly.

2.3 Clean up the concrete structure surface of carbon fiber cloth

2.3.1 Grind the concrete surface with an angle grinder

2.3.2 Use a hair dryer to blow off the dust on the concrete surface

2.3.3 Party A, the supervisor and the person in charge of the general contractor are requested to check and accept the polished concrete surface.

2.4 Prepare and apply primer

2.4.1 Weigh accurately in strict accordance with the proportion specified by the main agent and curing agent of the supporting resin, put it into a container, and stir it evenly with a mixer.

2.5 Leveling the concrete structure surface

2.5.1 Fill the concave parts on the surface of the components with epoxy putty and repair them to a smooth surface. When using epoxy putty in defect repair, it should be constructed under the conditions of temperature above -5℃ and relative humidity less than 85%. After the putty is applied and scraped, the four convex rough lines that still exist on the surface should be smoothed with sandpaper, and the corners should be repaired to an arc with a radius of not less than 30mm.

2.6 Paste carbon fiber fabric

2.6.1 Before pasting carbon fiber materials, first confirm that the pasting surface is dry. When the temperature is below -10℃ and the relative humidity RH>85%, construction is not allowed without effective measures. In order to prevent the carbon fiber from being damaged, use a steel ruler and a wallpaper knife to cut the carbon fiber material to the specified size before pasting, and the length of each section is generally not more than 6m. In order to prevent the material from being damaged during storage, the cutting quantity of the material should be cut according to the amount of the day. The lap length of carbon fiber longitudinal joints shall not be less than 100mm. This part should be coated with more resin, and the carbon fiber does not need to be overlapped horizontally.

2.6.2 Prepare the impregnating resin and apply it evenly to the components to be pasted. The thickness of the glue is 1-3mm, and the middle is thick and the edges are thin.

2.6.3 Rolling along the fiber direction for many times to squeeze out the air bubbles, so that the impregnated resin can completely penetrate the fiber cloth.

2.6.4 The surface of carbon fiber cloth is evenly coated with impregnating resin.

2.7 Surface protection treatment

2.7.1 If the reinforcement and reinforcement components need to be fireproof, a fire-resistant coating can be applied after the resin is cured. The coating should be carried out after the initial curing of the resin, and should comply with the relevant standards and construction regulations of the coating used.

2.8 Application for inspection

2.8.1 After completion, please supervise or general contractor for acceptance. Fill in the hidden inspection information, project quality inspection approval form, please sign the general contractor and supervisor

2.8.2 Arrange all the necessary data for the project and transfer it to the general contractor to ensure the integrity of the entire project data.

3. Construction quality standards

3.1 Main control project:

The pasted carbon fiber cloth must meet the design requirements and the construction specifications of the reinforcement industry

3.2 General items:

3.2.1 For hollow drums with a diameter of more than 10mm and less than 30mm, less than 10 per square meter can be considered qualified.

3.2.2 If there are more than 10 per square meter, it is considered unqualified and needs to be repaired.

3.2.3 For hollow drums with a diameter of more than 30mm, as long as they appear, they are considered unqualified and need to be repaired.

4.Precautions for construction

4.1 Safety precautions for pasting carbon fiber cloth

4.1.1 The A and B components of the matching resin should be sealed and stored away from the fire source and avoid direct sunlight.

4.1.2 Operators should wear work clothes and protective masks.

4.1.3 The construction site should be equipped with all kinds of necessary fire extinguishers for rescue.

4.2 Safety protection measures

4.2.1 At the dangerous place, two guardrails shall be set at the edge, and a red sign light shall be set at night.

4.2.2 Each construction frame shall be erected in strict accordance with the scaffolding safety technical protection standards and specifications.

4.3 Fire management practices

4.3.1 Strengthen the fire protection work in the project site to ensure the normal construction and production, and protect the safety of people’s lives and property.

4.3.2 Fire-fighting buckets, irons, hooks, shovels and other fire-fighting appliances should be installed on site.

4.3.3 Establish a fire protection responsibility system at all levels, formulate a fire protection system, and supervise its strict implementation.

4.3.4 Establish a fire certificate system for applying for open flames, prohibit smoking at the construction site, and control the fire source.

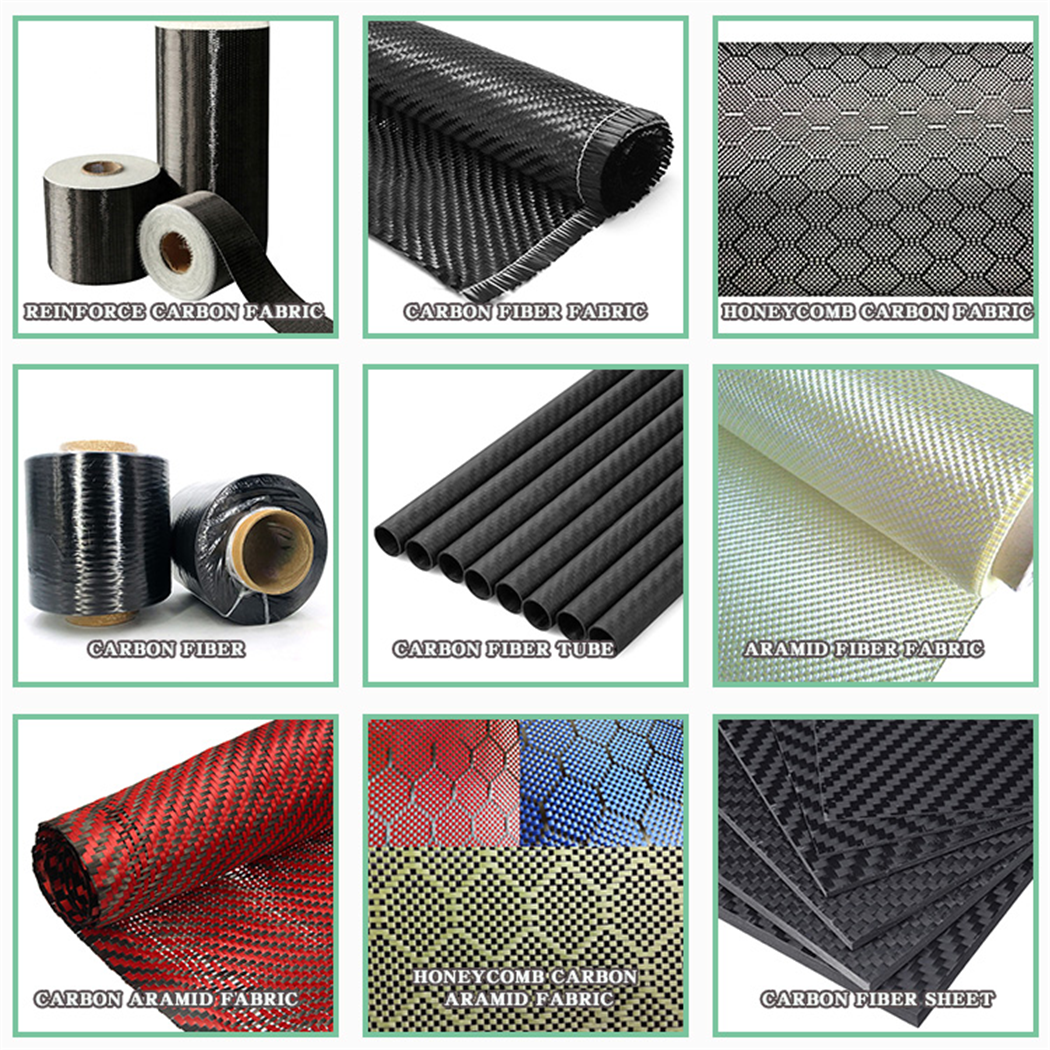

The types of our carbon fiber products are as follows:

Reinforce carbon fabric

Honeycomb carbon fabric

Carbon fiber roving

Carbon fiber tube

Carbon aramid fabric

Honeycomb carbon aramid fabric

We also produce fiberglass direct roving, fiberglass mats, fiberglass mesh, and fiberglass woven roving.

Please contact:

Phone number:+8615823184699

Telephone number: +8602367853804

Email:marketing@frp-cqdj.com

Post time: May-18-2022