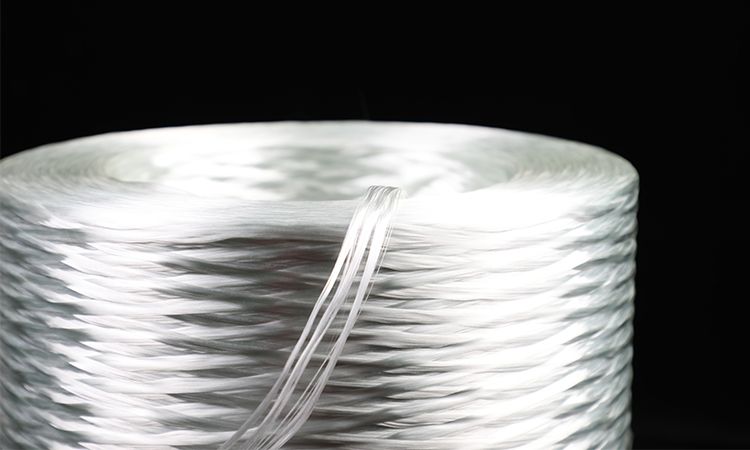

Fiberglass direct roving is a continuous strand of glass fibers that are twisted together and wound into a cylindrical package. It is used in applications where a high degree of mechanical strength is required, such as composite materials, automotive components, and wind turbine blades. Additionally, direct roving is ideal for pultrusion, filament winding, and sheet molding compound (SMC).

Fiberglass gun roving, on the other hand, is a chopped strand of glass fibers that are fed through a pneumatic gun to spray onto a surface. It is typically used in applications that require a quick buildup of material, such as boat building, swimming pool manufacturing, and spray-up molding.

When choosing between fiberglass direct roving and fiberglass gun roving, there are several factors to consider:

- Manufacturing Process: Consider the manufacturing process being used. Direct roving is the ideal choice for manufacturing processes that require high-strength and stiffness, such as pultrusion or filament winding. Whereas, gun roving is better suited for the quick buildup of material on a surface, making it more suited for spray-up molding applications.

- Technical Requirements: Consider the technical requirements of the product. If you need a product that has a high strength-to-weight ratio, such as wind turbine blades, then direct roving is the right choice. However, if the product requires a quick buildup of material or a thick coating, such as a swimming pool, then gun roving should be considered.

- Product Performance: The desired performance of the product also plays a role in the selection of roving. Direct roving can provide higher mechanical strength and stiffness, which is important in applications where the product must withstand heavy loads. Gun roving, on the other hand, provides a higher coverage area, which is ideal for products that require a thick coating.

- Cost: Finally, consider the cost of the roving. Direct roving is generally more expensive than gun roving, so it’s important to weigh the benefits of both options against the cost. Overall, choosing between fiberglass direct roving and fiberglass gun roving depends on the specific application and its requirements. By understanding the processes, performance, and cost of each material, manufacturers can make an informed decision on which type of roving on which to rely.

Contact Us:

Phone number/WhatsApp:+8615823184699

Email: marketing@frp-cqdj.com

Website: www.frp-cqdj.com

Post time: Jun-17-2023