Fiberglass(also as glass fiber) is a new type of inorganic non-metallic material with superior performance.

Glass fiber is widely used and continues to expand. In the short term, the high growth of the four major downstream demand industries (electronic appliances, new energy vehicles, wind power, and 5G) will bring continuous growth. In the long run, glass fiber and its products will grow rapidly in the future, the penetration rate of various application fields will increase, and the industry market space will be broad.

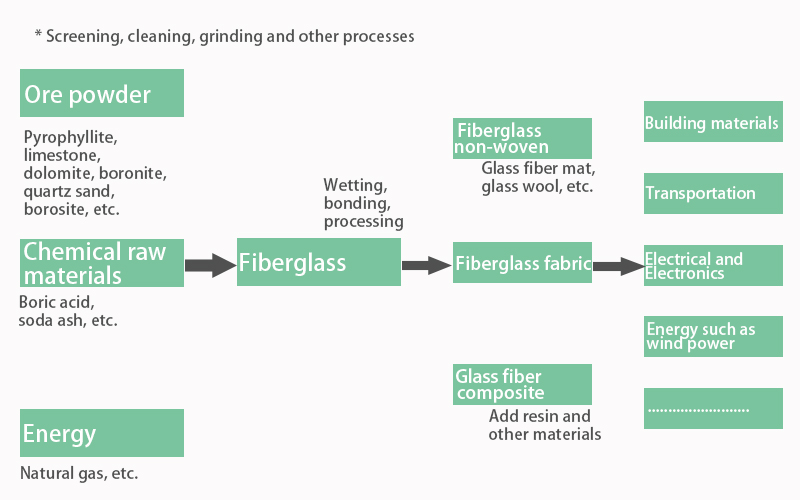

At present, my country has formed a complete industrial chain of glass fiber (original yarn), glass fiber products and glass fiber composite materials, which is divided into three areas: upper, middle and lower.

Upstream provides necessary raw materials for glass fiber production, involving ore mining, energy, chemical and other industries.

Glass fiber production is located in the middle of the industrial chain. Through the use of upstream raw materials and unique processes, glass fiber roving and glass fiber textile and non-woven products are produced. These products are further processed to become terminal composite products.

Downstream industries involve infrastructure, environmental protection, energy conservation, new energy, and transportation.

Fiberglass industry chain:

Fiberglass: Upstream Raw Materials

In the cost structure of glass fiber products, the supply of upstream raw materials of glass fiber is relatively abundant, and the cost accounts for a large proportion.

The upstream raw materials of glass fiber are mainly ore raw materials such as pyrophyllite, kaolin, limestone, etc., which are manufactured by high temperature melting, wire drawing, winding, weaving and other processes, and are used in downstream industries by forming glass fiber products and glass fiber composite materials.

My country’s quartz sand and pyrophyllite have great resource advantages, and the price volatility is small, which has little impact on the overall glass fiber industry.

Power energy is the second largest factor in glass fiber production, mainly natural gas, platinum and rhodium consumables. In the process of producing glass fiber, pool kiln drawing enterprises have a strong dependence on heating energy, such as natural gas, electricity, and production materials such as platinum-rhodium alloy bushings.

Midstream: Fiberglass Products

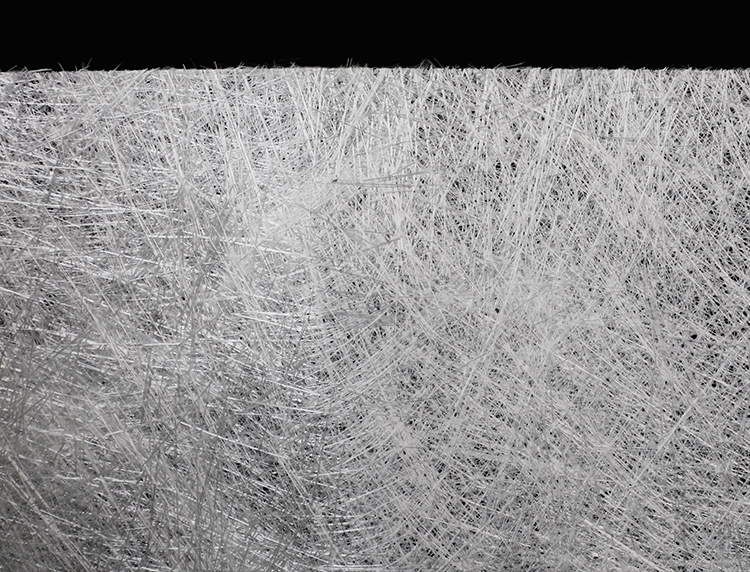

Glass fiber products are mainly divided into non-woven products and textile products.

Non-woven products refer to products made of glass fibers by non-woven methods (mechanical, chemical or thermal methods), mainly including glass fiber mats (such as chopped strand mats,

continuous mats, needle-punched mats, etc.) and milled fibers.

Two-level classification of glass fiber composite materials:

|

Primary classification |

Secondary classification |

Primary classification |

Secondary classification |

||

|

Glass fiber products |

Glass fiber non-woven products |

Chopped strands mat |

Glass fiber composite |

Glass fiber deep processing products |

CCL |

|

Fiberglass Wet Laminated mat |

Insulation Materials |

||||

|

Fiberglass Continuous Mat |

Dip Coated Products |

||||

|

Fiberglass Stitched Mat |

Thermosetting Reinforced Plastic Products |

||||

|

Fiberglass Needled Mat |

Thermoplastic Reinforced Plastic Products |

||||

|

Fiberglass fabric |

Fiberglass woven roving |

Enhanced building materials |

|||

|

Fiberglass mesh |

|

||||

|

Glass fiber electronic cloth |

|

||||

Glass fiber can be divided into alkali-free, medium-alkali, high-alkali and alkali-resistant glass fiber according to the composition. Among them, alkali-free glass fiber occupies the mainstream of the market, and the production capacity accounts for more than 95%.

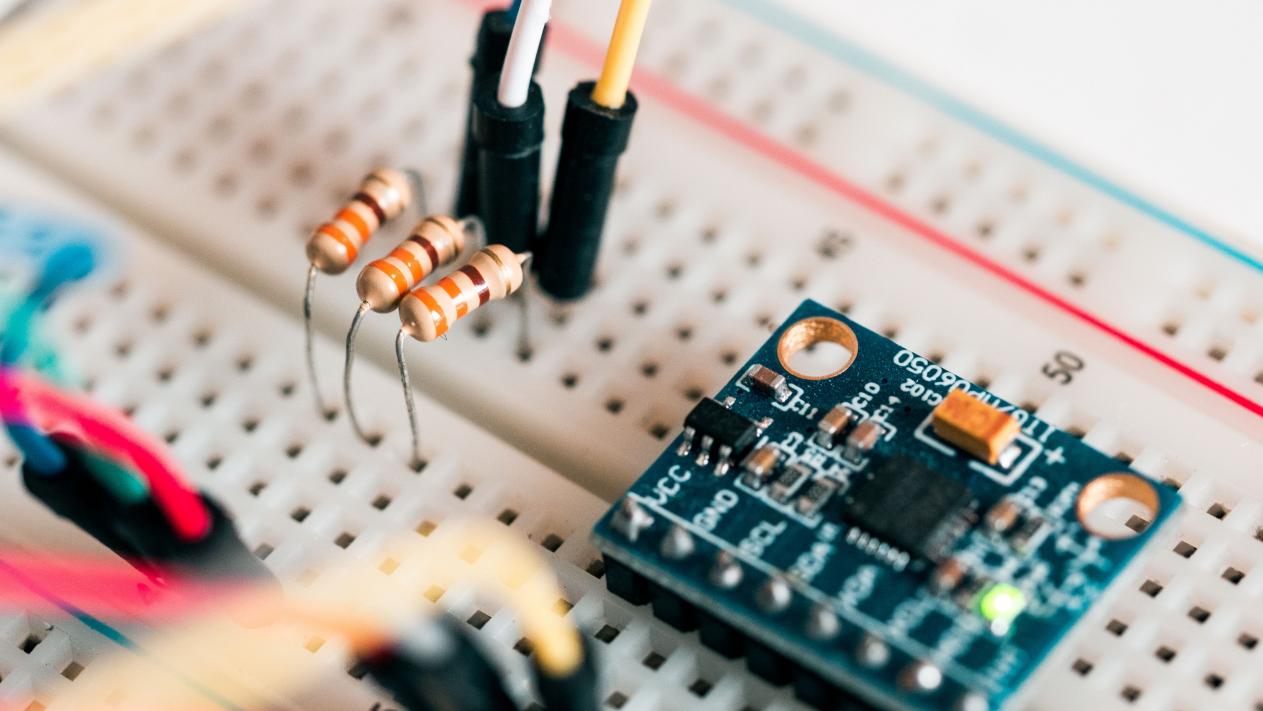

According to the size of the monofilament diameter, it can be divided into three series: roving, spun roving and electronic yarn. Among them, roving is often compounded with resin to make glass fiber reinforced plastic (glass fiber reinforced plastic); spun roving can be made into glass fiber textile products; electronic yarn is woven into glass fiber cloth, which is mainly used to manufacture copper clad laminates as raw materials for printed circuit boards.

From the perspective of the proportion of production capacity, the output of roving in my country accounts for about 70%-75%, but with the elimination and adjustment of roving production capacity, the proportion of roving gradually decreases.

Downstream application areas

Glass fiber is not the final form of downstream applications, but is used as an intermediate product and downstream products to form a glass fiber composite material to enhance the overall performance of the material.

The downstream of the glass fiber industry is very scattered and highly correlated with the macro economy.

At present, building materials, transportation, industry and wind power are the main downstream industries of glass fiber, and the four account for 87% of the glass fiber demand structure.

Under the background of “double carbon”, policies promote the adjustment of energy structure, wind power investment is expected to maintain high intensity, wind power roving demand is expected to gradually recover, and the penetration rate of new energy vehicles has steadily increased, driving the increase in the use of related glass fiber materials, and the demand side The medium and long-term growth is still relatively good.

In the wind power industry, glass fiber is mainly used in the manufacture of wind power blades and nacelle covers. China has now become the world’s largest wind power market.

The rapid development of my country’s wind power industry has driven the rapid growth of the upstream demand for glass fiber and its products. With the continuous development of the wind power industry in the future, and the implementation of a large number of wind power product production lines, the application of glass fiber has broad prospects.

Electronic glass fiber yarn is a kind of glass fiber material with good insulation, which can be made into glass fiber cloth, which is used for the production of copper clad laminate, the core substrate of printed circuit board (PCB).

Based on the current cost advantage, further promoting the construction of intelligent manufacturing plants, reducing labor costs, and reducing energy consumption through cold repair technical transformation are the main means for my country to maintain cost advantages and strengthen the cost moat.

Based on the current cost advantage, further promoting the construction of intelligent manufacturing plants, reducing labor costs, and reducing energy consumption through cold repair technical transformation are the main means for my country to maintain cost advantages and strengthen the cost moat.

According to the “14th Five-Year” development plan of China Glass Fiber Industry Association, innovation is the fundamental driving force to promote the implementation of supply-side structural reforms in the glass fiber industry. Strictly control the excessive growth of industrial production capacity; take the market as the guide, do a good job in the research and development and market expansion of glass fiber and products; focus on promoting the whole industry to upgrade to intelligence, green, differentiation and internationalization, and achieve high-quality development.

Contact Us:

Tel: +86 023-67853804

Email:marketing@frp-cqdj.com

Web: www.frp-cqdj.com

Post time: Aug-12-2022