Inquiry for Pricelist

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.

(1)HIGH-QUALITY RAW MATERIALS: Excellent raw material is selected as the raw material with high strength and good toughness.

(2)HIGH ALKALI-RESISTANCE: Smooth and bright, high toughness, no stick.

(3)THE NODES ARE NEAT: The nodes are dense and not disorderly, and the adhesion force is strong. High tensile strength.

(4)VARIOUS SPECIFICATIONS: Many colors can be customized, please consult us.

(5)MANUFACTURER DIRECT SALE: The warehouse is insufficient stock, the price is reasonable and the specification is complete, feel free to buy.

(1) Fiberglass mesh is used for wall reinforcement.

(2) Fiberglass mesh is an ideal material for outside wall heat insulation.

(3) Fiberglass mesh can be applied to bitumen as roof waterproof material, so as to strengthen the tensile strength and lifetime of bitumen.

(4) For Reinforcement of marble, mosaic, and stone, plaster.

(1) 16x16 Fiberglass mesh, 12x12 mesh, 9x9 mesh, 6x6 mesh, 4x4 mesh, 2.5x2.5 mesh

15x14 mesh, 10x10 Fiberglass mesh, 8x8 mesh, 5x4 mesh, 3x3 mesh, 1x1 mesh, and so on.

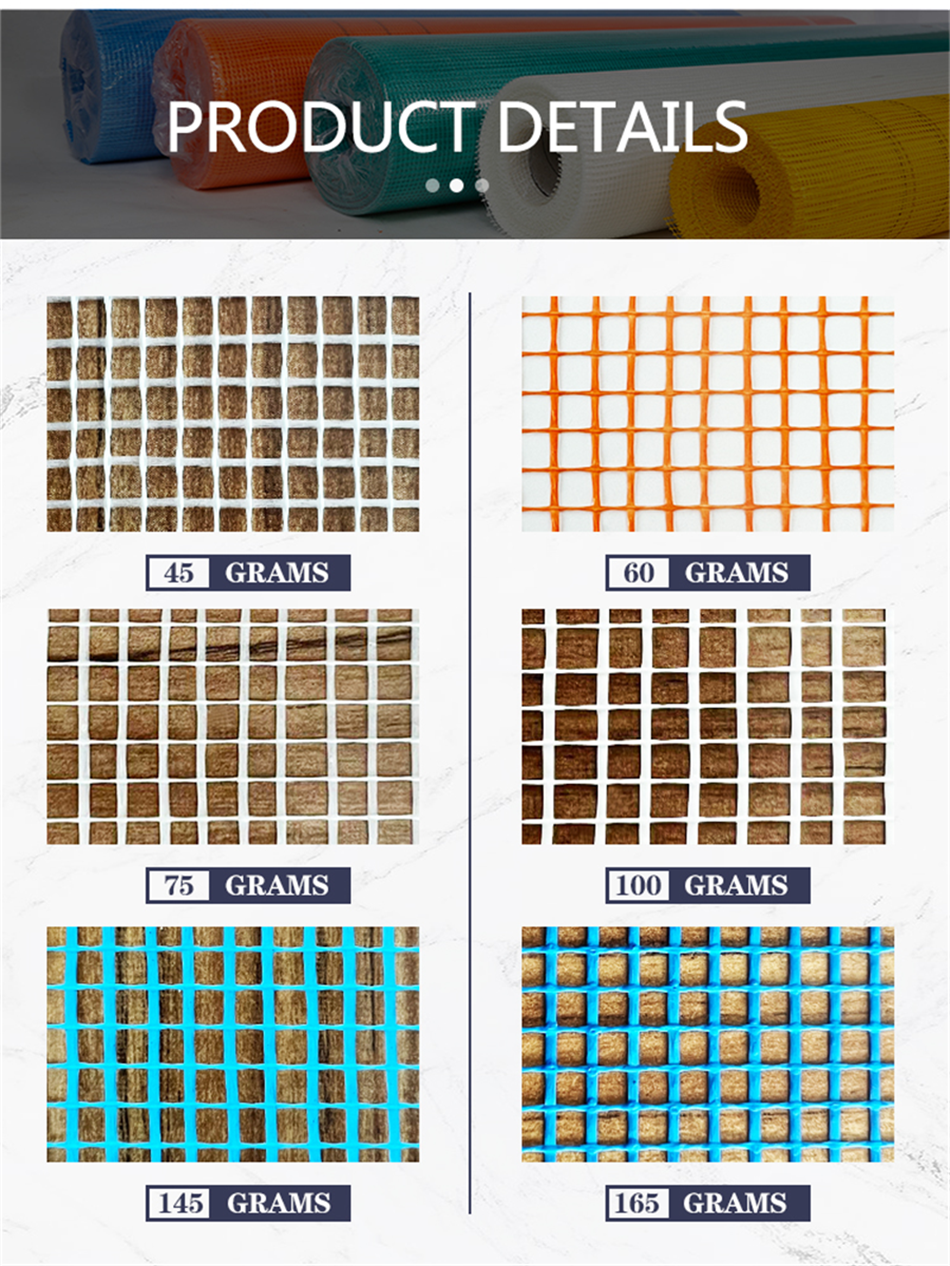

(2) Weight/sq.meter: 40g—800g

(3) Each roll length: 10m, 20m, 30m, 50m—300m

(4) Fiberglass Mesh Width: 1m—2.2m

(5) Fiberglass Mesh Color: White (standard) blue, green, orange, yellow, and others.

(6) We can produce many specifications and use different packaging according to customers' requests.

(1)Fiberglass mesh 75g / m2 or less: Used in the reinforcement of thin slurry, to eliminate small cracks and scattered throughout the surface pressure.

(2)Fiberglass mesh 110g / m2 or about: Widely used in indoor and outdoor walls, prevents the various materials (such as brick, light wood, prefabricated structure) of treatment or caused by a variety of expansion coefficients of wall crack and break.

(3)Fiberglass mesh 145g/m2 or about Used in the wall and mixed in various materials (such as brick, light wood, and prefabricated structures), to prevent cracking and scatter the whole surface pressure, especially in the external wall insulation system (EIFS ).

(4)Fiberglass mesh 160g / m2 or about Used in insulator layer of reinforcement in the mortar, through shrinkage and temperature changes by providing a space to maintain movement between the layers, prevent crack and rupture due to shrinkage or temperature change.

|

Item Number |

Yarn(Tex) |

Mesh(mm) |

Density Count/25mm |

Tensile Strength × 20cm |

Woven Structure

|

Content of resin%

|

||||

| Warp |

Weft |

Warp |

Weft |

Warp |

Weft |

Warp |

Weft |

|||

|

45g2.5x2.5 |

33×2 |

33 |

2.5 |

2.5 |

10 |

10 |

550 |

300 |

Leno |

18 |

|

60g2.5x2.5 |

40×2 |

40 |

2.5 |

2.5 |

10 |

10 |

550 |

650 |

Leno |

18 |

|

70g 5x5 |

45×2 |

200 |

5 |

5 |

5 |

5 |

550 |

850 |

Leno |

18 |

|

80g 5x5 |

67×2 |

200 |

5 |

5 |

5 |

5 |

700 |

850 |

Leno |

18 |

|

90g 5x5 |

67×2 |

250 |

5 |

5 |

5 |

5 |

700 |

1050 |

Leno |

18 |

|

110g 5x5 |

100×2 |

250 |

5 |

5 |

5 |

5 |

800 |

1050 |

Leno |

18 |

|

125g 5x5 |

134×2 |

250 |

5 |

5 |

5 |

5 |

1200 |

1300 |

Leno |

18 |

|

135g 5x5 |

134×2 |

300 |

5 |

5 |

5 |

5 |

1300 |

1400 |

Leno |

18 |

|

145g 5x5 |

134×2 |

360 |

5 |

5 |

5 |

5 |

1200 |

1300 |

Leno |

18 |

|

150g 4x5 |

134×2 |

300 |

4 |

5 |

6 |

5 |

1300 |

1300 |

Leno |

18 |

|

160g 5x5 |

134×2 |

400 |

5 |

5 |

5 |

5 |

1450 |

1600 |

Leno |

18 |

|

160g 4x4 |

134×2 |

300 |

4 |

4 |

6 |

6 |

1550 |

1650 |

Leno |

18 |

|

165g 4x5 |

134×2 |

350 |

4 |

5 |

6 |

5 |

1300 |

1300 |

Leno |

18 |

· Fiberglass mesh is usually wrapped in a polyethylene bag, then 4 rolls are put into a suitable corrugated carton.

· A 20 feet standard container can fill about 70000 m2 of fiberglass mesh, and a 40 feet container can fill about 15000 m2 of fiberglass net cloth.

· Fiberglass mesh should be stored in a cool, dry, water-proof area. It is recommended that the room temperature and humidity be always maintained at 10℃ to 30℃ and 50% to 75% respectively.

· Please keep the product in its original packaging before being used for no more than 12 months, avoiding moisture absorption.

· Delivery Detail:15-20 days after receiving the advance payment.

In addition to this, our popular products are fiberglass roving, fiberglass mats, and mold-release wax. Email if necessary

For inquiries about our products or pricelist, please leave your email to us and we will be in touch within 24 hours.